All about plaster

Gypsum is a material that is used in various fields, there are many positive characteristics and advantages that distinguish it favorably from other materials. We would like to draw your attention to a more detailed acquaintance with this product and its varieties. We will also give an overview of manufacturers of building materials.

What is it and what is it made of?

Gypsum is made from gypsum stone. The production is carried out as follows: the stone passes through rotary kilns and is fired, then it is ground to a powdery state. Most often, the material is used in the construction industry for plastering walls. The main advantage of gypsum is its ability to absorb moisture. Products belong to the category of sulfates.

Specifications

Gypsum has a number of technical indicators that you should familiarize yourself with before choosing a material for further work. Gypsum has a fine-grained structure, its bulk density varies from 2.60 to 2.76 g / cm3. If we talk about a loose-filled variety, the indicator reaches 850-1150 kg / m3, in a compacted form, the density is even higher (up to 1455 kg per m3).

It is important to note that the material is manufactured in accordance with GOST, therefore it meets all requirements and standards. One of the advantages of the product is fast hardening and setting, the solution dries easily and sets, hardens in half an hour already four minutes after preparation. This means that the finished material must be used immediately and completely. To slow down this process, specialists mix gypsum with adhesives. The specific gravity is equal to the volume of the material.

Gypsum mortar can be heated, while the properties are preserved. Items made of this material are fire resistant, and even if the temperature exceeds a critical indicator, destruction will occur after 6-8 hours. As for the strength, it should be noted that this indicator under compression is 4-6 MPa, in the high-strength type it reaches 40 MPa, dried samples can be three times stronger. The material does not conduct heat well, it can be easily dissolved in water, but each time it is heated, the solubility decreases.

As you can see, the properties of the building mixture are amazing, which is why it is so often used in different areas.

Types and their application

Gypsum is used in different industries, most of all it is in demand in the construction industry. The material can be used for interior decoration, exterior cladding, acrylic for decorative purposes, fireplaces, ceiling moldings and even stucco elements. During plastering work, specialists cannot do without this solution. Since this is a quick-drying material, it is necessary to work with it quickly, but it all depends on the type of product.

The big advantage is that gypsum products do not crack. Lime mortar gives plasticity to the material, while the need for various aggregates is eliminated. The seizure of the plaster affects the speed of the work performed, so specialists often use retarders to stop this process.

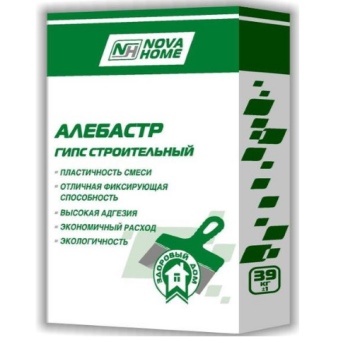

Building

During repair and construction work, one cannot do without such useful material. Gypsum is actively used for grouting, the grout is excellent as plaster and cladding, it can also be used to fasten certain elements.

High strength

The chemical composition of this type of material resembles the previous one, the only difference is lower porosity due to coarse grains. The strength of products made from such gypsum is quite high. Heat treatment is applied during production. Building mixtures are made from it, partitions are erected that cannot burn out. For the release of sanitary ware from porcelain and earthenware, such a solution is also required. It is impossible not to note the field of medicine, which does not do without gypsum, it is actively used in its various directions.

Cellacast

From such plaster, bandages are created, the structure of which is quite plastic, so it is easy and simple to make bandages from them.

It is safe to say that cellacast with its technical characteristics resembles a polymer bandage.

Polymeric

Orthopedic traumatologists work with this material during bandaging. The main advantages of the material include easy operation, breathability, moisture resistance, light weight and the ability to control the state of bones using X-rays.

Sculptural

Such gypsum is considered the most highly durable; various sculptures and arches are created from it.... There are no other mixtures in the composition, so the natural whiteness is preserved. The material is excellent for sculpting souvenirs, while it is used in the automotive, porcelain and faience and aviation industries. Sculptural gypsum acts as the main component in dry mixes for puttying. The foundry mortar is obtained from the mortar by sieving and grinding. It should be noted that plaster molding has been in demand for many centuries; original decor can be created from the material, which remains relevant to this day.

White

Such gypsum is suitable for sealing seams and cracks, stucco molding is also made from it, with its help a number of other construction and repair work is carried out. This material has excellent compatibility with other building mixtures. It is important to take into account that it hardens in 10 minutes, so it is better to cook it in small quantities and use it right away.

Acrylic

For production, resin is used, after hardening it is ordinary gypsum, which has the only difference - light weight. Thanks to these characteristics, the material is suitable for creating decorative elements and stucco moldings. The main properties include frost resistance, low moisture absorption, so it is used for facing facades. It is pleasant to work with the material, sometimes crumbs or special aluminum powder is added to it, due to which an original effect is achieved.

Polyurethane

Polystyrene material is offered at a lower price than conventional material, while its characteristics are practically the same.

Other

Translucent plaster is fine-grained, so this option is excellent for filling joints and joining slabs. The material in liquid form is prepared from powder and water, so the density can be selected independently, based on the scope of application. Moisture resistant gypsum is obtained as a result of processing raw materials using a special technology, to improve the properties of the product, vinasse is added.

