All about wind turbines

To improve living conditions, mankind uses water and various minerals. Recently, alternative energy sources have become popular, especially wind power. Thanks to the latter, people have learned to receive energy supply for both domestic and industrial needs.

What it is?

Due to the fact that the need for energy resources is increasing daily, and the stocks of usual energy carriers are decreasing, the use of alternative energy sources is becoming more and more relevant every day. Recently, scientists and design engineers have been creating new models of wind turbines. The use of the latest technologies improves the quality characteristics of the units and reduces the number of negative aspects in the structures.

A wind generator is a type of technical device that converts kinetic wind energy into electrical energy.

The value and application of the product that these units produce is constantly increasing due to the inexhaustibility of the resources that they use for work.

Where are they used?

Wind generators are used in different places, usually open areas, where the wind potential is greatest. Stations of alternative energy sources are installed in the mountains, in shallow waters, islands and fields. Modern installations can generate electricity even with low wind strength. Due to this possibility, wind generators are used to supply electrical energy to objects of different capacities.

- Stationary a wind farm can provide electricity to a private house or a small industrial facility. During the absence of wind, the energy reserve will be accumulated, and then used from the battery.

- Medium power wind turbines can be used on farms or in houses that are remote from heating networks. In this case, this source of electricity can be used for space heating.

Device and principle of operation

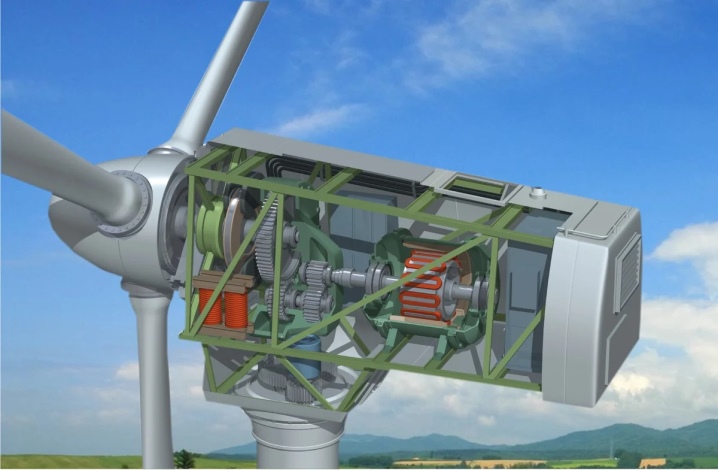

The wind generator is powered by wind power. The design of this device should include the following elements:

- turbine blades or propeller;

- turbine;

- electric generator;

- the axis of the electric generator;

- an inverter, the function of which is the conversion of alternating current into direct current;

- a mechanism that rotates the blades;

- a mechanism that rotates the turbine;

- battery;

- mast;

- rotational motion controller;

- damper;

- wind sensor;

- wind gauge shank;

- gondola and other elements.

The types of generators are different, therefore, the structural elements in them may differ.

Industrial units have a power cabinet, lightning protection, a swing mechanism, a reliable foundation, a device for extinguishing a fire, and telecommunications.

A wind generator is considered to be a device that converts wind energy into electricity. The predecessors of modern units are mills that produce flour from grain. However, the connection diagram and the principle of operation of the generator have practically not changed.

- Thanks to the force of the wind, the blades begin to rotate, the torque of which is transmitted to the generator shaft.

- The rotation of the rotor creates a three-phase alternating current.

- Through the controller, an alternating current is sent to the battery. The battery is necessary in order to create a stable operation of the wind generator. If wind is present, the unit charges the battery.

- To protect against a hurricane in the wind power generation system, there are elements to divert the wind wheel from the wind. This happens by folding the tail or braking the wheel using an electric brake.

- To recharge the battery, you will need to install a controller. The functions of the latter include tracking the charging of the battery to prevent its breakdown. If necessary, this device can dump excess energy onto the ballast.

