Types of cable ties and their applications

As the requirements for the quality and the execution of work on the installation and maintenance of cable lines become more stringent, the demand for the appropriate tools and special devices is actively growing. And we are talking, in particular, about such fixing devices as cable ties. Today there is a fairly wide list of types of such products.

At the same time, different categories of these screeds differ from each other in the material of manufacture, design and functionality. Taking into account the performance characteristics, steel, plastic and nylon clamping clamps are widely used not only for their intended purpose, that is, when installing cables.

general description

Regardless of the variety and design features, all cable ties are universal fasteners. Nowadays, they are used in a variety of areas when you need to quickly and securely fasten (pull) something. And above all, we are talking about the performance of professional electrical work, including:

- fixation of cable lines;

- fastening individual sections of highways to the wall;

- banding and grounding of armor;

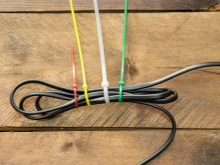

- marking of conductors (ties of different colors and with numbering).

In addition to their direct purpose, these steel and plastic clamps are used by various specialists and even in everyday life. It is noteworthy that the very concept of the fastening devices under consideration was at one time prompted to their creator by nature itself. And the main task at the same time was to create a kind of loop with a reliable lock. Moreover, the latter had to perform two important functions in parallel. The lock is a latch, as well as a regulator of the size of the loop itself.

One of the key points was simplicity of the product, which would make it possible to reduce as much time as possible when performing installation work of any complexity. In parallel with this, attention was focused on such not unimportant factors as the minimum cost of clamping clamps against the background of increased strength. On the way to the set goals, the developer, taking into account all the nuances, repeatedly adjusted the production process, as well as the criteria for the selection of raw materials.

As a result, we managed to find the optimal balance of all characteristics and the financial side of the issue. And the result of long and hard work was the appearance of the first cable tie more than half a century ago. And at that time it was about a strip with a lock, with the help of which the fixing loop was formed. Its main performance indicators were resistance to significant static loads, as well as the ability to withstand the action of a breaking force.

It is worth noting that during its rather long history, the devices in question have changed markedly.... It means that the screeds in their original form have undergone a whole series of modernizations, improvements and all kinds of additions. Thanks to this evolution and the expansion of the list of varieties of the fasteners under consideration, they are currently successfully used by representatives of various spheres and industries.

Ties have become indispensable helpers and are actively used from electricians laying cable lines to housewives, gardeners and truck farmers.

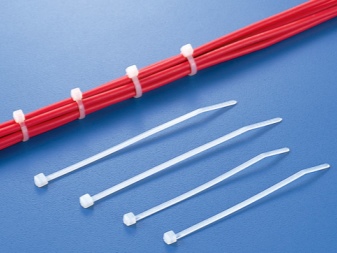

Now the most common and, therefore, the most recognizable is a device in the form of a tape made of plastic and having a lock, as well as notches for fixing a certain diameter of the loop. But it must be borne in mind that this classic, in fact, type of fastener is variable. So, when choosing such clamping clamps, it is important to pay attention to the following key points.

- Length and width of the tape.

- Features of the locking unit. It can be with or without reverse. Depending on this feature, clamps are divided into disposable and reusable.

- The presence of notches on both the inner and outer sides of the tape.

- The ability to withstand exposure to ultraviolet rays.

- Susceptibility to low temperatures. For outdoor work, frost-resistant screeds are produced.

Predictably, the size of the clamp directly depends on how large and heavy an object it can fix with it. The described fasteners are manufactured taking into account the standards of the current GOST. So today screeds with the following standard sizes are on sale.

- Length - 80, 100, 150, 200, 250, 370, 550, 750, as well as 1020 and 1200 mm.

- Width - 2.5, 3.8, 4.7, 6.2, 7, 9, 10 and 12 mm.

- Coverage (maximum rate) - 16, 24, 33, 51, 82, 118, 222, 300 and 400 mm.

It is recommended to pay special attention to the presence of notches for the lock on the inner side of the clamp. It is important to take into account that they can damage the conductor or any other fixed element if vibrations are present. In the context of UV resistance, there are three groups of screeds that can be characterized by their color. So there are white, that is, unpainted, black and colored versions.

Views

Now manufacturers of modern fasteners offer potential consumers more than a wide range of products. The catalogs of such companies contain products from various materials, including stainless steel. Also, the models of clamping clamps differ from each other in terms of design and purpose. In addition, the list of criteria for classification includes the resistance of adaptations to the negative effects of environmental factors among and, in particular, temperature fluctuations. Naturally, each of the varieties of products for fasteners has both clear competitive advantages and no less significant disadvantages.

First of all, it is worth focusing on the size of the cable ties, which directly determines what kind of load the fasteners can withstand. By the way, in some cases, the clamps are connected to each other, thus increasing their length, and, consequently, the maximum diameter of the fixing loop. An equally important role is played by the width of the strips, which determines their strength. It is important to understand that there are special requirements for fasteners used in an aggressive environment. Do not forget about fire safety. Based on this, it is important that the clamps used when laying cable lines do not support combustion.

