Features of thread sealant

The thread sealant is designed to make the joints of gas, heating or plumbing pipes as tight as possible. When choosing a suitable option, it is worth considering all the features of thread sealants, navigating among the whole variety of types, keeping in mind both the old-fashioned methods of sealing and the use of modern anaerobic gels.

Peculiarities

When starting a major overhaul, many think about the tightness of pipes in the last place, but in vain. After all, it depends on how high the likelihood is that everything can be ruined by an unexpected leak. This is especially true when the pipes run near expensive equipment: this way the damage to the family budget will be more than tangible. However, many find the simplest solutions, using improvised means to seal the thread: tow, threads, plasticine. All this does not provide the required isolation. And this is where the time comes to pay special attention to professional thread sealants.

Professional materials include fum tapes, teflon threads and anaerobic gels. It is worth dwelling on the latter in more detail. Recently, they have been used more often than others, since they provide an optimal level of pipe adhesion, completely sealing the thread. A properly applied anaerobic sealant can withstand 50 atmospheres of pressure, not to mention vibration loads. In general, such a sealant is the best choice for domestic use, and in professional facilities, it will work just as well.

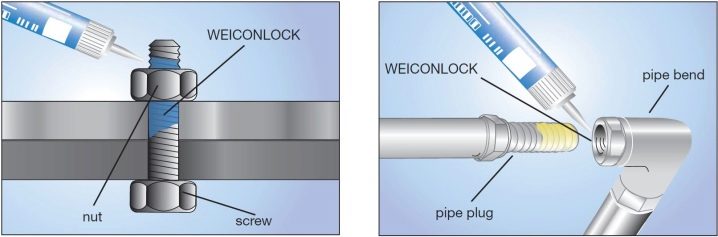

The main feature of anaerobic gel is that it begins to solidify only when the nut or joint is tightened and air access to the sealant is blocked. As a result, the connection is obtained, one might say, monolithic, and practically no mechanical efforts can break it. Only ultra-high temperatures help, which can only be obtained using special tools (for example, a construction hair dryer). It is safe to say that heating pipes can also be sealed with a gel, and the durability of the joints will be at a height despite the temperature drops.

If you apply the anaerobic gel according to all the rules, then it will last from 5 years or longer. If the technology has not been properly followed, then the guaranteed service life will be only a year. However, even a one-year warranty is more than can be expected using non-professional tools and materials. Many people complain that anaerobic binders are too expensive (the average price varies from 1,500 to 2,000 rubles for a 50 ml tube), but practice shows that such sealants are worth their money, because repairs in which case will cost much more. In addition, the gel is economical, and it is quite possible that such a tube will be enough to seal all the plumbing and communication pipes in the apartment.

Thus, it is safe to say that the popularity of anaerobic sealants is due precisely to their characteristics.

Views

On the basis of anaerobic sealants are divided into those based on the composition of the oligomer, and based on polymers of the acrylic group. Both those and others have similar qualities: they withstand high pressure, are not subject to the negative influence of mechanical stress, and so on. The difference is important only for professional chemists, construction specialists do not pay attention to this parameter when choosing.

It is much more important to separate the sealants according to the degree of fixation. There are options for strong hold, medium (universal) and low.

Low retention agents are used when a small diameter pipe connection is to be sealed. The clamp does not tolerate vibrations and vibrations well, and the pipe itself can be easily untwisted with the help of improvised tools. This makes the use of a low hold sealant an excellent choice when you only need to connect the pipes temporarily and are planning to dismantle them soon. You can use this type for long-term use, but on condition that during operation, the threaded connection will not be subjected to significant loads.

Medium fixation pastes and gels are most often used in everyday life. They are suitable for sealing heating systems, gas pipelines, water supply systems, and their use is absolutely harmless and does not change the quality of drinking water. That is why sealants of this type are called universal. They firmly fix the thread, but it is possible to dismantle the joint in the future, only for this it will be necessary to use specialized equipment. The latch withstands the loads that are produced by batteries, water pipes and plumbing.

Strong fixation in a domestic environment is not needed. Such sealants hold the pipes together forever and further dismantling is impossible. They are, as a rule, used in industrial production: factories, factories, in the arrangement of the city sewer network. These clamps are much more expensive than household clamps and require special knowledge and skills when working with them, because you will have to act quickly and accurately. The connection turns out to be inseparable and in the future, if necessary, the joint will have to be sawed.

Commonly used medium hold sealants are also classified. In this case, the classification category is the degree of viscosity of the drug. The finer and more frequent the thread, the thinner the sealant must be so that it can optimally fill the entire airspace of the joint. The maximum pipe diameter for which anaerobic gels and pastes are produced is 4 cm. Large pipes are sealed in other ways.

Colors

The most important criterion by which one can immediately draw a conclusion about what the sealant is used for and what properties it has is color. Anaerobic thread sealants are available in several colors.

