Sealant: types and scope

Whatever types of construction work are carried out inside the house, sooner or later the time comes when all kinds of joints between tiles, boards or other structures must be sealed. Sealants help to get rid of ugly cracks, give the area a finished look and prevent liquid and / or air droplets from entering the cracks. Today, the building materials market offers a large number of a wide variety of sealants, which differ depending on the composition, the final appearance and the scope of application.

Peculiarities

First you need to figure out what sealants are. For the most part, it is a pasty or heterogeneous viscous mass, created on the basis of polymers or oligomers.

Sealants are designed to protect a variety of surfaces from excess moisture, gaseous substances and household and other contaminants. They fill the gaps and joints between structures: voids near pipes - heating or plumbing, gaps in window frames, the space between the walls and the door frame, ventilation systems - these are just a few of the possibilities for using these products at home.

Most modern compounds, in the quality of which you can be sure, are designed to create a very strong and durable sealing layer. They perfectly interact with wood, stone, brick, concrete, plastic, glass and metal surfaces, they are resistant to high humidity and temperature extremes. By itself, the sealing layer is an elastic coating that is impermeable to water vapor and other vapors.

Such compositions, if you resort to products from trusted manufacturers, are quite reliable. During operation, they are absolutely safe, since they do not emit any hazardous substances.

Appointment

The main task of sealants is to ensure the tightness of seams and joints between elements of various structures.

Sealants are used in many applications. They are able to insulate individual sections of water or heating pipes in order to rid the space of voids or high humidity.

Some types of sealing compounds are necessary for the insulation of premises. There are frequent cases when such compositions are used in facade construction work. They are able to efficiently and easily seal the roof and foundation.

Sealing compounds are applied to bolted, fastening joints, seam elements of structures to provide waterproofing. They are necessary to ensure sealing at the joints of flexible joints. Where other materials can create voids, the composition will simply fill them.

Types and characteristics

There are several main classifications of sealants. In addition to the division into one-component and multicomponent compositions, they can be distinguished by the type of hardening.

- Drying out. They freeze after evaporation of water or the solvent used in them, and also shrink significantly after drying.

- Curing. These compositions become suitable for further work under the influence of water / solvent or air, less often after mixing all the components together. After hardening, these compounds appear rubbery.

- Non-hardening. Such compositions resemble plasticine in appearance.Such mastic hardens only after adding special substances to it.

The most common and important classification considers the properties of various compounds, depending on the substances and compounds they contain.

Silicone

Silicone sealants have the most versatile composition. They are used with equal success in both indoor and outdoor renovations. They have outstanding adhesion to a wide variety of substrates - stone, concrete, metal, glass, wood and ceramics - and cure quickly. In addition, silicone mixtures are quite resistant to aggressive chemicals, tolerate high humidity, as well as active exposure to ultraviolet rays.

There are several more undoubted advantages of silicone sealants. Firstly, it is their high elasticity, due to which such a substance is often used to ensure the tightness of movable joints. Secondly, the service life of silicone sealants is on average 15 to 20 years. Thirdly, these substances are safe for health and environmentally friendly.

The composition of silicone mixtures can be one- or two-component. In any case, the main substance remains an organosilicon polymer, namely silicone rubber. In addition, dyes (usually in decorative varieties), fungicides (their task is to prevent the development of mold), mechanical fillers (they should contribute to improved adhesion) can be found in the composition.

One-component rubber sealants are used in the home. They harden due to moisture in the air. Otherwise, two-component mixtures are used: they are used mainly in industry, since special compositions must be used to harden them.

In turn, one-component silicone sealants, depending on the base, are subdivided into three more subtypes.

- Acidic, as the name implies, contain acetic acid. Therefore, do not be alarmed if, during the hardening process, the substance releases a characteristic acidic odor. Despite this, such formulations, like all silicone mixtures, are safe and environmentally friendly. This type of silicone sealant is suitable for working only with acid-resistant materials, that is, wood, plastic and ceramic products, but they cannot be used with products made of other materials, especially metal.

- One of the components of the neutral sealant can be alcohol or ketoxime, which makes it universally applicable.

