All about dowels-nails

When choosing a strong and reliable fastening of a structure to a monolithic surface of a wall, ceiling or floor, dowels are most often used. This type of fastener, in terms of its properties to hold large loads of structures, with the right choice, is compared in terms of reliability with anchor bolts. Dowel fasteners are produced today in various modifications and have different parameters in terms of diameter and length. Focusing on the type of dowel-nail, the methods of its installation are also different.

What is it and what is it for?

Dowel fastening is a way of mounting various objects or structures to solid solid surfaces - this is its purpose. It works great on concrete, brick or stone surfaces, and can also be applied to drywall and ceramics. Externally, the dowel-nail looks like a device that combines 2 components: a dowel structure made of plastic and a screw. The construct of certain varieties of the dowel frame has a limiter made in the form of a cuff, which is necessary so that when the dowel is driven into the wall, the device does not sink into the prepared hole. The limiter can be of various modifications - round, in the form of a cylinder or a countersunk type.

It is possible to install dowel fasteners inside the wall using a hammer, while the installation process is simple and does not take much time. This mounting option is used for mounting drywall systems, for installing a plinth or cable channel, hanging shelves, cabinets and much more. The dowel-nail performs reliable fastening only in solid monolithic structures; it is inappropriate to use it for aerated concrete or hollow bricks.

This is explained by the fact that the dowel-nail does not have such a spacer component that would help it to gain a foothold in the loose material.

Specifications

The quality of the dowel fasteners is regulated by GOST standards, but during its manufacture, this regulation allows a change in some technical parameters. For example, it is possible to change the diameter, structure, length or weight of this product. Despite such tolerances, there are standards that must be strictly followed by each manufacturer.

- The dowel-nail is produced from a steel rod, the type of alloy of which is resistant to mechanical stress. Rockwell hardness of the material is at least 54-56 HRC.

- Curvature is allowed at the screw body shank. Normally, if the shank of the screw is less than 50 mm, the curvature can be 0.1 mm, and if the shank is more than 50 mm, the allowed curvature is up to 0.15 mm.

- The dullness of the sharp tip of the nail can be no higher than 0.8 mm, while the tip of the screw should evenly pass into the body of the rod, without forming cracks, notches or sunsets.

- The presence of traces left by the clamping devices during processing is permissible for a nail on the working surface of the rod. The tip of the product can have several edges.

- If there is a corrugation on the dowel, then the step between the edges will be up to 0.8 mm, and the depth between the edges should not exceed 0.15 mm.

- Some models of the nail dowel have a washer, which is placed quite tightly on the product body, while the shear force of this washer should not be lower than 0.3 kN.

- Fasteners are made with zinc coating, the thickness of which must be at least 6-7 microns.The application of a zinc layer to the surface of the nail is carried out by the cathodic method.

As for other characteristics, their changes can only be carried out in accordance with reasonable and agreed technical regulations.

Species overview

The options for the manufacture of a nail dowel can be with or without a threaded thread, its dowel is made in the form of a plastic body with a secret collar or a cylindrical shape. The nail itself is equipped with a cap, which most often has a mushroom outline. Along the length of the rod, the nail has a spiral thread, and if the nail is driven, then its surface can be smooth, and there is no plastic cylinder in the fastener design. This type is classified as fire resistant, since the metal, in the absence of plastic, does not support combustion. Some models of the dowel are produced with fitted washers. The washer-shaped spacer itself is initially located at the end of the nail body, and during installation it moves towards the head - such fasteners are the most durable to the effects of loads.

Dowels-nails are classified according to the method of installation.

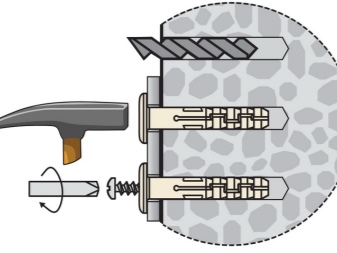

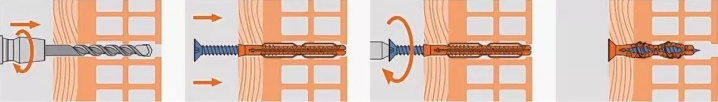

- Installation using a conventional hammer - this method is manual. The body of the nail is threaded - then it is screwed in using a screwdriver, or with a smooth working part - then it is hammered in with a hammer. A threaded nail, if necessary, can subsequently be unscrewed and dismantled, and it is very difficult to dismantle a product without a thread, sometimes it is simply impossible.

