All about hydraulic presses

Hydraulics can do much more than mechanics: higher recoil, reaching up to 90% and slightly higher, subtle modulation of movements, the ability of craftsmen to "feel" the units that have replaced "clean" mechanics, which works exclusively on teeth and bearings.

What it is?

Known as a separate device since 1795, the hydraulic press is based on the possibility of creating a significant compressive effect through the use of a liquid column as a transfer substance. In terms of strength (kilograms of effort per square centimeter of workpiece), a purely mechanical press is noticeably inferior to a hydromechanical press: the efficiency of mechanics is within 60-80%. The device and the principle of operation of the unit are as follows.

- To measure the pressure, the reservoir of the hydraulic press is connected to a manometer, which displays the value of the real pressure of the liquid. Basically, industrial or transmission oil is used as such a fluid - analogs of brake fluid, such as those used, for example, in brake pads.

- In horizontal section, a simple press includes two communicating cylindrical vessels. The diameters of the pistons in these vessels vary. In the simplest case, the cylinders are filled with water, but in order to increase their durability (rusting steel is used as the main material), oil is usually used (brake, transmission, industrial or transformer oil).

- Based on the pattern identified by Pascal, they are guided by the following fact: the pressure at any point in space filled with a stationary fluid does not differ, and the forces acting on the pistons are proportional to the areas of the latter. The hydraulic press without disadvantages has an additional force equal to the ratio of the areas of the pistons. When acting on a small of the pistons, the force transmitted by the oil will appear under both pistons.

The purpose of any press is to compress the parts being formed.

In the simplest case, a hydraulic press is used to make blanks from pressed materials. For example, the use of a hydraulic press in the food industry involves pressing whole sunflower seeds mixed with sugar molasses into separate blocks - kozinaki. The oil press is also used to squeeze oil from the seeds of the same sunflower. In metalworking, this is, for example, the pressing of steel powder sintered at a high temperature (for example, the smallest waste after drilling, sawing, corrugation of steel parts is combined into a block).

Views

The vulcanizing press works as follows. Pressing molds are placed on the working platforms of the device, in which the raw rubber is placed. The platforms squeeze the material, which is why the forms take on a closed position. Compared to vulcanized rubber, raw rubber is distributed in the spaces of the mold due to its greater fluidity. Then the molds are heated, and the rubber heats up with them - hardening, it takes on its now unchanged shape. At the end of the production interval, during which the rubber products are being prepared, the molds release the “sintered” contents. The operation of the pressing plants is controlled using computer technology.It is necessary to lay in the raw rubber and remove the finished one by hand.

An industrial press, for example, for pressing oil from sunflower seeds, has a screw drive. Here, the main operating mechanism, in addition to square, round or rectangular plates, is also considered to be the guides along which the movable platform is lowered to the stationary one and rises back, as well as one or several powerful screws, to which sliding bushings are attached. The latter can be implemented on the same powerful bearings to ensure smooth rotation of the screw, preventing it from being screwed into the plate itself. But the press can also be made on the basis of a jack, the main rule is that the squeezing device for obtaining liquid products of production should be located so that the movable and stationary plates are parallel to the earth's horizon, and the squeezing chamber has an outlet pipe, of which the outlet (outlet) channel consists.

Floor press - usually a non-mobile device, for the transportation of which (repair of the device, relocation of production, or other) you will need a car.

Placed on the floor or on a powerful workbench - in general, on a previously prepared base, which must be reinforced.

Baler - a device designed for packaging, for example, waste. It is made on the basis of a jack or a vice in a garage environment. It is used for the disposal of plastic bottles (PET containers). The baling press can easily compress and pack waste paper, wrappers and bags, old plastic and rubber toys, worn tires and chambers punctured in many places.

The valve press can be equipped with a valve motor, which makes it quick to use. The valve motor is taken the most powerful - from tens of kilowatts, and is mainly used on the production conveyor, where the volume of products is the highest. A quarter of a revolution of the engine is enough to push one of the pistons with the right force, and the desired effect is immediately achieved.

