Everything you need to know about metal clamps

Metal clamps are an integral part of pipelines, necessary for their reliable fixation or repair in case of leaks. Repair and crimping steel clamps-tie, iron clamps with nut and screw solve many problems in piping systems.

Peculiarities

Metal pipe clamps are ubiquitous. With their help you can:

- securely fix the pipe to the wall or supporting beam;

- quickly eliminate the leak through the crack in the pipe wall;

- to give tightness to joints and fittings;

- fix a rubber or reinforced hose to the fitting;

- fix plumbing hoses and corrugations;

- remove fistulas in pipes that have formed due to stray currents;

- and even mechanically fasten some parts.

However, their direct purpose is to ensure the stable operation of pipelines. Therefore, they have become widespread in various fields, such as:

- household and communal;

- hydraulic structures;

- engineering industry;

- motorcycle and automobile construction;

- energy;

- gas facilities;

- design and various crafts.

These fasteners must be reliable and durable. And also - to meet quality standards. Therefore, they are manufactured according to the requirements of GOST 24137-80.

This document states:

- limiting pipe diameters for which the clamp is designed;

- thread diameter (the fastening nut is selected according to it);

- the length of the thread (the thickness of the support depends on it, to which the pipe can be attached);

- product weight (also an important parameter, especially for transport);

- manufacturing precision;

- links to other documents (which define storage conditions, labeling, etc.).

When buying a standard product, you can be sure of its quality. But it will not be superfluous to ask the seller for a certificate.

Species overview

If such a retainer is chosen incorrectly, the goal will not be achieved. Therefore, before buying, you need to familiarize yourself with their classification. Clamps are divided according to several criteria.

By tasks

According to the type of tasks to be solved, the clamps are divided into 2 groups - fastening and repair.

- Fasteners. Their task is to securely fix the pipeline on the supporting base. Therefore, such a clamp must be strong, while the tightness of the connection and the speed of installation are not required.

In turn, there are 2 types of fasteners.

- Mounting. They are installed in the wall before the pipes are laid. They necessarily fix the risers of the water supply and sewerage system.

- Crimp. They serve to insert new pipe sections into an already finished system. For example, they fix the hoses to the nozzles.

For installation in the wall, the mounting clamps are equipped with shanks, which include:

- a smooth rod, which is welded to the reinforcement or inserted into the hole and poured with concrete;

- threaded rod for dowels;

- rod with metric thread and lock nut;

- welded nut;

- hole without thread.

For fastening, for example, a hose to a fitting, a shank is not needed. Therefore, the crimp clamps do not have it, but at the same time they retain high strength and reliability of the installation.

In addition to single ones, there are also double fastening clamps that fix two pipes at once.

Their advantage is simpler installation, because instead of 2 holes in the wall, you only need to drill one.

- Repair. They are designed to quickly fix leaks. Such clamps are equipped with a rubber seal that fits tightly on the pipe and closes the leak, and convenient clamps.These fittings are not durable and are used as a temporary solution. But sometimes they are able to work for years.

To install them, it is not necessary to stop the circulation of fluid in the system. They are suitable for metal and plastic pipes and can eliminate:

- fistulas (a fistula is a hole in a wall that is caused by system wear, increased fluid pressure, or pitting);

- fractures;

- cracks;

- mechanical and other damage.

The main characteristics of these clamps are the calculated diameter of the pipe and the length of the clamp (it is chosen according to the amount of damage). The clamp must completely and "with a margin" block the leak.

The disadvantage is that the area to be repaired must be straight. On bends and branches, such a clamp will not ensure tightness.

It is advisable to immediately buy a set of repair clamps so that in an accident you do not have to urgently look for this part.

And such a repair kit needs to be updated over time: if nothing happens to the iron clips, then the rubber part may dry out.

By type of attachment

The task of the fasteners is to securely fix the clamp on the pipeline. And here you need to take into account the modes of operation of the pipe, because they need a different type of fixation.

- Movable (floating). It is designed for changing operating conditions, such as heating and hot water systems. When heated, the diameter of the pipe increases, if the fit is rigid, cracks will appear. Flexible clamps eliminate this problem as they can deform slightly.

- Hard (motionless). It is used under constant conditions, as well as on folds and branches. There is no possibility of movement, but the fastening is stronger.

This applies to purely iron models. If a thick rubber pad is used, a floating hold can be achieved regardless of the clamp design. Especially if you don't tighten too much.

By design

Clamps differ in the shape of their components.

- U-shaped. It is a bracket, on the ends of which a strap is put on. Such a clamp is tightened with two nuts and can withstand heavy loads. It is usually used for repairing pipelines, but it is also suitable for fastening.