- Installation using a construction and assembly gun - in this case, the structure of the nail is distinguished by the presence of a special cuff, but it does not have a plastic expansion cylinder. Such a product allows for quick installation and can withstand heavy loads.

There are many types of fasteners according to the material of application.

- For aerated concrete walls - the design of the dowel is equipped with ribs in the form of spirals, which wedge at the moment the fasteners are driven into the prepared hole.

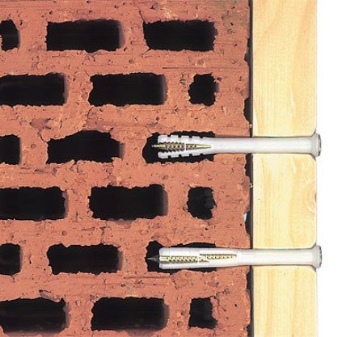

- For masonry or concrete monolith - nylon dowels are used for working with concrete or brick, they can withstand up to 450 kg of load. These models can have dowels with or without a thread, the diameter is in the range of 2-16 mm.

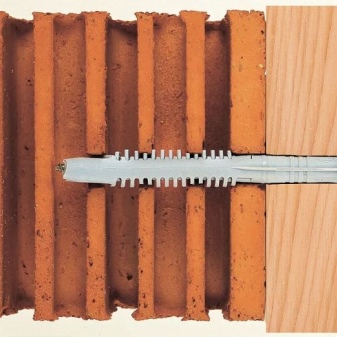

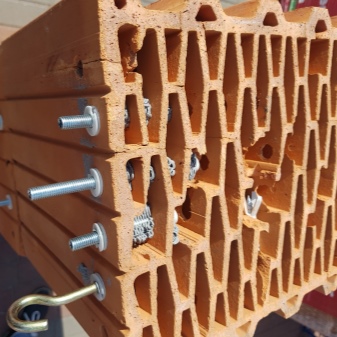

- For slotted with voids or solid mass - such fasteners have a great length, which is 60-360 mm. The design of the spacer element at the dowel is made in such a way that, when it enters the hollow base, the nail dowel can hook several bridges inside the material, thereby providing a strong hitch.

- For lathing - such dowels are called distance dowels, and they make it possible to fix the structure of the lathing with a small indent from the wall surface. This distance ranges from 1-30 mm. The dowel is divided into 2 parts, one of which is intended for the structure rail, and the other for the wall. Both parts are connected with a screw.

With this method, it is possible to achieve compensation for wall irregularities and obtain an even fixing of the structure.

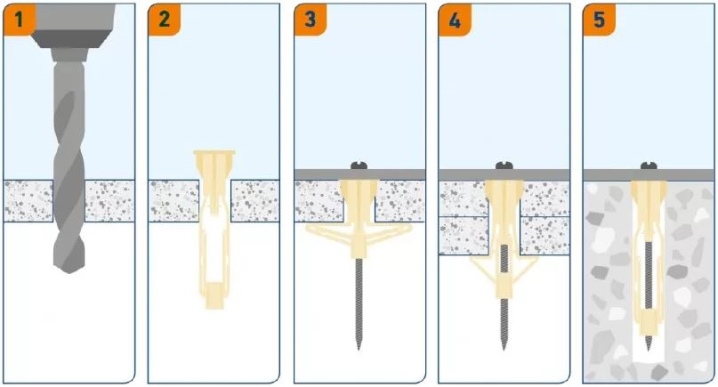

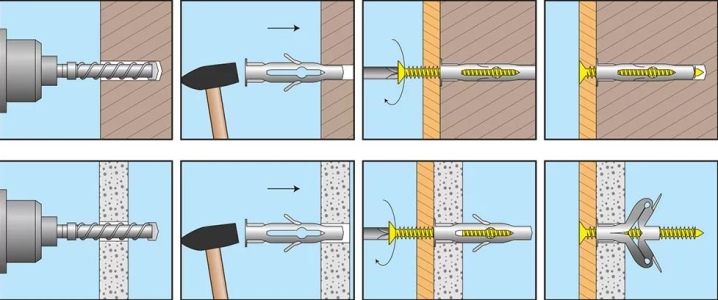

- Universal fasteners - its device is capable of self-determination inside the surface during installation. If the fixation occurred in a dense material, then the dowel body expands, and if the installation is carried out in a hollow material, then when it enters the void area, the structure protrudes and adjoins the support.

