Polyurethane sealants for external joints: properties and characteristics

Even the most careful calculations and fit can lead to gaps. And also cracks and cracks appear at different periods of operation of a building structure. This can cause the environment to affect the indoor climate. The solution to these problems is to find a sealant with suitable properties. It is the polyurethane variety that has repeatedly proven its effectiveness in outdoor work.

Properties

The popularity of polyurethane sealant is understandable, since it has many advantages:

- plasticity - even after solidification, it can change: expand or contract with the movement of the fastened elements;

- strength - despite the possibility of changing its shape, in the solidified state it provides a good degree of isolation from cold, water and other weather conditions;

- durability - does not lose its properties over time;

- has a fairly wide range of applications - due to good adhesion to most building materials;

- does not shrink;

- dries quickly - saves time;

- ease of use - the consistency of medium density allows you to economically and accurately fill the cracks without getting dirty, and also not to pause work even at sub-zero temperatures;

- ease of application due to existing fixtures;

- resistant to moisture, significant temperature changes, ultraviolet light, chemicals;

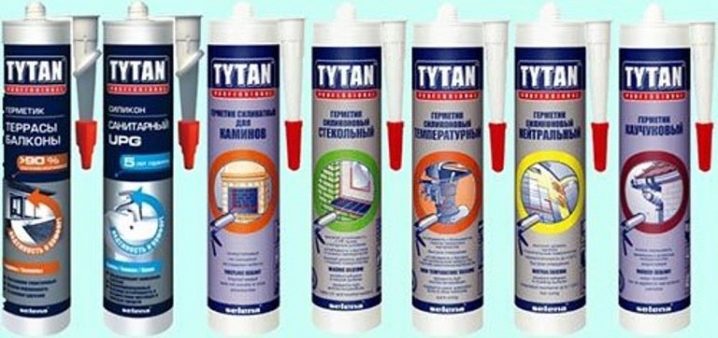

- it can be colorless - does not stand out from the general background - or colored.

The polyurethane sealant has its own peculiarities of use.

- There are application restrictions. The adhesion to some types of plastic will not be strong enough. It is applied with caution to damp building materials if the material is capable of retaining water in itself. In both situations, the situation can be corrected by applying a suitable primer.

- There are temperature limits. In a solidified state, it loses its properties at temperatures below -60 degrees and above +120 degrees Celsius. At temperatures below -10 degrees, it hardens badly.

- The grade of polyurethane sealant should be carefully selected. For example, if the insulated joint is constantly exposed to direct impact, preference should be given to a sealant with a high degree of hardness in the cured form.

Views

The insulating composition can be of different density:

- Low density (15-25) - for general work: with wood, plastics, glass, concrete;

- Average (40) - for joints constantly in contact with moisture, as well as for such hard materials as reinforced concrete;

- High (50-60) - it can handle metal tiles, as well as seams in mechanical engineering.

According to their composition, polyurethane sealants are divided into two types.

- One-component. They are ready-made pasta. Curing occurs naturally due to interaction with air, or rather, moisture contained in it.

- Two-component. The package contains two separate containers with the main substance and the additive, with which the curing process begins.

The advantage of two-component is that they can be used in more severe conditions (at low temperatures) and do not depend on humidity.

The mixing process carries with it additional complications.

- The quality of the sealant depends on the proportions in which the two components are mixed.

- Kneading takes time.

- To obtain the correct mass, homogeneous in consistency and color, you need to spend effort.

The speed and duration of mixing must be sufficient, otherwise the positive properties of the insulation and connection will be partially lost. Therefore, it is better for beginners to choose a ready-made paste, since both types of sealants are practically the same in the field of application.

Where is it used?

The polyurethane sealant is safe and can be used indoors. The frost-resistant and water-resistant polyurethane form is of the greatest value in comparison with other sealants as insulation and joining of external seams.

Polyurethane based sealant can be used for:

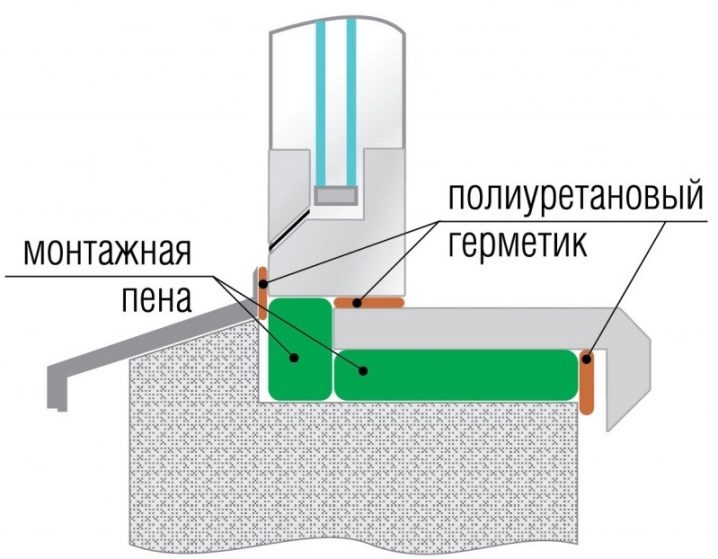

- window structures and door frames, as it allows you to keep warm inside the house and does not allow drafts and cold to penetrate from the outside;