- The third type is alkaline sealants. They are made using amines and are rarely used in domestic premises.

There are some other varieties of silicone sealants. Silicate is heat resistant and can withstand temperatures up to 1200 degrees Celsius. Epoxy glue is also suitable for sealing all kinds of cracks, crevices and joints: it is more difficult to apply than analogs, the curing time is about a day, but this glue itself is colorless and transparent.

There is also a self-expanding sealant that begins to expand some time after being applied to the surface. This allows you to fill the gaps as much as possible and ensure complete sealing of the seam.

In addition, these sealants are thermally conductive and allow you to insulate the room if they are used to seal pipes related to heating systems.

Unfortunately, this type of sealing compound is not without some drawbacks. Firstly, the silicone sealant (if initially it turned out to be not the color that the owner needs) cannot be subsequently painted. Secondly, silicone compounds very poorly fit on the old layers of other sealing compounds: in most cases, it will be necessary to completely dismantle the old layer, which can cause certain difficulties.

Many types of sealants become vapor permeable after curing. The vapor-permeable sealant has increased strength, it is more resistant to deformation and adverse weather conditions.

Acrylic

This type of sealant is used mainly for interior work, because it is not flexible enough, although it is quite cheap. These formulations are a blend of several acrylate polymers.

Often, after application, acrylic sealants are coated with acrylic paints or varnish. In addition, the cost of this type of sealing compound is much lower than, for example, silicone.

All sealing compounds based on acrylic polymers are usually divided into waterproof and non-water resistant. The first ones are odorless and absolutely safe for the health of those living in the apartment, but at the same time they do not tolerate deformation very well - their use on surfaces expanding under the influence of temperatures will become disastrous. The ingress of moisture is also bad for this composition.

Waterproof compounds are renowned for their high adhesion to most types of surfaces, including concrete, PVC, drywall and even plaster. In addition, some of the acrylic sealants are flame retardant.

Polyurethane

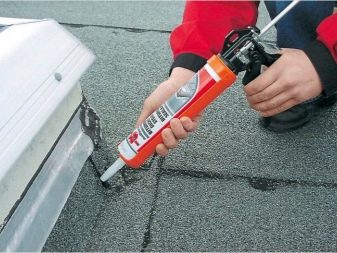

A very elastic, but at the same time resistant to various types of deformation, a variety of sealants, created on the basis of polyurethane and some polymer components. Due to its strength, this material is often used in roofing work or when strengthening the foundation. Like silicone sealants, there are one-component and, less commonly, two-component polyurethane compounds.

This material has excellent adhesion to reinforced concrete, aluminum, plastic, ceramics, wood and stone. Among its advantages - resistance to conditions of high humidity, temperature extremes (from -60 to +80 degrees Celsius), active exposure to ultraviolet radiation.

Although urethane sealants set quickly, they will take about ten hours to fully cure. Since the composition is applied directly from the tube in which it was purchased, or with a special pistol, it will not spread over the surfaces.

Bituminous and rubber

This type of sealing compound is a pasty composition based on an astringent bituminous substance and some additional fillers designed to strengthen the composition and ensure its resistance to hostile environmental factors.

Such compounds are very flexible and heat resistant. They are not afraid of high humidity, exposure to ultraviolet radiation and average mechanical stress. They are easy to work with, and high adhesion characteristics allow you not to clean the surface before applying sealant to it.

Flange sealant can sometimes be distinguished by areas of application: it is used to strengthen joints and seal surfaces with large gaps. Due to its structure, it does not run off vertical surfaces, which gives it an advantage for use on ceilings, for example.

Colors

Different types of sealants, depending on the composition, have different colors and shades. The most diverse in this regard is silicone sealant. Since after application and hardening it cannot be stained, manufacturers try to create their products in different colors. The most common colors are white, beige, red, brown, blue.

If the color does not play a decisive role for the consumer or it is very difficult or completely impossible to choose the desired shade, then existing colorless compositions can be used.

Consumption

It is very important to calculate the amount of sealant required immediately before starting work. This will not only greatly facilitate the process of repair work, but also save money.