- For thin surfaces - for this purpose, dowel structures made of metal are used. When mounting a steel nail, the metal frame swells and adheres firmly to the area of the thin walls of the material.

- For rack and pinion guides, floor plinth, wall lathing - a nail type of dowel is used. It is indispensable in cases where multiple mounting of fasteners is required. The fastening nail of such a device is equipped with a special knurling.During the installation process, the working part of the screw is inserted together with the dowel into the prepared hole through the crate or rail, and then this pair is hammered in with a hammer.

After completing the fastener, it will not be possible to dismantle it if necessary.

- For suspended ceiling structures - a special fastener is used, called a "butterfly", which works on a surface that has voids. When mounted, passing the first dense level of material, under the action of a spring mechanism, the dowel opens its system, thereby resting on the sheathing structure from the inside. The butterfly dowel is provided with hook-shaped protrusions and has a thread.

- For heavy hanging products - the structure of the dowel is used for working with concrete and brick surfaces in situations requiring heavy gates or other products to be fixed on the working surface. Such anchor dowel fasteners will be able to withstand a multi-ton load.

- For aerated concrete and gypsum board - both nylon and metal types are produced, which have the tip of the working part in the form of a drill, and there is also a thread on the rod of their body. These dowel fittings do not require drilling holes. For example, when you need to fix the acoustic material, the entire structure is screwed in with a screwdriver or screwdriver.

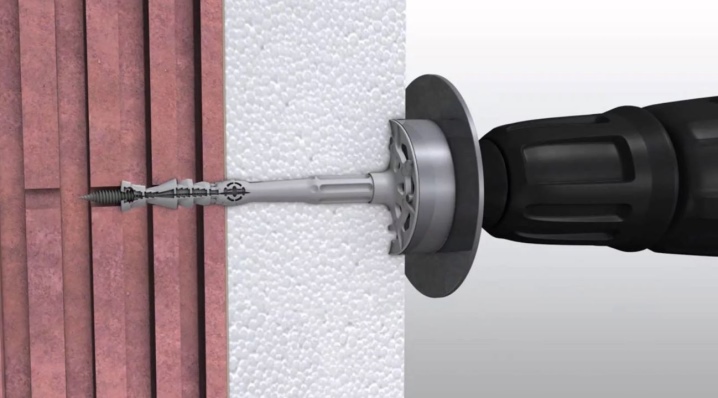

- For hardened concrete or for fixing thermal insulation - for the use of a dowel, holes in the material are not previously made, and the fasteners themselves are hammered without a nail.

- For bricks with slotted voids - the injection type of dowel fasteners is used. It works with a mesh anchor inserted into the prepared hole, into which a dowel is then driven in, after which a hardening compound is introduced to it using a syringe device. Under the influence of the adhesive, the anchor mesh is destroyed and a round anchor is formed at this point.

According to the shape of the side or head, the dowel-nail is of 3 types:

- cylindrical;

- with countersunk head type;

- wide mushroom shape.

Various materials for working wall or ceiling surfaces require a thorough approach in the selection of the fastening device. In addition, the size of the dowel-nail itself depends on the type of work performed.