- Batteries have a constant low voltage, but it should reach the consumer with a power of 220 volts. For this reason, inverters are installed in wind generators. The latter are capable of converting alternating current into direct current, increasing its power indicator to 220 volts. If the inverter is not installed, it will be necessary to use only those devices that are rated for low voltage.

- The transformed current is sent to the consumer to power heating batteries, room lighting, and household appliances.

There are additional elements in the design of industrial wind generators, thanks to which the devices operate in an autonomous mode.

Types, their advantages and disadvantages

The classification of wind farms is based on the following criteria.

- Number of blades. Currently on sale you can find a single-bladed, low-bladed, multi-bladed windmill. The fewer blades a generator has, the higher its engine speed will be.

- Indicator of rated power. Household stations generate up to 15 kW, semi-industrial - up to 100, and industrial - more than 100 kW.

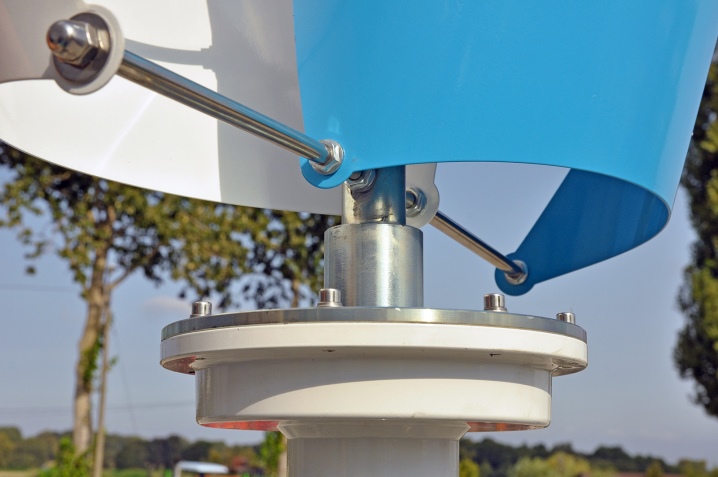

- Axis direction. Wind turbines can be both vertical and horizontal, each type has its pros and cons.

Those wishing to acquire an alternative source of energy can buy a wind generator with a rotor, kinetic, vortex, sail, mobile.

There is also a classification of wind power generators according to their location. Today, there are 3 types of units.

- Terrestrial. Such windmills are considered the most common; they are mounted on hills, elevations, sites prepared in advance. The installation of such installations is carried out using expensive equipment, since the structural elements must be fixed at a high height.

- Coastal stations are being built in the coastal part of the sea and ocean. The operation of the generator is influenced by the sea breeze, due to which the rotary device produces energy around the clock.

- Offshore. Wind turbines of this type are installed at sea, usually at a distance of about 10 meters from the shore. Such devices generate energy from the regular offshore wind. Subsequently, the energy goes to the shore through a special cable.

