All about polyurethane primer

Polyurethane is the best material to strengthen concrete, improve its technical performance and refine it. One-component impregnations based on it are used by masters to increase moisture resistance and strength. But the concrete surface must be protected from the negative effects of the external environment, and this requires a suitable primer mixture. In this case, it will be appropriate to use a polyurethane primer.

Advantages and disadvantages

Thanks to the primer, the concrete acquires a flawless surface, in addition, the mixture helps to make adhesion with subsequent decorative coatings - varnish, paints, enamels - more reliable.

Primers based on polyurethane are considered the best for priming because they have many advantages over other formulations.

- Polyurethane primer combines well with any substrates that have a porous structure with high absorbency. Therefore, it is used not only for priming concrete, but also for surfaces made of wood, metal, brick.

- Polyurethane can be used on floors with heating switched on.

- This material is not a hindrance, even if there are dust-like particles on the base. The primer can be applied to a slightly cleaned surface, and dust particles will be bound during the curing process.

- One of the important positive qualities of the primer is the possibility of interior and exterior finishing.

- When compared with compounds of the same purpose, polyurethane is a more economical material. Of course, the consumption depends on the depth to which it penetrates into the thickness of the product, but in any case, by 1 square meter. m of surface is spent from 200 to 500 grams of polyurethane mixture, and other compounds - 2-3 times more.

It can be added that due to the application of polyurethane primer, different structures become stronger, show high impact resistance, moisture resistance, excellent adhesion with the finishing lining.

The primer mix has small drawbacks, but they are not so critical:

- the drying time for most of these compositions is 2 hours, and polyurethane will take from 3 to 5 hours to cure;

- the application procedure is carried out manually, since there is no way to use a spray;

- polyurethane has a relatively high price (but we must not forget that the coating is distinguished by good wear resistance and durability, and a long service life is quite worth the money).

Views

According to the degree of solidification and purpose, all soils are divided into two main groups.

One-component mixture

Includes directly polymer and solvent. The composition has a fluid elastic consistency, which allows it to be used for processing concrete, wood and fibreboard. Due to the structure of the mixture, deep penetration of the soil into these materials is achieved, optimal leveling and reliable adhesion to the final finish in the future.

Two-component primer

It is produced in the form of two separate components - hardener and primer mixture - in different containers. They are mixed before use. But this variety is not so plastic, although it has greater strength. True, this does not prevent it from being used for concrete floors designed for significant loads. Two-component compositions are not used for MDF and wood, but they are suitable for metal, since they contain zinc, which protects the material from corrosion. For basements, hangars and garages, such a subtype of primer as primer-enamel, which replaces staining, is relevant.

Other types of polyurethane-based primers also have valuable properties and features. Let's list them.

- Alkyd primers. They are in demand for woodworking in street conditions. They prevent discoloration of wood, its darkening, and can be used as a topcoat if it is a primer enamel.

- Adhesives. They roughen the surface layer for good adhesion to polished concrete substrates.

- Acrylic primers. They are used for processing wood and concrete, provide deep filling of the porous structure, promote leveling.

- Epoxy enamels, paints and primers. Strengthens concrete and metal, and also creates a protective layer on their surface.

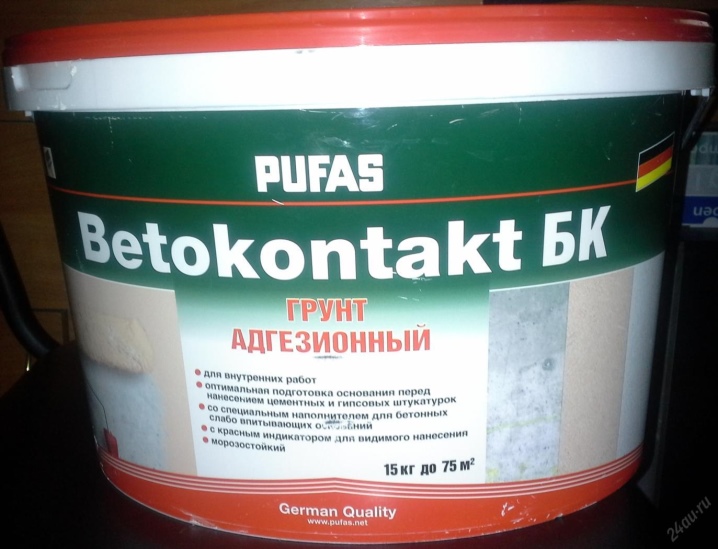

- Before installing drywall or tile panels, it is best to cover the concrete base with a special primer called concrete contact.

The most popular are the following polyurethane based primers.

- "Ground 1101" - one-component product with the inclusion of an organic solvent. It is applied on concrete, wood, plaster, significantly increases moisture resistance, wear resistance and adhesion to the finishing material. The composition of the product is safe for human health, easy to apply.

- Primer-primer "Primer PU 01" - a universal mixture, suitable for any substrates, well dedusting the surface of structures, increases their strength, dries quickly.

Any priming agents are classified into conventional and deep penetration formulations.

Applications

Polyurethane primer can be used wherever concrete, metal, wood, brick and other materials are used, requiring alignment and staining with paint and varnish products.

- The polyurethane-based primer is ideal for the treatment of floors and walls in residential and industrial buildings. Especially where subsequent painting, plasterboard or tile laying is foreseen.

- Polyurethane compounds are used to increase the life of the facades of houses, including wooden structures, as well as wall and floor bases made of wood.

- The primer is successfully used to treat MDF furniture boards before polishing and painting them.

- The mixture is used to strengthen concrete floors in public buildings with high material loads.

- In production workshops, soil is necessary for concrete in order to exclude unwanted dusting on its surface. In addition, polyurethane serves as a finishing coat.

With the help of a metal primer, you can repair or protect products made of galvanized, ferrous metal, aluminum and steel, minimize the threat of rust on any metal structures inside and outside the room.

How to choose?

The correct choice of primer is the key to successful leveling, high adhesion and maximum protection for any structure. When buying primers, you should adhere to a number of requirements for the mixture.

- The type of material to be primed must be taken into account. Some varieties are designed specifically for MDF, metal or concrete.

- For residential premises, you need to choose only safe products that do not contain toxic additives that can emit harmful fumes. Acrylic and polyurethane products are most suitable for this.

- Depending on where the structure to be treated is located (inside the house or outdoors), you can select conventional primers or mixtures for outdoor work.

- Any high-quality soil should contain fungicidal and antibacterial components.If it is necessary to make a coating on metal, then anti-corrosion protection is important, that is, the primer must include zinc-rich components.

Professionals recommend purchasing only fresh primers from reputable manufacturers. In this case, the possibility of high-quality reconstruction or creation of a new coating on surfaces from different materials is provided.

See below for testing polyurethane primer.

The comment was sent successfully.