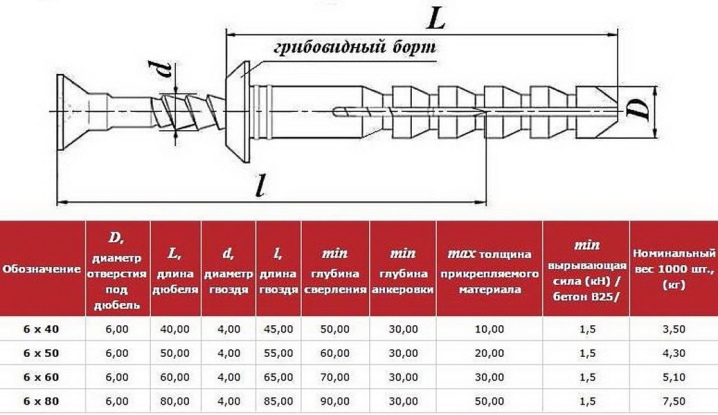

Dimensions and weight

For ease of use, manufacturers produce dowel fasteners in various sizes. The parameters of this product are marked with two numbers. For example, 10 by 80, as well as 30 by 6 or 8 by 160 - the first number in this case shows the size of the diameter in millimeters, and the second number will indicate the length of the dowel. The parameters of the dowel in diameter are in the range from 5 to 23 mm, as for the length, it is in the range from 10 to 160 mm, although there are products with a length of 200 mm, for example, a dowel-nail 10x200 mm.

The most common sizes for household use are fasteners 6x40, 5x50 or 5x60 mm, as well as 6x60 mm. For industrial use, dowels of 8x160 mm are often used. When purchasing a dowel-nail, the consumer is faced with the fact that they are often sold by weight, and the mass of products for wholesale or small-scale purchase is indicated not for 1 unit of fasteners, but for 1000 dowels.

The weight of the product directly depends on its diameter and length, although in many hardware stores the dowel-nail is sold individually or in small batches.

Selection Tips

In order to choose the right dowel-nail, you need to understand what kind of load the fastener has to withstand, and what it will be intended for. Most often, dowel fasteners are used to work with concrete material in the form of a dense monolith. Consider the recommendations of experts for the selection of fasteners.

- If you need to hang kitchen cabinets or other items with a fairly large weight, then you need to stock up on a mount, the length of which will be at least 85 mm.

- When making fasteners for a plinth, for a cable channel, for insulating walls with one or another material, as well as for fixing structures located horizontally, the length of the dowel attachment is chosen from 30 mm, and its diameter is taken from 6 to 10 mm.

- For the installation of a suspended ceiling, as well as for PVC structures or the installation of lighting devices - in a word, for those products where the load comes from the lower part of the structure, dowel mounts are used, which have spacer antennae or notches applied to the working case.

- If you need to choose a dowel fastener for a ready-made hole in the material, then it should be remembered that the size of the diameter of the hole and the dowel fastener must be equal. In the case when the hole diameter is larger than that of the dowel, high-quality and reliable fasteners will not work, since the dowel will loosen and come out over time.

- In walls made of foam concrete, the dowel fastening can become a kind of softening cushioning material. In this case, it is necessary that such fasteners be tightly fixed in the material, and the weight load of the supported structure is evenly distributed over all fastening nodes, that is, over the rest of the dowels.

Experienced installers believe that it is best to use a universal type of fastening for an old concrete wall, since unfilled voids can unexpectedly be found in a concrete monolith. As for the size and diameter of the dowel-nail, the more the load is implied on it, the thicker and longer the fasteners should be.

Mounting features

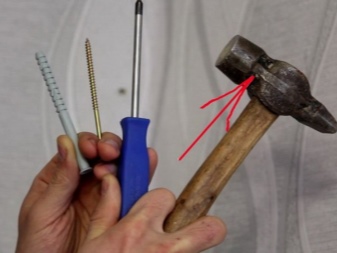

It is quite simple to use fasteners in the form of a dowel-nail with minimal skills in working with an electric drill and a hammer. It is quite possible to install fasteners for household needs on your own, without inviting hired craftsmen to perform these works. Before you start fixing, you need to calculate the number of dowels, their diameter and size. To complete the work, you will need to use a hammer, an electric drill with a victorious drill or a perforator with a drill, and you also need to prepare the selected number of dowels-nails. To use the fasteners correctly, you need to know whether the dowel fasteners will have to be tightened, or they will need to be hammered.

For different materials, the features of fixing the dowel will be different.

On a brick

A hole is made in the intended section of the wall surface, and, in order to avoid the formation of cracks in the body of the brick, they begin to drill at low speeds of the drill, gradually increasing them, but only when the depth of the hole reaches 8-10 mm. Before installing the dowel, dust and small brick chips are removed from the hole, and then the dowel is driven in with a hammer.