- With a clip. Basically, these clamps are used when installing PVC pipes. They come with a wedge or a snap-lock for connection. They are not designed for heavy loads, but they are very convenient for installation.

- Split ring (one-way type). This is an iron bracket, the bent ends of which are connected with a bolt (or several). The simplest type that is easy to make yourself. The disadvantage is that it is not universal and is only suitable for a pipe of a certain diameter.

- Several half rings (2-sided). The clamp consists of 2 or more segments that are bolted together. The kit includes washers, nuts, and often a rubber pad. Suitable for different pipe sizes, but after installation, the gap between the segments should not be too large.

- With fixing pin. This clamp is designed to secure the pipelines. It usually consists of 2 half-rings, one of which is equipped with a shank for installation in the wall.

And since the material and purpose of pipes is different, then the clamping force for them should be different. Here the rule applies - the more convenient the installation, the less the clamping force. Therefore, you should not choose models with excessive clamping force (they can lead to cracks), sometimes simpler designs are enough.

Choose the correct fastening mechanism and, as a result, the type of clamp.

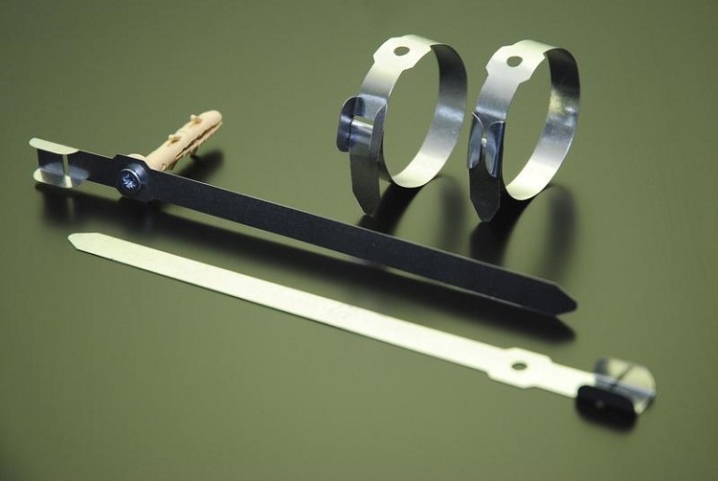

- Spring loaded. It looks like a steel ring with two jaws (or brackets). To install, you need to squeeze the staples with pliers, put it on the pipe and release it smoothly. The clamp will be compressed - you get a reliable and flexible connection. In addition, it does not need to be tightened during operation.

- Worm gear (tape, clamp-tie). This is a galvanized metal strip with projections or (less securely) slots on it.To tighten, you need to tighten the screw or thumb. This type has become widespread due to the simplicity and ease of installation and reliable fixation of the branch pipes. In addition, the material of manufacture is different:

- W1 - the tape is made of galvanized steel;

- W2 - the tape is easily magnetized (while the screw is steel);

- W4 - steel, not amenable to magnetization;

- W5 - the clamp is made of non-magnetic and stainless steel.

Sometimes, instead of a screw, the clamps are equipped with an eccentric clip with a snap.

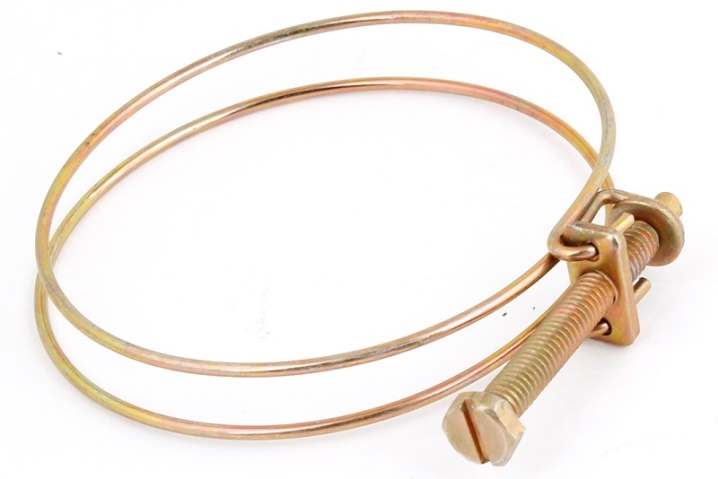

- Wire (spiral). It consists of several wheels made of wire, which are connected by a screw tightening mechanism. This clamp is well suited for corrugated and reinforced hoses. For soft hoses, do not use it, otherwise, if tightly tightened, the wire can severely deform or cut the hose.

- Power clamp. A metal tape with a cutout, which is equipped with a tightening structure. The clamp is pulled together with one screw and nut. This type is used for fixing and repairing pipelines for various purposes.

- Reinforced. It differs from other fasteners only in thicker stamped parts. Sometimes such a clamp is equipped with an opening hinge, since its sturdy body does not bend.

