Choosing a lawn mower engine

If the engine in the mower is out of order, and this fact is beyond doubt, it is time to replace the engine with a new one. You will not be able to continue working until the motor has been replaced. And in order to change the engine yourself, find out what type and type it is on this device.

Types of motors for mowers

Nowadays, motorized lawn mowers are widely used. Electric and gasoline engines are used on machines of this type and class. Among the former, synchronous and asynchronous, collector and brushless, and even stepper motors are widespread here. Among the latter are two- and four-stroke.

Gasoline

A gasoline engine converts the internal energy of the fuel into thermal energy, and then into mechanical energy. The continuity of the gas engine is ensured by a constant and slow supply of fuel and oil to the combustion chamber (carburetor), where they mix with air and ignite from the sparks generated by the spark plugs. The number of cylinders in the petrol engine of the lawn mower is only 1. This distinguishes lawn mowers from cars that use 4-8-cylinder engines. The fact is that one cylinder is enough not only to mow the grass, but, for example, to ride a snowmobile alone.

On brushcutters and mototrimmers, a two-stroke or four-stroke engine is used. The second of them is the most effective, it is easy to refuel - gasoline and oil are poured into different tanks separately. For the first, it is necessary to mix gasoline with oil and pour the resulting fuel into a common tank. The two-stroke engine does not burn it to the end - some unburned gasoline remains in the exhaust.

For gasoline engines, power is not limited to two kilowatts. If you translate the horsepower of the most powerful lawn mower into kilowatts, then the power will increase to 5 or more kilowatts. The petrol engine can work without problems for an hour or more, without stopping for a break. They also pay for the increased power with noise - not 30-45 decibels, but 55-80.

For a long mowing on gasoline, you need headphones that muffle the roar of the engine.

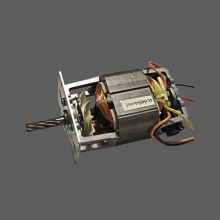

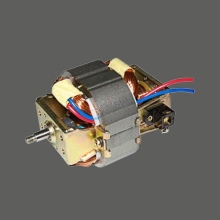

Features of electric motors

An electric motor converts electrical energy into mechanical energy, delivering torque. Through the gearbox, this kinetic energy is transferred to the knives or a drum with line (or cord), which cuts the grass.

The electric motor itself is economical. There is no need to choose whether to burn gasoline, a liter of which in 2019 is selected in Russia to 50 rubles, or to consume 10-15 kilowatts from the outlet for the same money. And the price of an electric motor equivalent to the same 5 "horses" is much lower. The electric motor can be operated from an outlet and from a battery. It is ideal for owners of small summer cottages with a plot of no more than a few hundred square meters.

The electric motor must be turned off every 15-20 minutes for at least 20 minutes - this will allow it to cool down. It heats up much faster under load from the mowed grass than without it. If you ignore the breaks, then such a motor will not work for a long time. Overheating motor windings will gradually burn out.

Synchronous motor

The name of this type of motor speaks for itself, and the principle of operation is as follows: the rotating structure - the rotor - exactly gets into the oscillations of the induction field generated by the windings of the stator part. The field speed is the same as the rotor speed.

The power consumption of a synchronous motor is more than a kilowatt, which is explained by its complicated circuit. The rotor winding is designed for a single phase. The winding itself is powered by a direct current source, and sliding contacts - rings and brushes - are connected to it. Even with a significant load on the rotor axis, this motor does not reduce the rotor speed (number of revolutions per minute).

In lawn mowers, the motor shaft is positioned vertically - this allows it to transmit maximum torque through a gearbox or belt drive to the working drum.

Starting, the synchronous motor does not immediately switch from asynchronous to its normal mode, but it justifies its real characteristics by 100 percent.

Asynchronous vertical shaft motor

Asynchronous motor, in comparison with the previous type, is much simpler. The rotor is also equipped with external excitation windings. In general, the operation of the motor is not tied to changes in the induction field generated by the stator. The rotor speed does not coincide with the speed of the magnetic field change.

The advantage of an asynchronous motor with a vertical shaft is the absence of a gearbox or belt drive. Knives or a drum with a line are attached to an axle rigidly connected to the motor rotor.

Asynchronous disadvantages:

- the engine itself slows down with a significant increase in load;

- its power and efficiency are noticeably lower than that of a synchronous motor.

The speed control when mowing grass with an asynchronous motor occurs not only with the help of natural deceleration under load, but also with the help of an electronic divider that produces different supply voltages. Some models have a stepless knob or multi-position switch.

This helps to extend the running time of the electric lawnmower where the grass is sparse and high revs are not needed.

What to choose?

For large - 20-60 acres - a lawn mower is suitable for gasoline or diesel fuel, and not electricity. If the choice still fell on an electric mower, lawn mowers with an asynchronous engine are cheaper than similar models in which a synchronous motor is built. Asynchronous lawn mowers are mainly equipped with direct drive.

The most popular electric mowers of the following companies:

- Honda;

- Briggs & Stratton;

- Lifan;

- DDE;

- Patriot;

- Mitsubishi;

- Caiman;

- Champion.

So, Honda engines expensive - the motor itself costs from 5 to 30 thousand rubles, depending on the power. American Briggs & Stratton engines, which are not inferior to engines from the same "Honda", are installed in devices from Snapper, Ferris, Simplicity and Murray.

For example, if you are changing the motor on a lawnmower that uses a direct drive asynchronous motor, check to see if there are models compatible with yours that use a similar motor and drive. This method is good when your model is already 5 or more years old, it has been discontinued. You can try to restore your old device without purchasing a new one. Self-propelled lawn mowers require more powerful engines than non-self-propelled ones - part of the energy is spent on the fact that the lawn mower “drives itself” during operation.

Possible problems and motor replacement

For example, instead of the standard 3000 rpm, the engine gives, say, 2200, 1700 - such a decrease is gradual. Brush DC motors with almost worn brushes often suffer from this disadvantage. The fact is that the graphite rod on the brush is slowly but surely abraded.

Finally the exposed terminal, displaced by the expanding brush spring, spoils the copper tracks on the rotor - one of the ends of one or another winding fits to each of the tracks. The motor stalls more and more often and does not start even after it has completely cooled down. In order for the motor to work properly, users change the brushes for new ones.

Buy a model of a mower with a brushless motor, the resource of which is tens and hundreds of times longer.

The main reasons for engine failure:

- collision of a car with an abandoned unit;

- storing the mower in a damp, dirty room or outdoors in winter, in the rain;

- untimely cleaning and lubrication of the engine and drive;

- long - more than 20 minutes - work without interruption;

- debris and stones on the territory, bumpiness of the soil;

- oxidation of contacts, wear of brushes and other minor damage to the motor.

In the service center for the repair of electrical and motor equipment, the masters will replace the motor. They will pick up the exact same or compatible one from a different model.

For information on how to choose an engine for a lawn mower, see the video.

The comment was sent successfully.