Equally significant will be the increased resistance to vibration, moisture and chemicals.

By construction type

One of the important parameters is the design features of modern screeds.... As already noted, over more than half a century of history, the original appearance and structure of this fastener has changed significantly. Now on the market there is a wide selection of types of clamping clamps that can satisfy the needs of any potential buyer. In this case, we are talking about the following versions.

- Heat resistantmade of nylon, which is resistant to high temperatures for a long time. Such screeds are capable of withstanding up to 120 degrees.

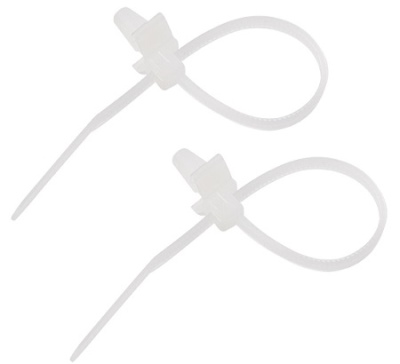

- With mounting holedesigned for installing the clamp itself on various, mostly smooth surfaces using self-tapping screws, rivets or screws.

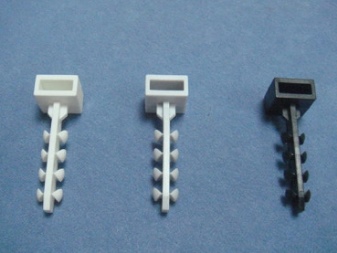

- With anchoring fastener, which is also known as "dowel-piston". Such models allow you to lay cables and wires with their fixing on metal surfaces, the thickness of which does not exceed 2 mm.

- Reinforced structures. The principle of the screed in this case will be classic, but it is worth highlighting the structural differences. This refers to a retainer made of stainless steel, as well as the absence of notches (teeth) on the tape.

- Clamps equipped with a double locking knot... Such devices, as a rule, are made of nylon 12 - a material characterized primarily by high strength and resistance to aggressive environments. In particular, the double lock ensures maximum reliability of the clamp fixation in the working position, regardless of the temperature conditions and other operating conditions of the fasteners.

- Models with a dowel or a platform for it. In the first case, the main distinguishing feature is a split lock, thanks to which it is possible to release the held wires or, conversely, add new ones. In addition, the dowel itself greatly simplifies the reliable installation of the screed. The second option provides for the presence of a dowel in the kit, onto which the mentioned platform is screwed. This allows you to quickly and comfortably lay cable lines and wires on wood, as well as concrete and brick surfaces, without the need for self-tapping screws.

- Reusable ball-type couplers are reusable devices. Their main feature is that they consist of a tape in the form of a chain of small spherical elements and a lock of the corresponding configuration.

- Ball Clamps with Nameplates - This is a model similar to the previous one, but differs from it in the presence of a special area designed for marking fixed objects (cables).

- Couplers equipped with a horizontal type lock. Such modifications of fasteners are often used for banding. Their key advantage is the ability to add wires to the harness and remove its constituents.

- Clamps with a lever for opening the lock, which greatly simplifies the operation of the device after its installation.

In addition to all of the above, it is also worth paying attention to screeds with mounting pads. This refers to a variety of fixtures used to secure cable lines to smooth surfaces. For this, platforms with a self-adhesive element are used.

It should be noted that in this case, installation is also provided with self-tapping screws and screws, for which there are special holes in the platforms.

By appointment

Taking into account the characteristics, as well as the operating conditions, the described fasteners can be divided into two large groups - these are screeds for internal and external work. Taking into account the fact that street clamps are much more often and more actively exposed to the action of an aggressive environment, appropriate materials and additives are used for their manufacture. Thanks to these components, the screeds become as stable as possible in front of:

- direct rays of ultraviolet radiation;

- high humidity;

- sharp temperature fluctuations;

- low temperatures (special frost-resistant models).

As practice shows, the sun's rays have the most noticeable effect on fasteners. In order to neutralize the negative effect in the production of screeds for outdoor installation, coal powder is used as an additive. This component acts as an effective stabilizer and gives the products a black color. However, it is important to remember that not all black clamping clamps are characterized by increased resistance to difficult weather conditions.The point is that internal ties can be of any color, and street ties are exclusively black.

It is worth focusing on the variety of colors of the tie hinges in the context of their purpose.... The fact is that such a wide range allows for expressive and maximum noticeable marking of wire bundles.

At the same time, taking into account a number of factors, multi-colored clamps will help to visually make the wiring almost invisible.

