Features of the sealing tape

The modern building materials market offers a wide range of products for sealing and waterproofing. In this variety, a special place is given to the sealing tape, which has a fairly impressive range of applications.

Peculiarities

Moisture can adversely affect buildings, residential and industrial facilities, communications, various mechanisms and parts. Therefore, in the construction and household spheres, it is considered quite important to ensure protection against such impact. Manufacturers are constantly working to create modern and high quality insulation products.

Not so long ago, cement mortars, tow, metal plates, sealants and mastics were used to seal joints, cracks and seams. However, the rational component and manufacturability gradually replaced expensive and labor-intensive materials, which gave way to new universal and inexpensive products that perfectly cope with the task at hand.

Sealing tape is one such multifunctional product that provides reliable insulation. The product is a bitumen-based composite material with the ability to self-adhere, which is the main feature of this product. The mesh structure of the material contributes to the good quality of adhesion of the belt to the working surface.

The products have moisture-proof qualities and are able to take different shapes, so it is very convenient to work with them, and the time required for installation is greatly reduced.

Among the positive properties of the product, one can also highlight a good indicator of the elasticity of raw materials at low temperatures., resistance to the harmful effects of various bacteria, mold and chemicals. The tape is absolutely safe for health and therefore recommended for internal and external use.

Views

Self-adhesive tape is recommended for work in various fields. The demand for products is due to the quality characteristics and ease of use.

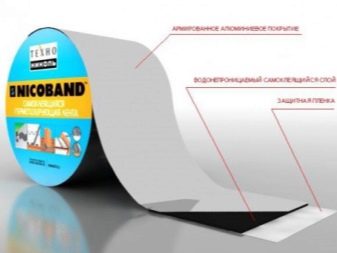

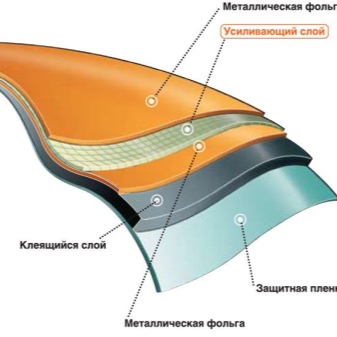

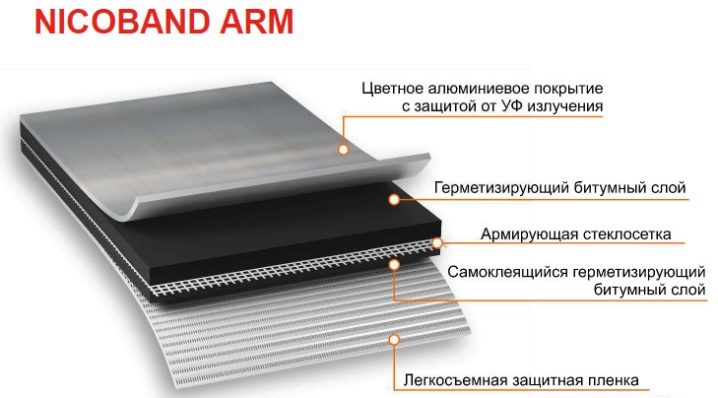

The product is a multi-layer system, the basic elements of which are:

- a waterproof layer of bitumen or rubber with a sticky adhesive mass, which is responsible for fixing the product with a sealed base;

- aluminum foil with high strength indicators, reliably protecting the tape from tearing;

- a special film that is removed before using the tape.

Such a composition makes it possible to perform durable sealing of any structure made from any raw material. Based on the scope of application, the basic composition of the material is sometimes supplemented with layers of other components (for example, to increase the protective or thermal insulation properties).

Depending on the area of use of the tape, there are:

- bilateral;

- one-sided.

The first option assumes the presence of a working surface on both sides of the product, in contrast to the last type.

Also, the presented assortment of sealing tapes is divided into two main types.