The punching (cut-out, stamping) unit is used in the production of parts from metals and alloys by hot and cold stamping. It is structured as follows: the movable (and fixed) plates are equipped with recesses and protrusions that form metal sheets in the form of an open (open in cross-section) profile, all kinds of components that do not have a large length. With the help of a punching press, a bent U-shaped profile, staples, ties, steel gaskets with technological gaps of an arbitrary (specified) shape are made.

By arrangement of cylinders

The vertical arrangement of the cylinders (containers with oil), in which the pistons reciprocate, depending on the force applied from the outside, is a classic version. The vertical cylinder is installed in devices such as top or bottom.

The horizontal arrangement of the pistons is used, for example, in rooms with low ceilings, in conditions of limited space at the top, necessary for the normal operation of the pressing machine. The advantage of horizontal presses is vibration damping, better maneuverability during compression. The angular arrangement of the cylinders provides for vertical and horizontal cylinders.

By the number of cylinders

A hydraulic press has no more than a few cylinders. However, in practice, "home-made" people mainly use one- and two-cylinder units.

Production units have more advanced features, for example, the presence of three or four cylinders.

By design

The frame structure is a closed type of press, suitable for crimping parts of a small section (width and height). The open frame is suitable for large parts - for example, for pressing steel sheets from 1 m wide into a complex profile (stamping).

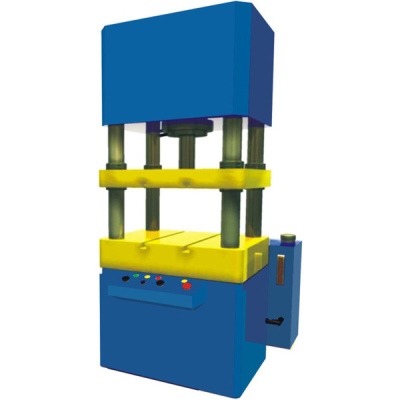

The column press resembles a movable structure moving on four guides of a circular cross-section. There can be one or two groups of columns - to some extent it resembles a telescopic structure. Two sets of columns (4 each) may require two movable platforms to press tall workpieces. You can stop the moving mechanism at any time - at some stages, technological pauses are required.

The jaw structure is like a crimping tool, enlarged tens and hundreds of times, in which the upper part - or both parts - is movable. The jaw press is somewhat similar to giant pliers, but with smooth pressure edges. However, stamping presses have ribbed edges, depending on the types and varieties of stamping products.

By drive type

The manual drive is driven by a conventional screw with a knob, or by means of levers. Electromechanics, on the other hand, transmits power to the hydraulics using a motor. For example, a stepper or a valve motor is used as a drive, operating from a pulsed-constant voltage supplied by the electronic board of the commutator driver to certain windings. Those, in turn, generating a magnetic field at certain times, interact with their own field from the magnets on the rotor. As a result, the rotor turns to the desired angle, or makes a certain number of revolutions, the energy of which is used to move the pistons to a certain height.

The electric motor can be replaced with a liquid fuel engine.

The advantage of motor drives and diesel installations is high power - from tens of kilowatts - with relatively low fuel costs.

Spare parts and components

For maintenance (and repair) of the press machine, the following spare parts and parts are used, which are replaced if any component breaks down. RThe repair is carried out by replacing spare parts with the same ones with similar outlines, clearances, dimensions.

The simplest components for the press include pistons with gaskets, springs, bolts, nuts, pressing and grooving washers, levers, an electric motor, gear parts (used in combined presses). Since the universal press is collapsible - it can be easily assembled, as well as disassembled and transferred to another place - the squeezing plates and guides are made in the form of detachable parts. Only the frame is made whole (welded), the rest of the joints and fasteners can be made using bolted connections from M-14 to M-20. It is not recommended to use smaller sizes (diameters of the working part) of the bolts, since for a force weighing up to 30 tons, M10 and M12 bolts will obviously not be enough, and the device will regularly fail at the most "loaded" critical moments.