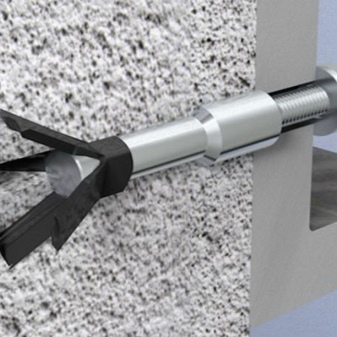

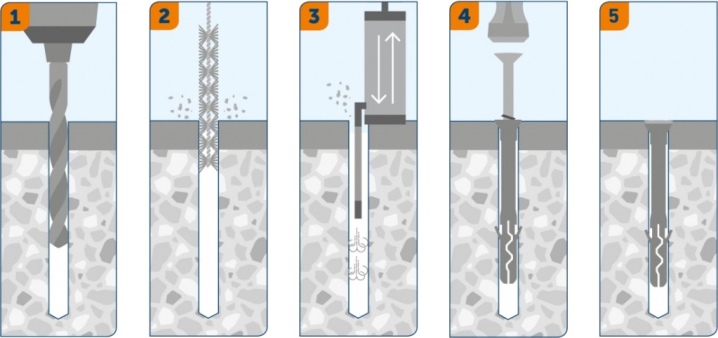

On concrete

The area for the hole is marked with a center punch, after which they take a perforator and drill the hole to the required depth. The diameter of the drill or drill bit for drilling is required to be taken equal to the diameter of the dowel fastener. As for the length of the hole, it is made 5-6 mm longer than the dowel you have chosen. Further, dust and fragments of material are removed from the hole using a household vacuum cleaner. Then the dowel is hammered into the hole with a hammer, and the screw itself is screwed in or hammered into the dowel structure. When hammering in a screw, you need to leave 3-5 mm of its free edge of the head in order to suspend the mounted structure.

On drywall

Great care is required from the installer when working with this fragile material. First, a hole of the required length and diameter is made in the drywall, and then the dowel fasteners are inserted all the way, lightly tapping on its head with a hammer, after which it is required to screw the screw into the dowel structure with a screwdriver. When working with plasterboard surfaces, you need to measure the mass of the structure attached to them.

If it is quite large and heavy, then it is not recommended to use a dowel-nail, since this type of fastening will destroy the material under the influence of the weight of the structure attached to them.

On ceramic tiles

During installation work, the ceramic material should be treated with care, as it has increased fragility. A place for drilling a hole is marked on the surface of the tile, then a metal drill is taken and a depression of 0.5 mm is made, that is, a layer of enamel is removed. Next, they take an electric shock drill and drill a hole of the required depth. The structure of the dowel fastener is placed in the hole until it stops and the screw is tightened.

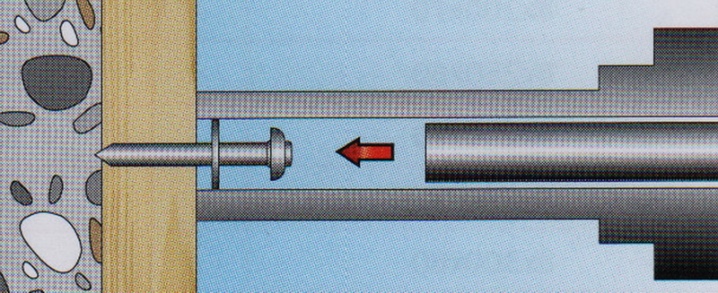

The listed installation methods imply that the dowel-nail will be screwed or hammered into the working hole. But, in addition to these options, there is another way to mount the dowel attachment. To implement it, you will need to take a special construction and assembly gun, with which the structure is "shot" to the working monolithic surface. This is most commonly used for concrete. In the work, they use a special dowel, which is equipped with a special washer, which is responsible for the tight fit of the fasteners in the wall. The construction and assembly gun has a peculiar device that, after pressing the trigger, shoots the dowel into the wall, and this action moves the washer from the end of the dowel fastener to its head, securely fixing the mount in the wall.

For information on how to install the dowel-nail into the wall, see the next video.

The comment was sent successfully.