Discs for petrol cutters: what are they, how to select and install?

Brushcutter knives are an irreplaceable thing. It is enough to choose a suitable one, and you can use them to mow huge areas of grass. Of course, the variety of knives complicates the task of selecting them somewhat. To understand which cutting element is needed, you need to familiarize yourself with the main ones. You should also find out in advance about the correct sharpening and use of knives.

Species overview

For brushcutters, preference should be given to special knives. They allow you to cut taller, tougher grass than line. In addition, the knife is suitable even for pruning young bushes.

There are many types of discs that differ in the cutting edge, shape and material from which they are made.

Each species has its own characteristics.

By making cutting edges

Teeth:

- with two teeth - for young soft grass, lawns;

- with three teeth - for young grass, dead wood, weeds;

- with four teeth - for tough grass and young tree shoots;

- with eight teeth mow the grass without too much chopping;

- with 24 teeth - for hard and dry grass, shrubs, thin trees;

- with 40 or more teeth - for mowing any grass, bushes, trees;

- from 80 and more - for professional brushcutters.

Blades:

- with two - for soft and low braids;

- with three - for mowing weeds;

- with four or more - for mowing grass for hay.

By form

By shape, knives with disc blades and several blades are distinguished, which are at a certain distance from each other. The shape of the blades may also vary. It should be noted that this does not affect either the speed or the quality of the brushcutter's work.

Currently, manufacturers began to offer, in addition to traditional shapes, also triangular, rectangular and trapezoidal.

By material

The disc for the brushcutter can be made of metal or plastic. It should be clarified that plastic blades should be preferred for electric brushcutters. They fit perfectly with the curved shaft of this tool, which doesn't separate too much between the work area and the mower's legs. Plastic knives are good at mowing overgrown dry grass, for example, nettle or burdock trunks.

The metal knives are only suitable for the petrol trimmer. This is due to the flat bar that moves the disc away from the feet to a safe distance. Specially shaped handles also contribute to safety. When hitting a hard object, part of the impact is absorbed by the engine clutch. Iron knives are suitable for mowing grass from large areas, weeds, bushes, young trees.

Manufacturers overview

There are a lot of manufacturers of discs for brushcutters. It is worth familiarizing yourself with the most popular among them. For example, the Bosch brand is known for its knives with two and three blades... The peculiarity of the knives of this company is that each of the blades can be replaced separately from the others.

Another firm known for its bladed knives is Shark. The advantage of the design is that the blades are fixed relative to each other at an angle of 120 degrees. As a result, it is easy to adjust each of the blades, which is convenient for different vegetation. Another feature of knives from this manufacturer is their low weight.

Husqvarna is also known for its multi-tooth knives., especially with hay knives. Ideal for dense and dense grass.Of the minuses, it is worth noting the large weight of the discs and the fact that you cannot turn the knife over if one side of it is sharpened.

Inforce knives do a good job with undergrowth and branches. In practice, the metal from which the cutting elements are made shows itself to be very durable. The only thing is that in some models, victorious solders are erased very quickly.

Knives often get positive reviews by Maruyama... They are characterized as very strong and durable.

The discs cope equally well with different types of grass, as well as with shrubs and trees.

Rezer discs are excellent at mowing grass, weeds, branches. The teeth can withstand well even cutting down trees with a thickness of 6 centimeters or more. However, they have a drawback in the form of winding the grass on the shaft.

Patriot produces quality knives. Users note that if you choose the right disk for a specific job, then it will serve for a long time and amaze with its performance. Knives from this manufacturer are very easy to sharpen yourself.

How to choose?