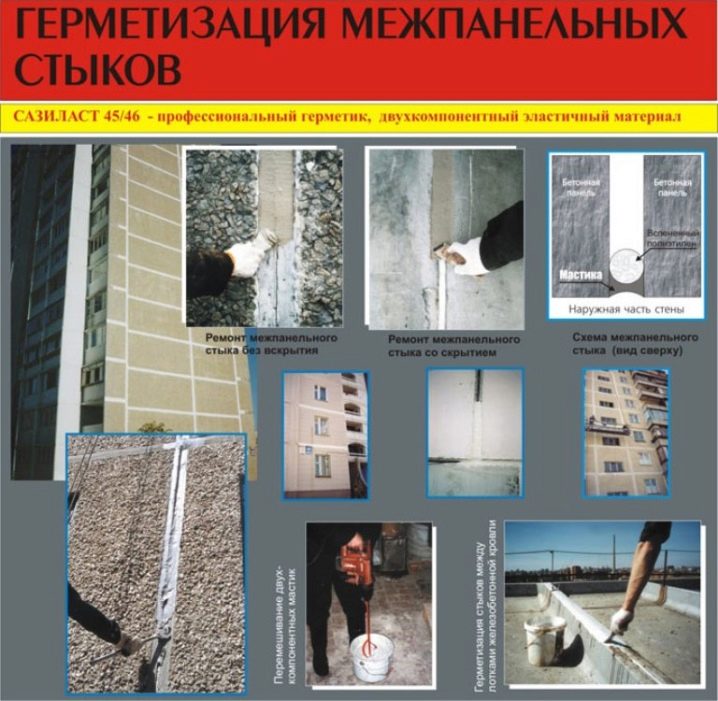

- facades of houses, baths, gazebos, since, in addition to insulation, it creates a fairly strong connection;

- roofs - it is difficult to imagine another such place, which was influenced by natural factors every minute;

- pools, fountains - in this case, the sealant is used for waterproofing;

- metal products, including cars, because it withstands vibration well.

They can glue materials of different density and texture. That is, to combine ceramics and metal, plastic and concrete. Polyurethane material is especially valuable when processing those materials that are prone to expansion or contraction (stone, wood).

To make it clear, let's look at the application of a polyurethane roofing sealant. In this case, the composition treats the joints between the roofing material (even if it is overlapped), the perimeter of the fasteners of heating pipes, gutters, holes for ventilation shafts, and so on. If we are talking about the facade, then most often the longitudinal and transverse seams between block or tile building materials, wooden bars and panels are processed, and their subsequent repair is also carried out.

Application methods

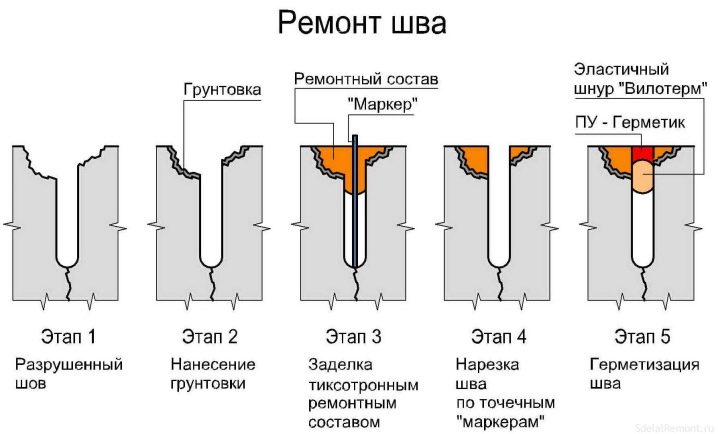

The technique of applying polyurethane sealant to the joint is quite simple.

- It is necessary to clean the recess and the adjacent surface from dust, dirt or old filler. At temperatures below zero, ice and snow must be carefully removed. To make the seam look neat, it is necessary to apply construction tape along the edges of the seam.

- If you are in doubt that the composition will fit well, try applying it to a similar material. And extra training in application will not hurt, since such a sealant sets very quickly. It will be possible to correct the situation only by deleting it and doing all the work again.

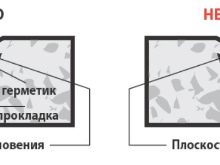

- The method of applying the sealant depends on the joint width. You may need special harnesses or, as they are also called, gaskets, as well as insulating tape. Foamed polyurethane or polyethylene will provide greater thermal insulation. They are placed in the base of a deep and wide seam.

- The mass is applied from above with a spatula. You can use a regular spatula or a special narrow one. If necessary, there can be several layers, the main thing is that each of them does not exceed 4-5 mm. The last layer aligns well.

- Deep and narrow seams are filled with a construction gun. Depending on the scale of work, it can be mechanical, pneumatic or electrical.

- After hardening, the seam can be painted over.

- For safety reasons when working with polyurethane sealant, it is necessary to have a respirator and protective gloves.

For more information on the use of a sealant for sealing various types of joints, see the video.

The comment was sent successfully.