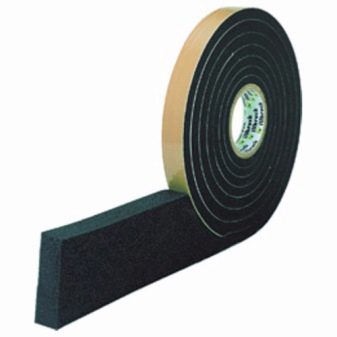

- Products for working with window openings. They are tape products made of polypropylene with an adhesive base, due to which adhesion to the surface of windows and slopes occurs. Products are recommended for moisture protection of structures. Their use eliminates the need to purchase and use plaster and sealant.A type of product for window openings is a vapor-permeable tape, similar in appearance to foam rubber. Its peculiarity lies in the ability to pass the condensate formed in the structure of the polyurethane foam. The products can be used at low temperatures.

- Universal tape. It is made from special bitumen, on which an aluminum layer and a reinforced polyethylene film are applied.

The subtypes of these products are several product options:

- Plaster. Its distinctive feature is the structure of the adhesive layer. It allows you to instantly glue surfaces together. Due to its good adhesion, the material is suitable for concrete, glass, natural stone, plastic and ceramics. Instead of searching for a tape of the desired color, the material can be easily painted in the desired shade. The assortment of this type of finished goods includes four color options.

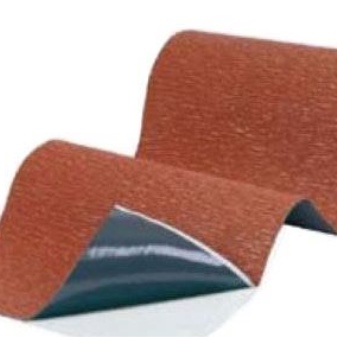

- Ecobit. In this case, a copper or aluminum film is applied to the base layer, the protection of which is provided by polyester. The material forms a high-quality waterproof coating on glass, metal, cement products. Due to this, the products are often used for repairing roofs, pipes, plumbing and sewerage.

- Titanium. It features a polyurethane coating over an anti-condensation polyester base. Such a composition increases wind protection and softens the effects of temperature extremes.

- Masterflax. This material has a specific edge composition that favorably affects the level of sealing. The products are widely used for working with PVC structures, various metal surfaces, concrete bases. Such products are advised to be additionally fixed with nails or glued in two overlap layers.

- Comfort. This material contains a special membrane capable of absorbing moisture, and then, thanks to diffusion, remove it. The main component of the product is special raw materials, which are made from polyester fibers coated with polyurethane. The operational period of the product is about 10 years.

Butyl rubber tapes are also often on sale, which perfectly protect against steam and moisture. Most of them have a double-sided surface for fixing.

Scope of application

Self-adhesive tape is most often in demand in several areas of activity:

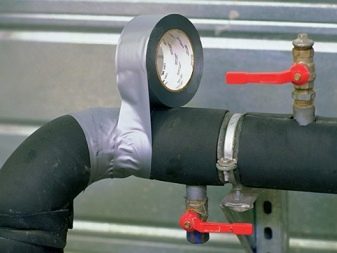

- In construction and utilities - processing of seams between panels of structures, tightness of window and balcony blocks, construction and repair of a rigid roof, as well as fixation of rolled roofing products, installation of sewer and water supply lines, plumbing, installation of ventilation equipment, thermal insulation of the pipeline.

- In transport engineering - work with the cab of freight and light vehicles and repair of ships, sealing the interior of special equipment and cars in order to reduce vibration.

- In the oil and gas direction - provision of protection against corrosion of pipeline seams, insulation repair.

- Domestic use - carrying out various repair work in apartments or private houses (including work related to clothing and plumbing in bathrooms and toilets).

Manufacturers

A number of domestic and foreign companies are manufacturers of sealing tapes. Most of the products have a fairly high level of quality, due to which their popularity among consumers is only growing.