In addition to everything already stated, analyzing the existing types of screeds, it should be noted that they are divided into two more categories: intended for single use and reusable. Predictably, in the second case, the locking mechanisms can be opened, or the clamps themselves have a so-called reverse stroke. In practice, disposable models are most relevant in cases where you need to quickly and reliably fix a bundle of cables (wires) or any other items. However, in such cases, it is important to remember that it will not be possible to dismantle the fasteners without cutting the tape.

This disadvantage of disposable fasteners is fully compensated by their low cost. At the same time, if it is necessary to articulate several ties to increase the girth, such clamps will provide an extremely reliable connection and subsequent fixation during installation. Comparing all the pros and cons, as well as taking into account the value for money, we can confidently state that the use of disposable screeds is economically justified.

Materials (edit)

First of all, you should pay attention to the metal fasteners. They are usually used in cases where there are increased loads, as well as unfavorable climatic and weather conditions. In addition, we can talk about an aggressive environment and, in particular, the possibility of exposure to chemicals. These screeds are made from low carbon steel as well as ship steel. One of the important components of alloys in this case will be molybdenum, which greatly increases the anti-corrosion properties. By the way, similar functions are performed by the PVC coating of the clamps.

The list of clear advantages of steel models includes the following.

- Increased resistance to external influences and the ability to use in the harshest conditions.

- Good performance.

- Resistant to UV rays.

- Increased tensile and tensile strength.

- Durability.

- Anti-corrosive properties, allowing the clamps to be installed even in seawater.

Despite such a compelling list of clear advantages, it is worth noting that metal ties are not suitable for all cases. Another important point is the relatively high cost of products. In conclusion, it should be recalled that for the installation of such clamping clamps, as a rule, a special tool is required.

Modern plastic products are made of polyethylene or polyamide and nylon. Compared to the metal options, they are much lighter, more compact and of course cheaper. In addition, we are talking about ease of installation and minimizing the risk of damage to the conductor. On the other hand, plastic is not able to withstand heavy loads and, in some cases, is less resistant to aggressive conditions.

Standard clamps belonging to the described category retain their key properties at temperatures ranging from -40 to +80 degrees.

Particular attention should be paid to fasteners made of polyamide 6.6 and polyamide 12. In the first case, it is important to highlight the following key characteristics of screeds.

- Working temperature - from -40 to +85 degrees.

- The temperature at which the installation is carried out is from -10 to +60 degrees.

- The short-term heating threshold is +110 degrees.

- Screed melting - from 256 degrees.

- The moisture absorption indicator is 2.7% at a humidity of 50%.

- The declared performance properties are relevant for 3 years.

In the situation with products made of polyamide 12, the following parameters will be discussed.

- Operating temperature - from -45 to 85 degrees.

- Installation temperature - from -30 to +60.

- Short-term heating - permissible up to 120 degrees.

- Melting temperature - 186 degrees.

How to use it correctly?

A classic coupler has projections in the form of teeth (notches) on one side, and a lock on the other. In the process of fixing bundles of wires and any other objects, it is enough just to pass the tape through the locking element and tighten. In situations with disposable retaining straps, they can only be removed by cutting. Given their low cost, their use is more than justified.

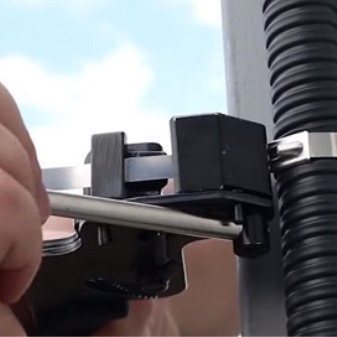

The described loops can be tightened either manually or using a special tool resembling a pistol... In such situations, there is not only a tension on the tape, but also an automatic trimming of the ends in the immediate vicinity of the locks. One of the indisputable advantages of such devices is that there is the possibility of regulating the effort.

The use of a specialized tool allows you to maximize the speed of work of any complexity, as well as improve its quality.

Considering the feasibility of using these mechanical, manual devices (pistols), the following key points should be taken into account.

- Maximum ease of use when fixing both single cables and wires, and large bundles.

- Sufficiently wide range of adjustable force.

- Good quality of tightening and fixing the buttonhole.

- Easy and precise trimming of excess tape.

- Minimization of manual labor.

- Increased productivity.

When using the considered clamping clamps, it is necessary to remember the main factors that can have an extremely negative effect on their service life.

- Temperature conditions. In particular, nylon loses strength when the thermometer is raised above +85 degrees Celsius. At the same time, the elasticity of the material is significantly increased. At the same time, in the cold, such clamps become very fragile and can simply break.

- High humidity, reflected in the main characteristics of many screeds.

- Prolonged exposure to direct and intense rays ultraviolet.

- Thickness the tape itself.

In addition to all of the above, it is not worth taking off the account and such an indicator as the load on the screed. Limit values are relevant for each type of retainers, which are strongly discouraged from exceeding.

An equally important point is the negative impact of aggressive substances. The latter, in particular, include acids and their vapors.

The comment was sent successfully.