For an accurate calculation of the material consumption, it is necessary to know the exact dimensions of the gap, the opening, which will need to be filled with a sealing compound. The width and depth indicators, taken in millimeters, are multiplied, and the result obtained shows the consumption of the sealant per 1 m of the joint in grams.

If it is planned (or known in advance) that the gap that will need to be sealed has a triangular shape, then the product of width and depth is additionally divided by two, the consumption of the mixture in this case is significantly reduced. Typically, such seams are found when processing surfaces perpendicular to each other.

Sealants (in particular silicone) are sold in containers of various shapes and sizes. To find and select a tube of the correct volume, you need to make another simple calculation. Based on how many grams of the composition will be required to fill the gap, the most optimal weight option is selected.

Some manufacturers produce compounds that are sold immediately in tubes created in this way, so that the repairmen only need to cut off the nose, after which they can conveniently begin to fill in the cracks and seams. For some species, you will have to additionally buy a special construction syringe, which will allow you to dose the amount of the composition supplied to the slots.

There is also a spray sealant sprayed directly onto the surface to be sealed, but it is used much less frequently than silicone counterparts.

Manufacturers

On the market you can find a huge number of factories that produce sealants designed for different fields of application. Most manufacturers try to make the same type of sealant, depending on their composition and purpose. Some of the more popular and trusted firms are worth considering.

Acrylic sealant for wood is produced, for example, by the company Remmers... The product itself is called so - Remmers Acryl... This tool, like most acrylic sealants, has high elasticity, it is very plastic, it can withstand low temperatures, and it resists high humidity well. It is also important that the product manufactured by this company is an environmentally friendly composition that is completely safe for human health.

At the heart of Remmers Acryl are acrylic polymers, thanks to which this composition is distinguished by its high elasticity, resistance to adverse weather conditions. No solvents or antiseptics are added to the mixture, which means that the product turns out to be more universal, the scope of its application is significantly increased.

This sealant can be used to seal cracks, seal joints in all kinds of wood structures. This will ensure the preservation of heat in the room, prevent the ingress and accumulation of moisture and dirt in the crevices and seams.

Swiss sealants Sikaflex are renowned for their worldwide renowned Swiss quality. It produces different types of sealants, they can be used in a wide variety of areas. All products of this company are very easy to repair: convenient packaging, ease of use, high adhesion properties to a variety of materials. In addition, Sikaflex products are almost odorless and highly environmentally friendly.

The main types of adhesives and sealants that the company produces Sikaare extremely diverse. These are universal polyurethane sealants - they are used to join parts in places with high loads; bituminous joint sealant (allows to fill cracks and seams in surfaces of concrete and stone, is actively used in roofing and repair work of water supply systems, in particular, gutters), the most neutral silicone sealant (the most common and versatile option in repair work).

Sealing compounds from Sika are distinguished by a relatively wide selection, favorable price and high quality products offered on the market.

Company Permatex is considered the unsurpassed leader in the production of all kinds of adhesives and sealants used for car repair. Despite the rather narrow scope of application, the quality of these products is at a fairly high level. Similar sealants are used in automotive factories and services around the world.

How to choose?

Depending on their composition, sealants differ in both their basic properties and the scope of application.

Acrylic sealants are commonly used to seal joints., cracks and splits in a variety of stone and / or concrete surfaces. Also, this type of sealant is suitable for wood: floorboards, interior door frames and window openings. All kinds of communication pipes, joints formed in bathrooms, kitchens and bathrooms can also be sealed using acrylic compounds.

Silicone sealants are even more widely used. Due to their properties, they are actively used both in indoor work and in external work outside the house. Such compositions are used during door installation. They are used to insulate window frames and balconies. In addition, silicone sealants are used in bath rooms to seal bathtubs, sinks, shower cabins, toilets - they are indispensable for working with water pipes, they allow you to ensure complete tightness, preventing the penetration of odors, water and noise. Silicone sealants can be used when working with cable glands; due to their high adhesion properties, they are also used when working with metal.