- Pipe. It looks like several equal half-rings, which are tightened with screws. Usually they are 1- or double-sided, but for large diameter pipes the number of segments can be 3, 4 or more. At the same time, 1-sided models are more demanding on the pipe diameter, while 2-sided models are suitable for different pipe sizes.

When choosing, keep in mind that the names of the clamps in different stores may differ. So choose by looks or catalogs with photos.

Dimensions and weight

There are a large number of clamp models on the market, while the range of possible diameters for all designs is different.

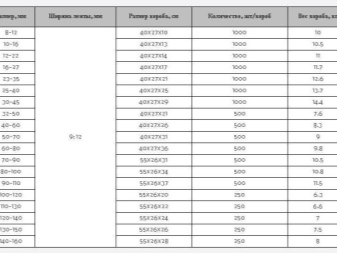

- Worm gear. The smallest clamping diameter is 8 mm, the largest is 160 mm.

- Screw - 18-76 mm.

- Spring-loaded - 13-80 mm.

- Spiral - 38-500 mm.

At the same time, worm clamps have the largest adjustment range. This means that one and the same clamp can be used to secure a pipe both 110 mm and 200 mm in diameter. After installation, the excess part of the clamp is simply cut off. This is actively used by installers.

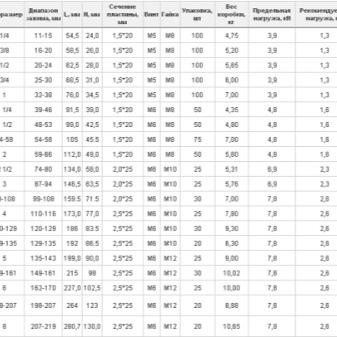

The sizes of all types of clamps change stepwise and are prescribed in GOST. It also indicates the width of the tape, the mass and the maximum load.

Standard sizes of worm gear clamps are shown in the table.

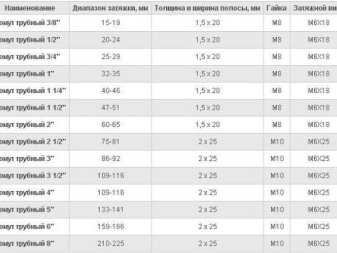

The diameter of the plumbing (pipe) clamps is usually indicated in inches (1 inch - 25.4 mm). This is convenient because the size of the pipes is also counted in inches.

For metal models with a hairpin, the number of standard sizes is slightly different.

It should be borne in mind that with an increase in diameter, the width and wall thickness always increase, especially in repair models. This is important when there is a lack of working space or a short pipe length.

The width of the fastening clamps is usually 20-25 mm.

The internal thread of the union nuts usually ranges from M6 to M10. It makes no sense to put large nuts, since the size of the clamp increases greatly.

And if the fastening force is not enough, the number of screws is increased.

Nuances of operation

No matter how good modern clamps are, they require a competent choice and, importantly, correct operation. A few tips from experts will definitely come in handy.

Choose a means of fastening to the transverse shape of the pipe. Most of the clamps are round, but there are also models with a square profile.

Pay attention to the edges before choosing. They must not be sharp, otherwise the clamp will cut the rubber hose during installation. If the edges are sharp, they will need to be filed off.

When ordering from the online store, it is advisable to indicate the diameter of the pipe on which the clamp will be installed. This is especially true for one-sided models.

It is always advisable to use rubber-gasket clamps. Their advantages:

- they reduce vibration and noise during pipeline operation;

- the probability of damaging the pipe is completely excluded;

- even with rigid clamp structures, the “floating” fastening is maintained.

It is recommended to lubricate the screw connections with machine oil or silicone oil before installation. This will not only make the screws easier to tighten, but will also prevent further corrosion. Just keep in mind that industrial oil corrodes some types of rubber.

When mounting, always measure the applied force and the dimensions of the fasteners. In addition, the spring clip may jump off and fly to the side when compressed. Be careful.

Make sure that no dirt or dust gets on the work surface. Not only will it scratch the pipe, but it can also lead to premature corrosion.

Tighten screw connections periodically, especially if the pipe is vibrated. If the tool is difficult to operate, buy a wing clamp instead of the screw. No tool is required to tighten it.

Do not allow the screws to become dirty with dust. This not only extends the service life, but also allows the clamp to be reused after removal. The clamp is in good condition without signs of corrosion and is designed for a minimum of 50 assembly-disassembly cycles.

And always follow safety precautions. And also do not skimp on fasteners, because most often the pipe breaks down precisely at the joints.

And high-quality fittings will add reliability to the entire system.

An overview of useful tools for working with clamps from China in the video below.

The comment was sent successfully.