Blue

Typically, blue anaerobic sealants are only suitable for metal pipes and fittings. The joint turns out to be resistant to all kinds of influences, be it water, gas, antifreeze, gasoline, and the like. The blue retainer is a high quality seal that has only recently been used in the home. Previously, it was only available in industrial production, for example, in the construction of defense structures, missiles, spaceships. The application is limited only by the diameter of the pipes: it should not exceed two centimeters. Dismantling can be done without special equipment by applying medium mechanical forces.

Red

Red sealants are needed to seal worn, worn threads. Also, red sealants are used for sealing ferrous metal pipe joints. Red clips set faster than others, but this does not affect their strength properties in any way. They are resistant to high pressure and temperature extremes. The diameter of the pipes that can be sealed with this anaerobic gel is no more than 3 cm. Dismantling will definitely require heating the junction. When repairing, it is not necessary to remove excess thread sealant, you can apply a new coat directly on top of them.

Green

The green sealant belongs to the low-strength varieties. It is suitable for the temporary connection of both plastic and metal pipes.When dismantling it, no effort is required: it will be enough to untwist the connection, as usual. Manufacturers say there is little difference between blue and green, but this is not the case. Blue is resistant to all kinds of influences, vibrations, which cannot be said about green. The green retainer can be used to seal pipes up to 3.81 cm (1.5 in.) In diameter. The important point is that the threads must not be damaged.

Scope of application

Anaerobic sealants were invented in the 1950s in the United States and were initially used only in industrial areas. Later they came to the USSR, and with the decline of the industrial complex, the manufacturers of sealants tried to popularize their products and find new applications for them. So anaerobic gels and pastes migrated to construction.

It was originally forbidden to use them when sealing water pipes., since it was believed that their contact with water poisons it, and the water cannot be drunk in the future. However, further studies have shown that the compounds used in anaerobic fixatives are completely safe.

Currently, thread sealants are used in several areas.

- Water supply. Water pipes in apartments and houses are sealed with an anaerobic gel. They are not suitable for insulation of pipes located on the street due to the impossibility of sealing large diameters. The clamps are also suitable for insulating sewer pipe joints, since they are able to withstand high water pressure. Better to use blue sealants.

- Plumbing. Water is supplied to the plumbing using pipes, the connection of which must also be made airtight. For this, a sealant is again used that is resistant to high temperature fluctuations. This is especially important, for example, when connecting a washing machine. Care must be taken to ensure that the clamp is suitable for sealing plastic pipes.

- Heating. As in the previous case, the sealant must withstand temperature fluctuations, as well as be resistant to heating antifreezes and other chemical compounds. If Soviet cast-iron radiators are insulated, then it is necessary to use only red varieties of anaerobic gels, since others are not designed to work with ferrous metals.

- Gas pipeline. Here, the tightness of the pipes is especially important, since a gas leak will lead to damage to property through an explosion. You can also lose your life. You cannot use green sealant, only blue. It is also not advisable to use red, since it will be impossible to dismantle it if necessary. It is best to entrust the sealing of gas pipelines to professionals in order to avoid possible mistakes.

Advantages and disadvantages

After reviewing the theoretical information regarding anaerobic thread sealants, you can compile a list of their positive and negative features. Since there are many times more advantages than disadvantages, you should start with the first ones.

The advantages are several.

- High heat capacity of joints. The sealant will not degrade even when exposed to strong temperature fluctuations. Typically, the allowable level varies between -200 degrees and +300 degrees. All this allows the use of liquid anaerobic gels when connecting heating radiators or water pipes with hot water.

- Durability and strength. The joint will not disintegrate, will not crack under the influence of mechanical loads or vibrations, so you can be calm about the fact that the pipe may leak due to the fact that the water was let through the pipes a little more intensively.

- Saving. In the long term, it turns out to save on repair and renewal of the sealant on the pipe joints. In addition, the composition itself is also economical during operation. It will literally need a drop to process a whole thread.

- Chemical resistance.This feature is one of those that influenced the popularization of anaerobic sealants. Unlike improvised materials and some professional ones, gels and pastes with anaerobic properties easily tolerate the effects of chemical compounds and substances such as gasoline, antifreeze and the like.

- Lack of water solubility. After passing the polymerization process, the sealant does not dissolve with water, does not dissolve in it, so it can be safely used when sealing water pipes, without fear that over time the sealant will completely dissolve and the pipe will leak.

- Versatility. This means that the fixture can be used when working with various materials, including in cases where one part is made of one material, and the other is made of another. So, the most common example is the connection of a plastic pipe with a metal one.

- Ability to withstand high pressure. Resistance to resist pressure should be taken out as a separate feature, since it is most often of interest to buyers. Joints treated with an anaerobic sealant are able to withstand a pressure of 40-50 atmospheres.