Due to their wide temperature tolerance range, silicone sealants are best used for sealing heating systems, chimneys and ventilation systems.

For roofing and roof sealing, sealing joints between corrugated sheets, less deformation and dense bituminous or rubber sealants are used: they allow you to fix roofing material, fix polystyrene foam and other insulating materials. In addition, they are used to seal all kinds of cracks in the foundations of houses, ends, as well as the seams between sandwich panels.

Spray sealants are used to care for vehicle parts (e.g. steering rack, repair cracks in the housing and between the joints of fixed joints).

Also, when choosing a sealant, you should pay attention to its color. After all, if you plan to use a sealing compound in places hidden from the eyes of residents (in sealing plumbing and heating systems, for example), then you can use a colorless compound - in any case, color does not play a special aesthetic role here, because it will simply not be visible. It's another matter if the work will be carried out on visible areas of the surface: in such cases, it is worthwhile to attend to and find the most suitable shade of sealant in color.

This is especially true for silicone sealants, which, after being applied to the surface and hardening, cannot be painted.

Application

Depending on the type of sealant, the individual characteristics and requirements of each of the compositions must be taken into account. For example, before applying any type of silicone sealant, it will be necessary to first degrease and dry the surface thoroughly. Bituminous ones, on the contrary, do not require thorough cleaning of the working surface: they are very elastic, resistant to precipitation and other unfavorable weather conditions, have high adhesion properties, which makes them indispensable for external repair work.

Drying times can also vary considerably. Many sealants are drying compounds that cure and achieve the desired properties after the water or solvent that they contain has evaporated. Some formulations require a special component to help the sealant harden.

Silicone sealants are covered with a film within 10-15 minutes after applying them to the surface, and the rate of their hardening is on average from 2.5 to 4 mm per day. Acrylic sealants, depending on the constituent polymers, can be covered with a primary film from 5 to 20 minutes, the speed of their hardening is much higher and ranges from 2 to 3 mm per hour. Bituminous and rubber sealants harden a little more slowly: when a primary film is formed in the first 12-16 minutes after application, the speed of their hardening is on average 2 mm per hour.

Special construction syringes and pistols will help to use the sealant, where the finished composition is poured, or in some industries, manufacturers immediately release sealing compounds in convenient tubes, in which it is enough to cut a hole and start using them in their repair work.

To properly apply a colored sealant, you need to remember which of them can be applied to a damp surface, and which require careful preliminary drying.

Helpful hints

Before repairing, it is necessary to carefully study all the main types of existing sealants in order to acquire exactly the composition that will be most suitable for the selected type of work.

We must not forget that there is no completely universal sealant for repair, each of the materials has its own unique characteristics and where one type turns out to be ideal, the other will not be able to withstand the loads intended for it and will collapse on its own or damage the surface on which it is applied.

Professionals recommend using bituminous and, less often, silicone sealants for sealing joints in concrete and stone (and in the foundation as a whole). Acrylic is suitable for wooden houses or interior decorations (such as door frames). For roofing work, polyurethane or bitumen sealants are ideal. This will be a particularly good solution for a roof made of metal.

In internal work, it is still more common to use silicone sealants. - they easily seal the seams between plumbing items and walls, they also help in waterproofing and sealing pipes.

To eliminate leaks in plumbing systems and heating pipes, special liquid sealants are often used. When sealing leaks in metal parts, different types of silicone sealants are used, but only the most neutral varieties, since acetic acid containing in their composition will inevitably cause corrosion and destruction of the metal. In addition, such a sealant must not only withstand high water pressure: it must also be resistant to high temperatures.

Many sealants are not only able to withstand temperature extremes, which allows them to be used in various fields. They also easily survive work at subzero temperatures - these are, for example, polyurethane sealants. They can be applied at temperatures down to -10 degrees Celsius.

It is important to pay attention to the temperature range, which the manufacturer of the sealant indicates on the packaging. This will affect the final properties of the product and the place where it will be applied. In addition, it is important to take into account the climatic characteristics of the region in which the sealant is used, if it is used for external work.

For more information on the types and applications of sealants, see the next video.

The comment was sent successfully.