Features of roofing nails

Roofing nails are used to attach waterproofing materials to the roof structure. Roofing materials can be flexible and plastic, produced by manufacturers in a roll format. The tensile strength of such materials is quite low, so their installation must be done carefully, using special hardware that does not destroy soft roofing material or roofing felt. Since the nails were used to fasten the roofing felts, hence their name came from - roofing felts. Let's consider in more detail the features of roofing nails.

What is it and what is it for?

The technical characteristics by which roofing nails are made comply with GOST standards. But these standards also allow some deviations from the prescribed execution regulations, namely:

- small errors in the diameter of the products are allowed, the parameters of which depend on the length of the nail;

- the deviation along the length of the nail cannot exceed the indicator of its diameter;

- the central position of the axis of the rod relative to the cap should not exceed standard norms, for example, for hardware 3–4 mm, the deviation of the axis can reach 0.4–0.5 mm;

- the surface of the outer side of the head of the nail should be even and flat;

- the sharpening of the tip of the working rod of the hardware should not exceed an angle of 40 °;

- a certain degree of deflection of the nail rod is allowed, depending on its diameter, for example, for hardware with a diameter of 90 mm, the deflection should not exceed 0.5–0.7 mm.

At the manufacturing plant, a finished batch of hardware is tested in laboratory conditions for compliance with tolerances of deviations from GOST, the flatness of the head, the central position and the deflection of the rod are analyzed. As for the shape of the cap and its smoothness, as well as the height - these parameters are not subject to research in the factory laboratory. Hardware intended for roofing work depends on the materials with which they interact. Roofing can be smooth or wavy. Shingles, roofing felt, bitumen-coated membranes are considered smooth materials. Corrugated material is a corrugated type of roofing slate made of asbestos cement.

The performance characteristics of roofing nails are as follows:

- the nail shank does not have a thread, it is sharpened and its standard length is from 20 to 40 mm;

- the head of the nail is round, flat and smooth, its diameter is proportional to the diameter of the nail and is its size multiplied by a factor of 2.5;

- the height of the head cannot be higher than ¼ of the shank diameter.

The similar structure of this hardware makes it possible to use it for fastening a soft roof without fear that the material will be perforated or damaged. The wide flat head of the nail holds the layer of material securely when it acts as a pitched surface.

Other nails, under this load, would simply tear the roof sheathing.

The use of roofing hardware today is very diverse, namely:

- fixing soft roofing materials on the roof surface;

- reliable fixation of asbestos-cement plates;

- for the assembly of component parts of cabinet furniture;

- when joining chipboard or plywood sheets that do not have an upper protective layer.

The use of roofing hardware is advisable only if when the thickness and density of the material are small. For this reason, these hardware cannot be suitable for finishing because of their large hat.

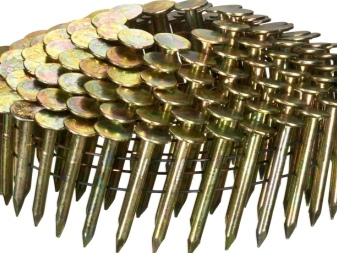

Species overview

The design of roofing nails is simple, but the classification of hardware is not too diverse, since these products, intended as fasteners for roofing material, have a very specific application.

- Galvanized nails are made of low carbon steel wire... After cold stamping, the nails are coated with a thin layer of zinc. The thickness of the coating does not exceed 6 microns, but this layer protects the hardware from the effects of a humid environment and prevents the development of corrosive processes. Galvanized nails with flat round heads can be safely used for outdoor use. Zinc provides the hardware with durability, the fastener made will be strong and reliable for many years.

- Uncoated nails are regular black nails made from steel wire... Since the hardware does not have a zinc coating, their cost is much lower than that of galvanized counterparts. But such hardware quickly rusts and spoils the appearance of the roof with rust stains. Therefore, it is advisable to use black nails for internal work in order to assemble furniture or when assembling chipboard joints.

- The ugly surface of the rod - this is the most common option where the nail stem has no notches or threads.

- Thread on the surface of the rod - this type of hardware is used in areas with difficult climatic conditions, where strong winds constantly blow. The thread on such products is made in the form of knurling and during installation. It provides a strong connection between the roofing material and the roof structure.

Important! The listed types of roofing roofing nails can be distinguished from each other by their appearance. Galvanized hardware has a silvery light shade, while uncoated nails are dark gray.

Dimensions and weight

Roofing roofing hardware has 5 standard sizes, which are quite enough to securely fix any soft roof covering. It is noteworthy that the diameter of the head of the nail changes depending on the increase in the length and diameter of the rod. There are two types of nails according to the diameter of the head - A and B. A type A head has the smallest diameter, and a B type head has the largest diameter with equal length and diameter.

Depending on the parameters of the hardware, their weight also changes. It is customary in retail chains to sell nails by weight. To correctly calculate the required number of hardware by weight, you can use the table where the weight is indicated for 1000 pieces. nails.

Diameter, mm | Length, mm | Weight per 1000 pcs. / kg |

3 | 40 | 2,24 |

2,5 | 40 | 1,53 |

2,52 | 32 | 1,23 |

2 | 25 | 0,6 |

2 | 20 | 0,5 |

The minimum size is 2x20 mm. The maximum length of the hardware leg is 40 mm. Higher length parameters, for example 70 mm, would be unsuitable for roofing work, since the thickness of soft materials is insignificant.

Installation features

Roofing nails are widely used, but they are especially in demand during the season of roofing or construction works. For decoration, hardware with a large hat is unsuitable, as it can spoil the appearance of the product. As for the installation of the roof, such hardware is used as follows:

- when choosing the length and diameter of the nail, the thickness of the roofing material must be taken into account; it is impractical to choose the longest nails, since at the time of their hammering with a hammer, the hardware rod can bend, distracting the master for dismantling and replacing the fastener, but the worst thing is that at this moment the surface of the waterproofing roofing material can be damaged;

- the most popular sizes of roofing nails among roofing masters are products with a diameter of 7 mm and a length of 25 mm; to mount the roof on the ridge of the roof or its ribbed lags, it is enough to take a nail 30 mm long with a head diameter of 10 mm.

The installation process of hardware is simple - it is driven into the roof structure until the head fully contacts the roofing material.Hardware should be placed in a strictly vertical position at an angle of 90 ° relative to the structure of the lathing.

The following video will show you how to properly drive nails into a board.

The comment was sent successfully.