The issue of sealing joints remains the most relevant when it comes to waterproofing devices. Nicoband tapes are produced for this area. In fact, the products are scotch tape with a set of specific positive features. Among them, a thick bituminous layer can be distinguished, which not only glues, but also seals the seams.The products are distinguished by their strength and elasticity, adhesion to all materials, as well as resistance to ultraviolet radiation.

This group of products is represented by three brands: Nicoband, Nicoband Duo, Nicoband Inside. The range of colors of products includes various shades that allow to combine products with roofing, including seam roofing. Nicoband products are recommended for renovation and construction inside and outside buildings. It can be used for sealing joints of various materials, including metal, stone and wood, roofing, sealing pipes and structures made of polycarbonate, metal tiles, ceramic tiles, sealing ventilation.

Elastic tape "Vikar" LT is a self-adhesive non-curing product, amenable to stacking both in length and in width due to the presence of foil in the composition. The product is an excellent assistant in carrying out work with the roof, where it is additionally used to create strength in weak spots of roof waterproofing, in particular in the area of ends and ridge, in places where chimneys and ventilation are exited. The tape can be operated in the temperature range from -60 to +140 C.

"Fum" tape is most often used in the construction of pipelines of houses. It provides thread sealing when installing gas or water supply. Products can be white or transparent. These products are more often sold in reels. Products are presented in three types, which are recommended for different applications based on the technical conditions of future work.

Ecobit from the Italian company Isoltema- is another product used for roofing. The products ensure tightness at the chimney exit points, ventilation and in the area of arrangement of attic window structures. The tape contains a special type of bitumen with polymers of special strength. Copper or aluminum coating is applied to the surface of the product.

It is convenient to work with the tape, performing protection and sealing around the rounded roof elements. The products are absolutely safe and do not contain substances harmful to health. The application technology does not require compliance with the temperature regime. In addition to roofing, the tape is widely used for cement tiles, plastic or glass structures.

Sealing tape SCT 20 is available in black with self-setting mastic. It has excellent ozone and UV resistance. The product is recommended for carrying out repair work in places of damaged insulation of self-supporting insulated wire.

Abris is a high-quality sealant in the form of tapes of various colors. Such products have an anti-adhesive layer on both sides. They are used to join parts made of brick, wood, metal and concrete. The scope of application of the products includes work with roofing, frame structures and the solution of various household tasks. The material is dispensed in rolls.

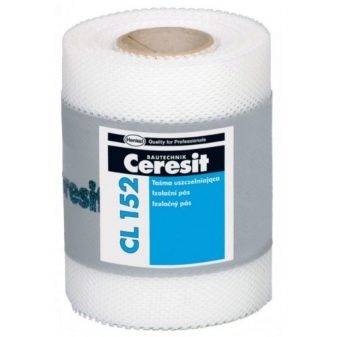

Ceresit CL - tape for sealing joints during the construction of various structures... The products are distinguished by their elasticity and resistance to deformation. Specific features of the material require work with the tape at temperatures from +5 to +30 C.

Tips & Tricks

The use of a sealing tape in the work requires adherence to some recommendations regarding installation:

- First of all, you need to carry out preliminary preparation of the working surface.

- Make sure it is free of grease or oil stains, old paint residues and various contaminants.

- Then the coating, which borders on the seam, must be treated with a waterproofing compound with a small overlap (two to three centimeters).

- The tape is cut from the roll and placed on a layer that should be still wet.

- The resulting coating must be "drowned" into the base with a spatula so that all the air can escape.

- Expansion joints are sealed with tape laid in the form of a loop.

- The joints of materials at the corners are stacked with a slight overlap.

Proper sealing will provide good moisture protection, and the sealing tape will serve as an excellent and reliable material to do the job.

For an overview of the Abris S-LTnp sealing tape (ZGM LLC), see the following video:

The comment was sent successfully.