Characteristics of Soudal sealants

When starting repairs in the house, it is necessary to remember both the basic and additional materials, which you cannot do without. Sealants are important components of the workflow. Their main task is to seal cracks and cracks. Sealants help protect the material from temperature extremes and excessive humidity, as well as from adverse external influences. When choosing such products, you need to focus on the type of work in which the funds will be used.

Soudal is considered the largest manufacturer of such materials. For half a century of its work, it has received well-deserved recognition in the world market. Its products are used by both self-repairing people and professional builders.

Peculiarities

Soudal sealants have a number of valuable characteristics that underline their high quality and reliability. These are resistance to ultraviolet rays, good tolerance to moisture and other external influences, ease of use and long service life.

Any sealant contains polymers. Depending on their type, the characteristics of the product itself are determined. One of the best known is the Soudaflex sealant. It is based on polyurethane, is characterized by good adhesion to other materials and elasticity after application. Its application does not cause problems and does not require special skills.

Types and technical characteristics

There is a wide variety of sealants on the market that are suitable for a variety of applications. They are packaged in tubes of various sizes and shapes. There are universal, fire-resistant, silicone, sanitary, aquarium products. The most commonly used types are acrylic, silicone and polyurethane.

Silicone sealants have gained the widest popularity. As the name implies, the basis of the product is silicone. The product is presented on the market in a wide variety of colors - transparent, white, black, beige and bronze. It is the color of the material that affects its basic properties. The product is used for external and internal work.

Silicone sealants are divided into neutral and acidic. They can be used for work carried out in high humidity. They stretch up to 250 percent, do not lose their properties when the temperature fluctuates from -40 to +100 degrees, when exposed to pressure and other atmospheric phenomena. Also, such funds perfectly tolerate mechanical stress. Sealants of this group are in good contact with a large number of surfaces. They can be used when working with concrete, brick, glass and other substrates.

The next type is acrylic sealants. They have a lot in common with silicone, but they also have distinctive features. The products are available in different colors, and are more often used for indoor work. These materials can be used in rooms with high humidity, they do not change their color under the influence of moisture. They are also resistant to mold and mildew.

Non-moisture resistant sealants of this group have excellent aesthetic properties and are often used in furniture assembly. They are ideal for working with wood products (door and window frames, flooring, etc.). The products dry out in a short period of time. For example, a fast drying acrylic sealant "Soudal Acrylic Express" can be processed and coated with paints and varnishes 10-15 minutes after application.

The main disadvantage of acrylic sealants is their inelasticity.Therefore, in case of a possible change in the size of cracks during operation, the use of such products should be abandoned. Although they are quite resistant to temperature extremes, they tolerate fluctuations in the range from -30 to +75 degrees.

The most resistant, reliable and durable polyurethane sealants are recognized. They are used mainly for external work, they are suitable for sealing the seams of building objects. Like silicone, these products can stretch up to 250 percent. They are resistant to temperature fluctuations from -40 to +80 degrees, they tolerate most natural phenomena, high humidity and ultraviolet radiation well.

This type of sealant is recommended for use with brick, wood and stone. After coating with varnishes and paint, they do not lose their properties. However, the chemical composition of such products is quite aggressive, therefore, during work, care should be taken to avoid allergic reactions.

One example of a commonly used sealant from this manufacturer is Soudaflex 14 LM. It is available in 310 and 600 ml volumes. The product is produced in white, gray, light and dark brown, dark beige colors. It interacts well with most materials, it is used to seal vertical joints, because due to its consistency, it does not flow out of them. The product does not lose its properties when coated with paints and varnishes, it can withstand loads well.

Another popular brand is Soudaflex 40 FC... This sealant is available in the same quantities as the previous one, and can be black, white and gray. Its elasticity allows it to seal vibration-resistant seams, as well as to perform many other tasks during construction work. The product interacts well with a large number of materials, it is often used when working with concrete. It perfectly tolerates even serious loads, it is easy to paint.

Sealant Fix All Classic can be used for both outdoor and indoor work. Its distinctive feature is the ability to interact even with wet materials. The product is chemically neutral, interacts well with most surfaces (from plastics to metals). The product is resistant to weak alkalis and solvents.

Instructions for use

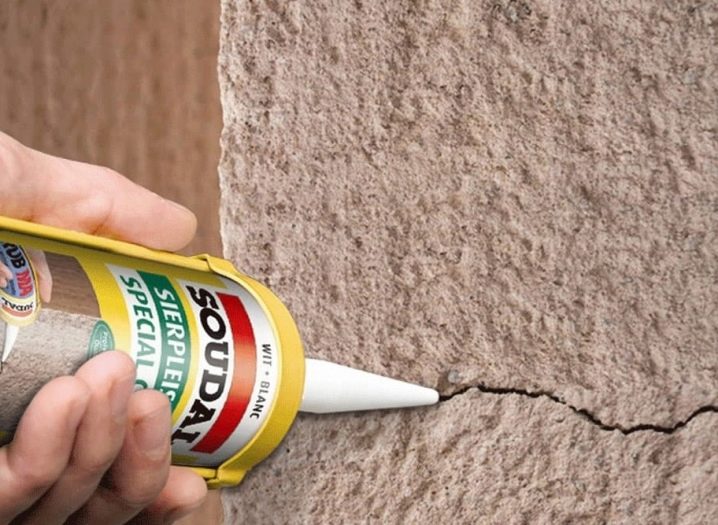

- First of all, the surface is prepared. It must be cleaned, degreased and dried. To prevent the sealant from getting on the outer part of the coating, it must be sealed with masking tape.

- It is recommended to use protective clothing and gloves when working with sealants.

- It is more convenient to apply the composition using an assembly gun. How to use it is usually indicated on the label. The composition must be applied at an angle of 45 degrees. For faster drying, it is recommended to avoid the formation of a thick layer. Excess sealant is removed with a spatula.

- Drying time depends on both the type of sealant used and the thickness of the applied strip. Usually this process takes about a day, but the material begins to harden after half an hour.

To avoid application problems, it is recommended to examine the label before use. It indicates the properties and scope of the composition, instructions for its application, the time it takes to dry, as well as the expiration date.

Where is it used?

Soudal's sealants are used in a variety of construction and renovation applications. Their use depends on the type of composition and its properties. For example, sanitary sealants are ideal for bathrooms and kitchens. They are highly resistant to moisture, antibacterial and antifungal properties.

When renovating indoors, preference is given to acrylic compounds. For example, acrylic parquet sealant is designed to work with parquet and laminate flooring. It does an excellent job of pinning a profile and a lot of other tasks. Bituminous sealant is used for foundation and roof repair.It withstands moisture and temperature extremes well.

Universal compounds are excellent for working with wood, used to seal cracks on window and door frames. Neutral silicone sealant (eg Silirub 2) can be used for alkaline substrates and metal applications. It is characterized by resistance to all weather conditions and is used for both external and internal work.

The aquarium silicone sealant is completely non-toxic. It tolerates water well, is elastic and dries quickly. This type of material is used in bathrooms and showers, ideal for aquariums.

Heat-resistant high-temperature sealants withstand temperatures up to +300 degrees, therefore they are suitable for stoves, chimneys, heating pipes, as well as industrial and electrical work.

In various fields, adhesive sealant is actively used. Such materials are widely used in the shipbuilding and automotive industries when working with wood, brick, concrete, stone and other materials.

The following video shows how Soudaflex 40 FC is tested.

The comment was sent successfully.