All about the clay

Clay is one of the oldest construction technologies... In ancient times, when cement technologies were not available or were something primitive like using lime with sand, a clay house was considered the best option.

Peculiarities

Earthenware has certain advantages.

- Minimum cost. Calculations in practice have shown that the cost of sand and firewood, possibly hay, during the construction of walls is, on average, three times less than when using bricks and cement as the main sources of wall strength. The only similarity is that sand is added to the clay to eliminate premature cracking: the fine structure of the clay demonstrates this already in empty areas and a drying country road.

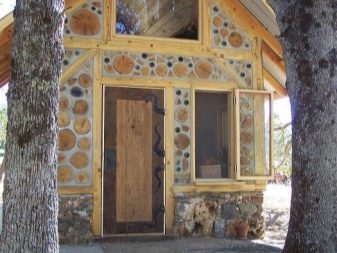

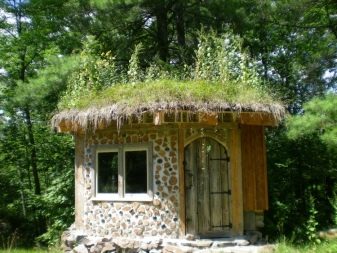

- A house made of clay is no less durable than modern counterparts... The mass and thickness of the walls, the density of wood and fastening materials, superimposed on each other, determine the overall strength and durability of the walls: they are able to hold an attic with a roofing system for decades without any problems.

- Material is available. If there are no hunting or forestry workers nearby, the firewood can be cut by hand or using a cordless circular saw, using a recently felled windbreak as raw material. Cutting whole live trees is prohibited by law.

- With the relentless adherence to SNiP and technological recommendations, the structure will succeed in the literal sense. Exquisitely and tastefully selected finishes, as well as the right marketing techniques that can be learned, sooner or later will find connoisseurs of this skill. Each product has its own verified consumer. Houses made of clay, decorated with sophistication and the best architectural traditions, can be sold for an impressive amount, for example, to groups of people who decide to turn this building into an object for excursions.

- Heat saving at home with insulation, for example, with sawdust, even with a frost of tens of degrees, will prevent the premises from rapidly losing heat from the inside... You can warm the building from the inside with a heater. You can protect the walls from cracking after water ingress from the outside by impregnating them with a waterproof compound.

Clay also has disadvantages.

- If you do not cover the ends of the chocks (firewood) with water-repellent antiseptics, then they can begin to rot from dampness... To prevent water from entering the walls during a rainstorm, it is recommended to make the roof overhangs from 80 cm.

- Wood and clay are susceptible to rodent infestations. Over the course of several years, mice can dig many holes in walls. Strength and heat saving will be lost. First of all, rodents hew and knock down the straw. They gnaw all wood materials and their derivatives, even remotely resembling them. To prevent their intrusion into the house and living in the thickness of the walls all winter, some craftsmen, before plastering the walls, sheathe the house from the outside and from the inside with a metal mesh with a cell of no more than 5 mm. This feature is associated with the fact that the mouse is able to overcome the gap of 6 mm, climbing on the other side of the grid. He will have time to spoil the building materials from which the walls are built, even if he does not later get out.

- The wall covering must be water repellent. Although wood and clay absorb excess moisture and then give it back, it is strongly recommended to paint the chocks and whitewash the clay-sand seams.Artistic painting necessarily involves oil paints and other similar compounds, which are well absorbed into the near-surface micropores of the sand-clay mixture and wood.

Having weighed the advantages and disadvantages and still deciding to build such a house, the owner of the site (master) will begin to translate his project into reality.

What can you build?

The novice master innovator, remembering the forgotten technologies, has the right to start not with the construction of the main house, but with the construction of a makeshift. His focus will be on the following options.

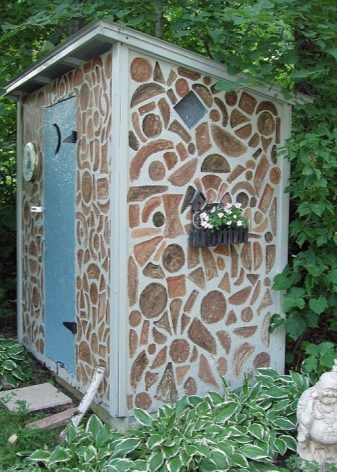

- Barn. This is a farm building that can store firewood for the winter, manual and mechanized garden tools.

- Garage... It doesn't matter what it is built for: for cars, motorcycles or even bicycles, the main thing is to provide protection from rain, snow and hail. To this end, additional measures are being taken: a slope or ramp for the entry of vehicles, raising the finished floor by half a meter and higher above the level of the land plot.

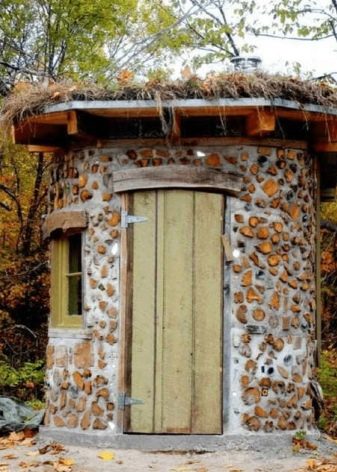

- Bath... Clay is good at keeping warm. And the sauna stove will warm up and dry the structure well. But to protect the main thickness of the walls from excess steam in the steam room and splashing water in the shower, a vapor-permeable finish from the inside is required. Without it, the building will quickly fall apart.