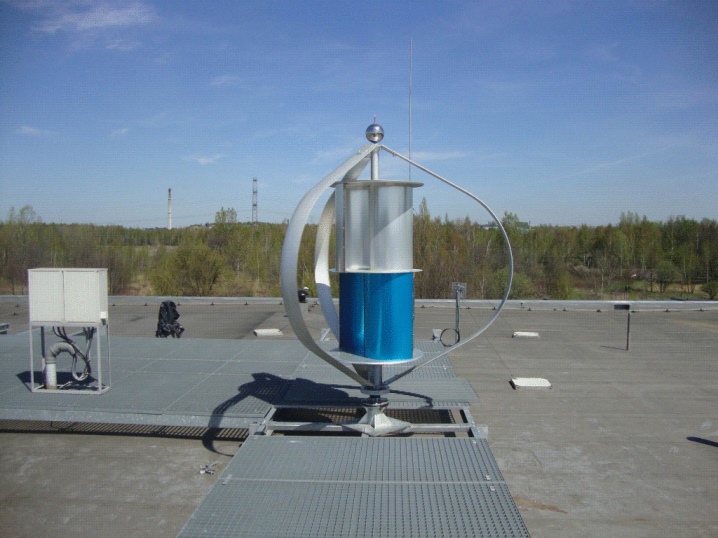

Vertical

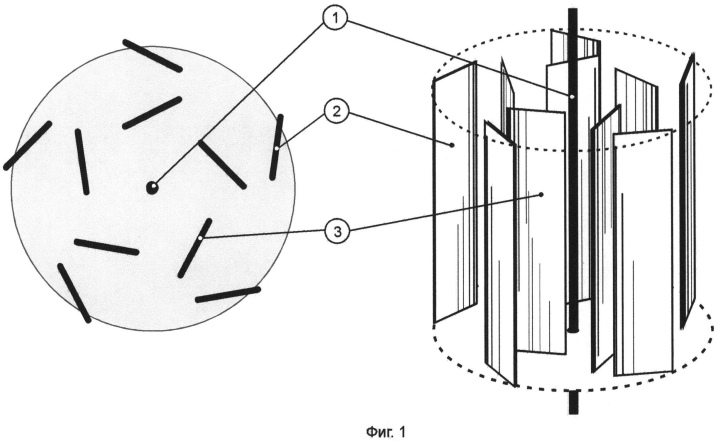

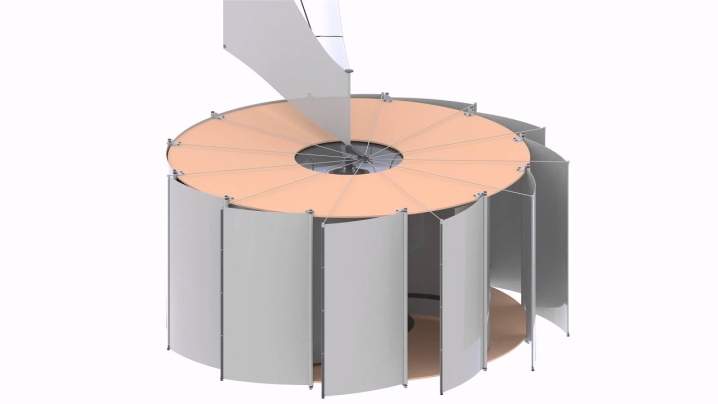

Vertical wind turbines are characterized by a vertical axis of rotation relative to the ground. This device, in turn, is divided into 3 types.

- With a Savounis rotor. The structure includes several semi-cylindrical elements. The rotation of the unit axis occurs constantly and does not depend on the strength and direction of the wind. The advantages of this generator include a high level of manufacturability, high-quality starting torque, as well as the ability to function even with a slight wind force. Disadvantages of the device: low-efficiency operation of the blades, the need for a large amount of materials in the manufacturing process.

- With Darrieus rotor. Several blades are located on the rotational axis of the device, which together have the form of a strip.The advantages of the generator are considered to be the absence of the need to focus on the air flow, the absence of difficulties in the manufacturing process, and simple and convenient maintenance. The disadvantages of the unit are low efficiency, short overhaul cycle, and poor self-starting.

- With helical rotor. The wind generator of this type is a modification of the previous version. Its advantages lie in a long period of operation and a low load on mechanisms and support units. The disadvantages of the unit are the high cost of the structure, the difficult and complex process of manufacturing the blades.

Horizontal

The axis of the horizontal rotor in this device is parallel to the earth's surface. They are single-bladed, double-bladed, three-bladed, and also multi-bladed, in which the number of blades reaches 50 pieces. The advantages of this type of wind generator are high efficiency. The disadvantages of the unit are as follows:

- the need for orientation according to the direction of air flows;

- the need for the installation of high structures - the higher the installation, the more powerful it will be;

- the need for a foundation for the subsequent installation of the mast (this contributes to an increase in the cost of the process);

- high noise level;

- dangers to birds flying by.

Vane

Blade power generators have the form of a propeller. In this case, the blades receive the energy of the air flow and process it into rotary motion.

The configuration of these elements has a direct impact on the efficiency of the wind turbine.