In addition to the listed advantages, the tool also has a number of disadvantages.

- Correlation with temperatures. The pour point should be between 15 and 25 degrees. In a room that is too cold, the polymerization time of the sealant will greatly increase and its properties may change.

- Diameter limitation. It is impossible to find an anaerobic gel that can be applied to pipes with a diameter of more than 4 cm without losing the lion's share of its technical characteristics.

- Dependence on surface cleanliness. Before applying the fixative, the surface must be properly prepared: clean, degrease and dry. Otherwise, it will not be possible to completely seal the joint.

- Difficulty in dismantling. Only temporary green sealants can be removed manually. Blues will need special equipment such as a hair dryer. It is generally impossible to dismantle the red ones: the pipe will have to be sawed.

How to use?

It is worth mentioning in advance that anaerobic gels and pastes are available ready for use. It is not necessary to additionally prepare solutions and compositions. The container in which they are sold is designed for the drug to be applied directly from it, although you can use all kinds of brushes if it is more convenient.

The order of work.

- The surface is thoroughly cleaned. Any traces of rust, corrosion are removed. If there are traces of old sealant at the place of application, then it is not necessary to completely remove it: small particles will not affect the quality of the seal in any way. If the pipe is new, it is enough to walk along the thread with a wire brush to improve the adhesive properties.

- The cleaned surface is degreased. For this, all kinds of compositions are suitable, for example, white spirit. Degreasing must be done thoroughly, without missing a single gap. It is important that the anaerobic gel adheres well. A special activator must be applied to the plastic thread.

- Next, the composition itself is prepared. The tube shakes well. Only then can the package be opened.

- The sealant is applied to the joint with a thick layer along the entire thread. Some masters advise to apply the composition only on a few turns, since this does not greatly affect the tightness of the joint, however, if you are processing a pipe that will be under high pressure in the future, it is better not to risk it. For optimal sealing, the sealant is applied not only from the outside of the joint, but also from the inside: this way an optimal effect can be achieved.

- Tighten the connection after applying the gel. To do this, you do not need to exert excessive force, just tighten by hand. If the sealant has come out, it is collected with a napkin.The composition does not freeze in air, so the sealant can be reused by applying to another compound.

- Next, the joint is checked for tightness. To do this, after 15-25 minutes, you need to create a small pressure of 10-15 atmospheres, letting in water or gas. If everything is in order, then you must wait until it hardens completely.

- Full polymerization takes place in a day. After this time, a second test is performed, but the pressure should already be 40 atmospheres. If everything is working properly, then pipes can be used. If not, then dismantle and reseal.

- If it is necessary to dismantle the joint, then the order of work will be as follows:

- the flow of hot air from the construction hair dryer is directed to the junction;

- the moment is awaited when the retainer turns into crumb;

- the connection is disassembled with a key;

- the remains of anaerobic gel or paste are removed with a cloth.

Having done all the work correctly, you can not worry about the durability of the joint service.

Manufacturers

You can argue for a long time about which manufacturer is better, so the simplest thing is to refer to reviews. Several brands receive the most positive ratings.

- Loctite. A universal adhesive from a Chinese manufacturer, however, many users noted that constant maintenance of the cap is required.

- Sealup. Products from Italy are of high quality and ease of use. There is a guarantee seal, which stands out as an advantage, since it is possible to check how tightly closed the package is.

- Abro. One of the few sealants that can be used at negative temperatures - up to -20 degrees.

- Mannol. This option has one of the longest shelf life, however, it is impossible to work with it in a closed room due to the pungent odor.

- Wurth. This German-made retainer is considered to be of the highest quality. Despite its high cost, it is popular.

- Tangit Uni Lock. Manufacturer from Belarus. Specialized gels are available for both plastic and metal.

- Siseal. Anaerobic gels of this brand are often used. Sold in containers of 100 g.

Tips & Tricks

Professional craftsmen share several tips, how to make the sealing of threaded connections as simple and durable as possible.

- Do not be afraid that the uncured sealant will come out from the inside of the pipe. It will not freeze and during the operation of the water supply system it will simply be washed off with water. Anaerobic gels are completely harmless, but it is still best to leave the faucet open for a while so that excess sealant is completely removed.

- When screwing in connections treated with thread sealant, it is not necessary to tighten the threads with wrenches. The maximum effort of the hands will be quite enough, but you really need to wrap it up with full force.

- If the pipe is fragile, then you do not need to try to unwind the treated joint with sealants. Use heating immediately. 170 degrees will be enough.

- If possible, it is best to avoid using temporary sealants. Disassembling the connections will take a lot of time and effort, which does not fully pay off. It is best to resort to the use of thread sealants or flax for temporary use.

For the features of thread sealant, see the following video.

The comment was sent successfully.