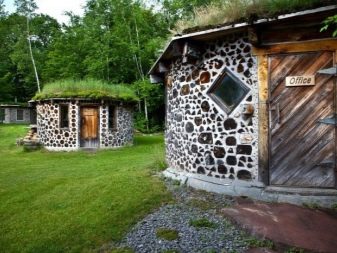

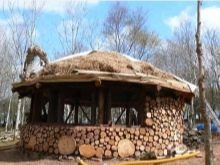

- Gazebo with a canopy... This is not just a lightweight construction that is open to all winds. The construction of walls at least with a significant offset from the corners (at least 1 m) will also be required in this case. The gazebo looks like a structure with four doorways on all sides.

- Chicken coop... No special requirements are needed, only a small window can be installed in it. However, it is necessary to follow the technologies of protection from precipitation.

- Veranda... Created as an extension, but adjacent to the main house. By its construction, it resembles a gazebo, only there is no entrance from each side.

- Toilet... This building, being a summer one, due to the significant (up to 0.8 m) wall thickness will be too costly in terms of the area occupied on the site. The best option is to combine it with a temporary hut, which contains a shower room, washbasin, etc.

Having trained in the construction of secondary premises, if the territory of the site allows, the master proceeds to the construction of a residential building, a bonus to which may be the so-called temporary house - a separate building into which the kitchen can be transferred.

A domed house with a thatched roof is an outdated and questionable solution: the straw is being replaced with a more modern version of the frame, built on the basis of a welded steel "skeleton" of professional pipes, on which the ceiling and roof decking are assembled.

Choice of wood

The harder and denser the type of wood, the stronger (from excess mass) the structure will be. Ideal in terms of strength will be oak or boxwood. If there is no access to such types of wood, then, for example, old poplars, acacia trees: in general, any species growing nearby, up to pine and spruce, will do. Pine wood, by the way, is considered one of the best species of medium hardness. The main criterion is the freshness of the building material. Lumps should be dried in six months in a covered woodpile.

Construction technology

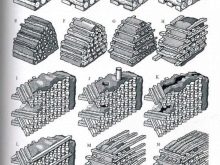

Conservative builders, “grown up” on the modern benefits of civilization, replace clay with ordinary cement-sand mortar of medium hardness. However, it cracks at the first swelling of wood from dampness, as it happens when it gets wet and freezes. Clay with sand, on the other hand, compensates for the swelling of the tree.

The main requirement is to control the verticality of the erected walls with construction level gauges. Do not build by eye, as they did centuries earlier: the structure will succeed with curves, and the beveled square of the rooms will immediately catch your eye even without checking with a tape measure or a laser rangefinder. Subsequently, selling such a house will be unrealistically difficult.

The step-by-step construction instructions are as follows.

- Prepare the foundation. It should be buried 1-2 m.Without a foundation, only carriage-type temporary buildings made of wood, installed on bricks or other ready-made base and transferred to any place on the site, will last for a long time. The fact is that the heaving and movement of the soil can easily displace an unburied base to the side, for example, made from the same trunks of fallen trees, from which all branches and tops have been removed.

- The construction of walls is carried out according to the following scheme... The blocks are laid on layers of clay and sand laid parallel along the contour (installation site) of the walls. In order to insulate future rooms, the internal space is filled with hay, straw, sawdust or modern fillers such as ecowool / mineral wool treated with antiseptics. The length of the chocks is the same, the thickness does not matter. The bark must be removed from them.

- For the organization of window and door openings, lintels are made of timber. It is possible to fold these sections of the walls from chocks, forming round arched transitions at the top, by placing chocks of the same thickness like bricks, forming their even and beautiful arrangement. Pressing on each other with their weight, they do not allow the arched masonry to disperse. If necessary, they are reinforced with strip steel up to several millimeters thick bent along the inner contour of the arch, having drilled both strips and walls of chocks for self-tapping screws.

After finishing laying the walls and arranging the openings, let them dry out of moisture. To prevent the erosion of clay and the collapse of the masonry, the upper parts of the walls are covered with a film or with the help of a tarpaulin or other waterproof materials.

Roofing

Reinforced concrete slabs are unacceptable. Clay is not a technology that uses a major attic-ceiling or interfloor overlap. As in houses made of foam or aerated concrete, it is preferable to use wooden flooring with a base (the floor itself), rafters and lathing made according to the classical technology. For reliable waterproofing of the attic, roofing material is used, and on top you can put both slate or sheet metal profiles, and bituminous tiles.

Facade finishing

Decorating clay with siding or plaster is carried out using the same technologies as refining foam and aerated block walls. The metal thin-walled U-profile, which is most often used in the arrangement of siding, is easily screwed into the chocks using self-tapping screws.

- For this purpose, the wall is marked along the vertical and horizontal arrangement of the corner base., then the chocks are drilled with a 3.2 mm drill at the desired points.

- At the corresponding points, the sections of the corners and profiles themselves are drilled (already with the help of a 4 mm drill). Further, with self-tapping screws with a 4-mm thread diameter, these corners are screwed to the chocks.

- Later, siding is installed according to the classic scheme: the outer edges of the U-profile are drilled, then the siding panels are put on element by element and overlapped into each other.

The advantage of the siding ventilation facade is the perfect drainage of rainwater, protection of the walls from precipitation, even with an oblique rainstorm. Combined with the wide overhang of the roof, your structure will be fully protected from the rain.

If you are not satisfied with the clay siding finish, then waterproof plaster with steel reinforcement using a galvanized cutting mesh is applied for full protection from external influences. The mesh is attached to the chocks with staples using a construction stapler. The surface of the clay wall is slightly moistened. Lime-sand or sand-cement plaster is subsequently applied.

It is more convenient to level the wall along the so-called beacon profile. To do this, it is installed over the mesh.

The evenness of the beacon profile is set using a laser level gauge, using the rule, alabaster or gypsum mixture, cement-sand mortar or other building mixtures are applied.

The comment was sent successfully.