Horizontal wind turbines have impellers with blades, of which there may be a certain number. Usually there are 3 of them. Depending on the number of blades, the power of the device can either increase or decrease. A clear advantage of this type of wind turbine is the uniform distribution of loads on the thrust bearing. The disadvantage of the unit is that the installation of such a structure requires a lot of additional materials and labor costs.

Turbine

Wind turbine generators are currently considered the most efficient. The reason for this is the optimal combination of blade areas with their configuration. The advantages of the bladeless design include a high level of efficiency, low noise, which is caused by the small dimensions of the device. In addition, these units do not collapse in strong winds and do not pose a danger to others and birds.

A turbine-type windmill is used in cities and towns, with its help it is possible to provide a private house and a summer cottage with lighting. There are practically no drawbacks to such a generator.

The downside of the wind turbine is the need for stabilizing components of the structure.

Main characteristics

The main advantageous characteristics of wind generators are the following:

- environmental safety - the operation of the installations does not harm the environment and living organisms;

- lack of complexity in the design;

- ease of use and management;

- independence from electrical networks.

Among the disadvantages of these devices, experts distinguish the following:

- high cost;

- the opportunity to pay off only after 5 years;

- low efficiency, low power;

- the need for expensive equipment.

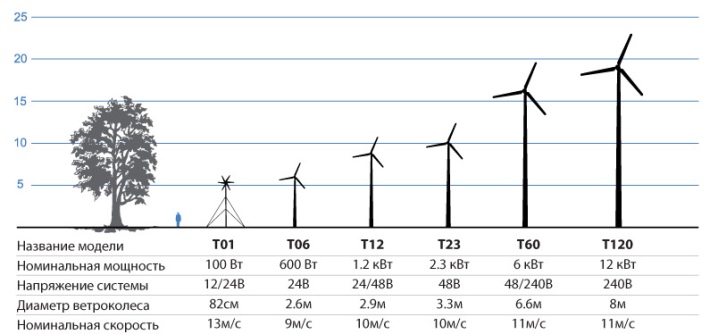

Dimensions (edit)

Devices for generating energy from wind can be of different sizes. Their power depends on the size of the wind wheel, the height of the mast and the wind speed. The largest unit has a column 135 m long, while its rotor diameter is 127 m. Thus, its total height reaches 198 meters. Large wind turbines with a large height and long blades are suitable for providing energy to small industrial enterprises, farms. More compact models can be installed at home or in the country.

Currently, they are producing a marching type of windmill with blades in diameter from 0.75 and 60 meters. According to experts, the dimensions of the generator should not be grandiose, since a small portable installation is suitable for generating a small amount of energy. The smallest model of the unit is 0.4 meters high and weighs less than 2 kilograms.

Manufacturers

Today, the production of wind turbines is established in many countries of the world. On the market you can find Russian-made models and units from China. Of the domestic manufacturers, the most popular are the following firms:

- "Wind-Light";

- Rkraft;

- SKB Iskra;

- Sapsan-Energia;

- "Wind Energy".

Manufacturers can make wind turbines according to the personal preference of the customer. Also, manufacturers often have a service for calculating and designing wind farms.

Foreign manufacturers of power generators are also very popular:

- Goldwind - China;

- Vestas - Denmark;

- Gamesa - Spain;

- Suzion - India;

- GE Energy - USA;

- Siemens, Enercon - Germany.

According to consumer reviews, foreign-made devices are of high quality, since they are made using the latest equipment.

However, it is worth remembering that the use of such wind generators implies the use of expensive repairs, as well as spare parts, which are almost impossible to find in domestic stores. The cost of power generation units usually depends on the design features, capacity and manufacturer.

How to choose?

To choose the right wind generator for a summer cottage or home, you need to take into account the following.

- Calculation of the power of installed electrical appliances that will be connected in the room.

- The power of the future unit, taking into account the safety factor. The latter will not allow overloading the generator in a peak situation.

- The climate of the territory. Precipitation has a negative impact on the performance of the device.

- Equipment efficiency, which is considered one of the most important indicators.

- Noise indicators that characterize the wind turbine during operation.