For maintenance and repair (replacement of components) of self-made presses, a jack can be used - entirely when the press is built on its basis - and the previous jack failed, for example, a cylinder burst or a rod broke. Partial repair of the jack is also possible, for example, changing the oil, changing the gaskets of the piston that relieves the pressure of the valve.

Industrial presses require highly specialized parts: mandrels, matrix, valves, cylinder tips, oil seals of different diameters, handles for levers, frame jumpers, pump-to-handle connectors, as well as ready-made (simplest) repair kits. In the last 20 years, unification and standardization of most presses has been observed, their repair compatibility is ensured - for example, glands and connectors can be suitable for model lines from several manufacturers.

Selection Tips

The press is a super-heavy tool both in terms of weight and pressure. The prototype of the press is a vice and a clamp, but, as a rule, in practice, they do not provide a force of more than a couple of tons. For a start, a press for an effort of 10, 12, 20 tons is suitable. In the course of further mastering of production operations, increasing the throughput of your production point, it makes sense to sell this press - and purchase an installation for 30, 40, 50 or 100 tons.

Some craftsmen use an open frame press - for the manufacture of pivots, extrusion of bearing elements.

The size of the equipment is determined by the size of the production site.

For example, for a garage of 36 m2 (the space is single and is a workshop), you can purchase or assemble a press for a 30-ton force, which will require several square meters of space to work on (the installation itself takes, for example, 2 m2 - 1x2 m) ...

Applications

The hydraulic press is used for the following types, types and varieties of work:

- pressing of bearings;

- briquetting of waste - sawdust, synthetic waste, waste paper, wood (plant) waste;

- pressing of edible oils, juices;

- for punching holes - for example, it is necessary to press (push) the holes in a strict sequence on an aluminum or plastic blank, which makes it easier to copy uniform, similar parts;

- crimping, molding of profiles, staples by hot and cold methods.

There are dozens of types of work where it is not just difficult to do without a press, but absolutely impossible. Each of these varieties has its own specifics. For example, squeezing vegetable oil takes an average of 12 minutes per session, and on most home-made installations during this time, a batch of 7 kg of unpeeled (unhulled) raw seeds is squeezed out.

How to use it correctly?

Before using the press, check the presence and level of oil. Air bubbles trapped in the unit must be vented - the oil must not contain them. If they are left, the pressure exerted will be far from the calculated one - especially in installations where the immersion depth of the pistons is not regulated by the machine operator, but is rigidly set by a motor drive with CNC (or without computer control). If you do not bleed air, do not add oil, then the downforce will be insufficient, despite the fact that the pressure gauge on the press shows a significantly lower pressure.

Before turning on and testing the press, an external inspection by the machine operator reveals conspicuous damage. For example, you cannot work on a press, on which a crack suddenly appears on the frame (not thoroughly welded joint). With the development of force, it can burst, and the operator working manually on a lever-type (manual) press is more likely to be injured due to a sudden loss of control.

For greater safety of use, fastening connections are tightened with loose fasteners. The parts, on which the working pressure is produced, as well as the moving elements of the machine, are covered with lithol or grease. The seals of sliders and valves are checked for breaks and cracks, if necessary, they are replaced with new ones. This makes it possible to avoid oil leakage. The oil itself is changed once a year.

Pipe channels, for example, the communication of oil-cylinder tanks, are designed for an operating pressure of about 400 atmospheres: they serve for a year and a half, then, due to steel fatigue, they must be replaced.

To save money on changing the oil, clean it from deposits: the missing volume can simply be topped up - according to the situation. It is not recommended to fill in the entire volume of oil: every liter counts, and new engine oil is not cheap. The oil is filtered regularly - at least once a year. Steel particles are cleaned using a tube with magnets: after a while, these particles stick to it.

Do not start work on the press if not all the workpieces to be processed are present. Batch processing of batches of parts speeds up the production process, gives a great return. Do not press the next batch of parts without removing all the previous ones: re-stamping may reject some of them. In general, for any peculiarities of the upcoming work, be guided by the description of the press. For example, a press for squeezing is not suitable for stamping parts: for this, smooth removable plates are replaced with profiled ones.

The comment was sent successfully.