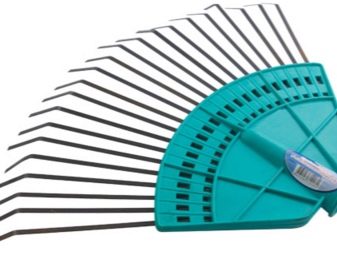

Plastic fan rake: pros, cons and varieties

Proper care of the backyard is impossible without properly selected garden tools. Therefore, in order to maintain the cleanliness and tidiness of the farm all year round, it is worth considering the pros, cons and varieties of plastic fan rakes.

Peculiarities

Traditionally, the rake is used for a wide range of daily tasks of the gardener, namely:

- cleaning garbage from the site;

- collecting fallen leaves;

- weeding;

- loosening the topsoil;

- aerating and leveling the soil;

- collection of cut grass.

Soviet summer residents mainly had access to metal models of this tool in the standard comb form factor, while plastic products were found for a long time only in sets of children's toys. It was only in the early nineties that the first models of this product began to appear with teeth made of various plastics.

The fan shape of the tip allows the tool to cover a wider area, therefore with such a rake it is more convenient to remove from the site relatively light debris evenly distributed over the surface - for example, dry leaves or freshly cut grass... At the same time, the accuracy and developed force of tools with a fan-shaped nozzle is lower than that of more familiar combs.

The fan-shaped version of the product can already be considered not as a universal garden tool, but as a specialized cleaning tool.

Outwardly, such a rake looks like a wide panicle, in which the lower part is made of plastic. The tips of the tines are curved to ensure that the debris you pick up engages.

Views

Unlike tools with a metal working part, which are divided into plate and wire, the plastic version is available only with a plate working part.

At the same time, on sale there are both options with conventional plates, intended exclusively for cleaning, and reinforced models, which, due to the presence of a reinforcing compensator, can also be used for operations for the care of soft soil (for example, surface loosening).

Classic models with a metal working part, are always designed to use a standard 24 mm diameter wood shank.

Plastic models can be equipped with a wooden or plastic handle.and also available without a handle. The standard length of the handle for such equipment is 1.3 m.Options with a shortened handle of 1.2 m, as well as extended ones up to 1.5 and 1.8 m, are also available for sale.Some models are equipped with a telescopic handle, which allows you to adjust the length of the handle for the growth of the user.

The standard span of the working part is 500 mm, and the number of teeth is from 20 to 25.

Other common formats:

- 200 mm, the number of teeth in such a rake is usually 15;

- 520 mm with 25 teeth;

- 560 mm with 22 teeth;

- 580x340 mm, usually products larger than this format have 26 teeth;

- 610 mmBoth 26 and 30 prongs are available;

- 660 mm;

- 820 mm.

Unfortunately, unlike metal versions, plastic models with an adjustable width of the working part have not yet become widespread.

Dignity

The main advantage of models with a plastic working part can be called their greater flexibility and lower hardness compared to metal products.This makes it possible to handle significantly more complex and difficult-to-reach surfaces, for example, to remove debris in areas with rugged terrain or sweep it out from under fences, which is difficult to accomplish with a more rigid tool.

The small hardness of the working part allows you to clean areas with fresh crops and seedlings without worrying about their safety - after all, plastic, unlike steel, hardly damages even the most delicate plants.

In the case when a solid obstacle is encountered in the process of work, the plastic teeth bend, and then, due to their high elasticity, restore their original shape, while fan models with a metal wire in such cases require subsequent alignment.

An instrument with a working part made of steel always requires special care. In particular, it must be stored in rooms with low humidity, and after work, it must be thoroughly wiped to remove all wet contamination from the surface. Otherwise, teeth corrosion and subsequent damage can occur.

Of course, a rake with plastic teeth is completely devoid of such a drawback, since it is absolutely resistant to corrosion.

Another important plus of plastic equipment is its noticeably lighter weight and better balancing, since the plastic attachment weighs no more than the handle. Due to this, such a tool is much easier to work with than a metal one, in which the working part has a large mass, noticeably shifting the overall center of gravity of the tool.

Finally, a tool with a plastic working part is often much cheaperthan similar products with steel or aluminum caps.

disadvantages

Low hardness and high flexibility of plastic can be not only a plus, but also a minus.

With a plastic rake, unlike metal rakes, it is almost impossible to carry out work related to soil cultivation... When trying, for example, to loosen relatively hard soil, the teeth will bend at best, and most likely even break. And the overall reliability and resistance to wear and tear of plastic tools is noticeably lower than that of metal ones, which means that their expected service life will be shorter.

In addition to tooth breakages, plastic models are often damaged by the bushing connecting the working part with the handle. Therefore, if possible, it is worth choosing models where this part is reinforced or made of metal.

For a fan rake, see the next video.

The comment was sent successfully.