In addition to all of the above, the consumer should evaluate all the parameters of the installation, as well as read the reviews about it.

Ways to improve work efficiency

To increase the efficiency of the operation of the wind generator, it will be necessary to change its operating capabilities and characteristics in a positive direction. First, it is worthwhile to increase the efficiency of the impeller sensitivity to relatively weak and unstable wind.

To translate the idea into reality, it is recommended to use a "petal sail".

This is a kind of one-sided membrane for air flow, which freely passes the wind in one direction. The membrane is an impermeable barrier to the movement of air masses in the opposite direction.

Another method of increasing the efficiency of a wind turbine is the use of diffusers or protective caps, which cut off the flow from the opposing surface. Each of the options has both advantages and disadvantages. However, they are in any case more effective than the traditional model.

DIY construction

A wind generator is expensive. If you want to install it on your territory, it is worth considering the following points:

- availability of suitable terrain;

- prevalence of frequent and strong winds;

- lack of other alternative energy sources.

Otherwise, the wind farm will not give the expected result. Since the demand for alternative energy is increasing every year, and the purchase of a wind turbine is a tangible blow to the family budget, you can try to make a unit with your own hands with subsequent installation. The manufacture of a wind turbine can be based on neodymium magnets, a gearbox, blades and their absence.

The wind turbine has a lot of advantages. Therefore, with a great desire and the presence of elementary designer skills, almost any craftsman can build a station to generate electricity on his site. The simplest version of the device is considered to be a wind turbine with a vertical axis. The latter does not require support and a high mast, and the installation procedure is characterized by simplicity and speed.

To create a wind generator, you will need to prepare all the necessary elements and fix the module in the chosen place. As part of a homemade vertical energy generator, the presence of such elements is considered mandatory:

- rotor;

- blades;

- axial mast;

- stator;

- battery;

- inverter;

- controller.

The blades can be made of lightweight resilient plastic, as other materials can be damaged and deformed under the influence of high loads. First of all, 4 equal parts must be cut from PVC pipes. After that, you need to cut out a couple of semicircular fragments from the tin and fix them along the edges of the pipes. In this case, the radius of the blade part should be 69 cm. In this case, the height of the blade will reach 70 cm.

To assemble the rotor system, you need to take 6 neodymium magnets, 2 ferrite discs with a diameter of 23 cm, glue for bonding. Magnets should be placed on the first disc, taking into account an angle of 60 degrees and a diameter of 16.5 cm. According to the same scheme, the second disc is assembled, and the magnets are poured with glue. For the stator, you need to prepare 9 coils, on each of which you wind 60 turns of copper wiring with a diameter of 1 mm. Soldering must be carried out in the following sequence:

- the beginning of the first coil with the end of the fourth;

- the beginning of the fourth coil with the end of the seventh.

The second phase is assembled in a similar way. Next, a form is made from a plywood sheet, the bottom of which is covered with fiberglass. Phases from soldered coils are mounted on top. The structure is filled with glue and left for several days to glue all the parts. After that, you can start connecting the individual elements of the wind generator into a single whole.

To assemble the structure in the upper rotor, 4 holes for the studs should be made. The lower rotor is installed with magnets upwards on the bracket. After that, you need to place the stator with the holes required for mounting the bracket. The pins should be resting on the aluminum plate, then cover with the second rotor with the magnets down.

Using a wrench, it is necessary to rotate the pins so that the rotor drops down evenly and without jerks. When the right place is taken, it is worth unscrewing the studs and removing the aluminum plates. At the end of the work, the structure must be fixed with nuts and not tightly tightened.

A strong metal pipe with a length of 4 to 5 meters is suitable as a mast. A pre-assembled generator is screwed to it. After that, the frame with the blades is fixed to the generator, and the mast structure is installed on the platform, which is prepared in advance. The position of the system is fixed with a brace.

The connection of the power supply to the wind turbine occurs sequentially. The controller must take a resource from the generator and convert the alternating current to direct current.

The following video provides an overview of a homemade windmill.

The comment was sent successfully.