Gypsum is a non-combustible material, but when it comes to sheets, this characteristic does not apply. To impart fire resistance, it is better to use a tongue-and-groove mixture. Has a high level of plasticity architectural kind, there are no toxic constituents in it.

Many designers choose this material because it is convenient and easy to work with.

Marking

Different brands of gypsum are offered on the market, this indicator is always indicated on packs in the form of letters A, B, C. You need to understand this in order to choose the material most suitable for work, taking into account all the properties and characteristics, because the composition can be fast, normal and slow hardening. It should be noted that manufacturers divide products according to the degree of powder grinding - coarse, medium and fine. The first option is denoted by the Roman numeral l, respectively, the second - ll, and the third - lll.

Parts made of fine powder will have a better surface. The classification is based on strength, so about 12 varieties can be found on the market, they may look like this - G-13, G-5, G-6, etc. The number denotes compressive strength, measured in megapascals. The bags are marked with markings that you can decipher yourself to determine the degree of strength, hardening time and type of grinding.

Manufacturers overview

To find quality material for work, it is necessary not only to determine the type of product, but also to learn about the leading manufacturers who guarantee quality... The domestic market has a wide selection of brands that have earned the attention of consumers. For example, a company Samaragips offers "Smart Plaster" for the creation of figures and architectural products. The assortment has several varieties of this material for certain works.

Samara Gypsum Plant has been providing its services for many years. The products are highly durable, reliable and are supplied in a wide variety to any region.

"Angarsk gypsum plant" has existed for 60 years and specializes in the manufacture of building materials, among which there is a wide selection of dry mixes. The company produces about 6 thousand tons per month, which cannot but surprise. Company "CherkesskStroyProduct" is one of the leading manufacturers in the domestic market, it supplies high-strength gypsum of such brands as GVVS-16, GVVS-19 sculptural, GVVS-25, G-5, etc.

These products are actively used in construction.

Additional materials

The composition of gypsum includes such a fragile component as calcium, so it will not be possible to do without impurities and additives. In factories, impregnations are used to fill the pores of the surface of products, only after that paint can be applied. Natural drying oil acts as an impregnating material, but it can be easily replaced by liquid glass or ordinary PVA glue. It is extremely important to wait until it dries and only then cover the material with a dye or varnish. Another additive is a plasticizer, thanks to which it is possible to change the setting time of the mortar and even control the fluidity.

To reduce water absorption, a water repellent should be used, while it retains vapor permeability, which is important. Condensation will not appear on the surface of the gypsum product when the temperature changes. Varnishes are a facing material for the treatment of gypsum products, they close the pores to reduce the absorbency of the gypsum. The composition penetrates deeply into all cracks, resulting in the formation of a strong thin film with good adhesion.

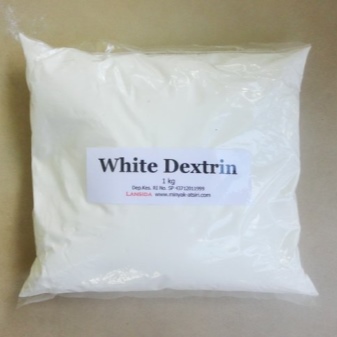

Since gypsum hardens quickly, sometimes you have to resort to additives that would slow down this process, especially when it comes to large-scale work. Sodium tartrate or sodium citrate is used as this substance. Sometimes experts add citric acid or Dextrin to the solution.

How to do it at home?

Loose material is actively used not only at large construction sites and factories, but also in everyday life, because it can be used to make various products, decorative elements, etc. Therefore, if you want to do it yourself, you only need a few ingredients and a mixing container for cooking. Water is poured into the vessel, then the dry mixture is slowly poured, while stirring everything thoroughly.It is important to observe the speed here so that the solution does not become solid before you use it, it should be made in 2 minutes, using only cold water. The consistency should resemble liquid sour cream, if there is too much water, it is enough to add the mixture.

As soon as everything is ready, it is necessary to start using the gypsum, it is recommended to dilute the mixture in small portions, especially if this is the first experience with dry compositions.

How to work with plaster?

Before you start mixing gypsum powder, you need to calculate the proportions, taking into account the amount of material that was required.... During hardening, the amount of solution will increase slightly, heat will begin to be released, due to this, during repair and construction work, the material will fill all the grooves and cracks, at the same time it will repeat the internal volume of the mold if you pour it into special containers for making jewelry and details.

To mix the dry mixture evenly, you can use a stainless steel or wood tool. If we are talking about a large volume, an electric drill with a special attachment will help. The strength can be increased by various additives mentioned above. After the gypsum product is completely ready, it is recommended to impregnate it with varnish to eliminate porosity.

If you need to make a mold for wax, bronze or plexiglass, there is no better option than plaster. You can mold the mold yourself, it is a quick and easy process... To do this, you need a prepared box or container into which you need to pour the solution so that it covers the entire inner part with a thin layer. After hardening, the surface is treated with a lubricant, filled with a solution up to half and left to harden. In this way, the lower part is created, after which you can tackle the upper part. Various components can be added to gypsum to improve its properties, which is one of the reasons for such widespread use.

The comment was sent successfully.