The subtleties of the process of applying concrete contact to walls

Often in the process of construction or repair, it becomes necessary to glue two materials that cannot adhere to each other. Until recently, this was an almost insoluble problem for builders and decorators. However, these days, such tasks can be solved using a special primer called concrete contact.

Specifications

Concrete contact consists of:

- sand;

- cement;

- acrylate dispersion;

- special fillers and additives.

The main characteristics of the concrete contact:

- used for non-absorbent surfaces as an adhesive bridge;

- designed to strengthen the surface;

- consists of safe substances;

- does not have an unpleasant, pungent or chemical odor;

- forms a waterproof film;

- prevents the development of mold and mildew;

- for control during application, a dye is added to the concrete contact;

- sold as a solution or ready-to-use;

- dries from 1 to 4 hours;

- the diluted composition of the concrete contact does not lose its properties within a year.

Suitable for the following surfaces:

- brick;

- concrete;

- drywall;

- tile;

- gypsum;

- wooden walls;

- metal surfaces

Some experts note that the composition does not fit well on bituminous mastic, so it is better not to use a solution with it.

What is it used for?

Concrete contact is a type of sand-cement-based primer with a large amount of polymer additives. The main task of this material is to increase adhesion (adhesion of surfaces to each other). In a few minutes, you can increase the adhesion of any material to the wall. To do this, you only need to apply concrete contact.

It is very difficult to apply plaster on a completely flat wall - it will flake off and then fall to the floor. After processing with concrete contact, the wall becomes slightly rough. Any finish will easily fit on such a basis.

How to prepare the mixture?

Often there is no need to prepare this mixture - manufacturers are ready to sell a completely ready-made solution. When buying such a concrete contact, it is enough to stir the entire contents until smooth. It must be remembered that it can only be stored at freezing temperatures.

Nowadays, few people prepare such mixtures with their own hands, because you need to know exactly the proportions, buy all the necessary materials, and also properly dilute them with water. Then you need to wait and watch how the solution thickens. This is extremely energy-intensive, so everyone buys a ready-made concrete contact. You just need to read the instructions for use and work correctly with this composition.

Application process

Before applying, you need to know:

- concrete contact can only be applied at positive temperatures;

- relative humidity should not exceed 75%;

- you can apply anything to the solution only after 12 - 15 hours;

- it is necessary to properly prepare the surface.

In the presence of dust, the quality of the concrete contact will noticeably decrease. Painted walls should take a long time to finish. You can also use detergents.

It is impossible to reduce the consumption of the solution - this can lead to the formation of places with low adhesion on the wall.

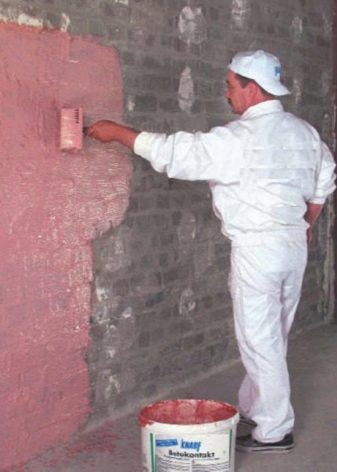

After preparing the surface, you can start the main work:

- it is necessary to remove the old coating. It is best to use brushes for this job;

- the solution must be prepared only according to the instructions;

- this mixture cannot be diluted with water, otherwise the entire product will become unusable;

- the solution must be applied with an ordinary roller or brush;

- when the material dries, it is necessary to apply a second layer;

- after applying the second layer, it is necessary to wait a day to continue finishing work.

With the help of concrete contact, walls can be prepared for further finishing. The main thing is to use the solution correctly and not dilute it to increase the volume.

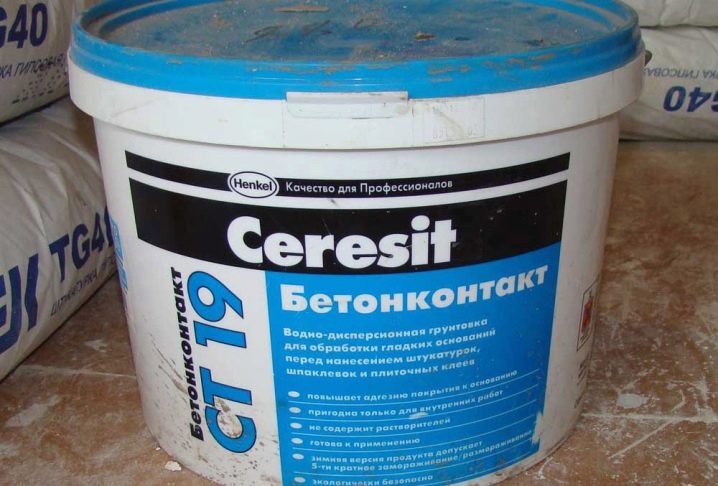

How to apply Ceresit CT 19 concrete contact, see the video below.

The comment was sent successfully.