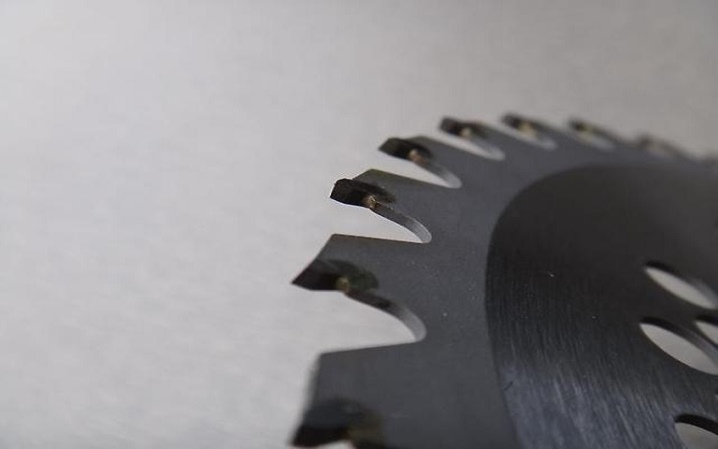

When choosing a knife for a mower, there are many points to pay attention to. For example, metal toothed discs are most often circular in shape. Teeth can differ in shape, appearance, size. For small trees and thick grass, it is better to give preference to discs with a large number of teeth.

It is worth noting such an advantage of milling discs for brushcutters, as a quick set of revolutions. However, a high moment of inertia does not have the best effect on the drive of the machine. For dense mowing, for high, as well as for small coarse grass and bushes, it is better to choose circles with 40 or more teeth and perforation. They are able not to chop up vegetation, and at the same time it will practically not wrap around a circle. If the number of teeth is more than 60, then you can safely mow grass and trees with a trunk thickness of up to 7 cm.

Solid discs and discs without holes are very heavy, so they should be chosen for powerful trimmers (over 40 cm3). At the same time, they are convenient for mowing rare grass, dead wood, and they are also suitable for mowing with different densities.

Victory-tipped discs should be chosen for mowing plants near obstacles. If you need to mow grass for hay, then steel knives with a large number of teeth with an even sharpening should be preferred. Solid discs with 16 to 32 teeth cut plants with thick stems well.

For low power trimmers, paddle discs with a minimum moment of inertia are better suited. The fewer the blades, the more the tool will chop the grass. Thus, discs with two blades are most often used for mowing uniform grass. The main advantage of this species is that it throws cut plants to the side.

When harvesting hay, it is recommended to choose knives with four blades so that the grass is not chopped up.

The thickness of the blades is also important when choosing. Discs can be stamped or forged. The former are distinguished by a low price, but at the same time they can be severely damaged when faced with an obstacle. As for forged discs, they do not chip and cut when colliding with hard objects.

For electric trimmers, choose only plastic blades. Their low weight will not put unnecessary stress on the engine. Soft plastic allows the knives to not break when facing an obstacle, but simply bend or deform slightly. The use of such cutting elements is recommended for cutting thick, soft grass.

How to sharpen and deliver?

With constant use, the gas cutter will sooner or later begin to need regular maintenance. One of the important points is the timely sharpening of knives. The metal disc can, of course, work in a dull state, but it cannot be used. This leads to a decrease in performance, overheating of the engine, and wear of the gearbox. Sharpening the teeth or blades is a snap, but you can simply install new knives if you like.

- First of all, the knife is removed from the device. It is not recommended to sharpen directly on the brushcutter, as it is unsafe.

- Next, you need to inspect the cutting element for chips, cracks, damage. If they are, then you will need to install a new disk.

- You can use a file, sharpener or grinder to sharpen knives. The safest tool is a file that even a beginner can handle. For sharpening, the knife is placed in a vice, and then manually processed at an angle of 30 degrees. This method is considered to be of the highest quality.

When using a grinder, it is important not to overheat the metal, otherwise the disc will quickly become unusable. A grinder with a thin abrasive wheel is suitable for sharpening discs with many teeth.

- Once sharpening is complete, the blade can be reattached to the trimmer and tested to see how well the tool is performing. Do not handle the sharp parts of the knife to avoid injury.

Over time, the knife will wear out and should be replaced. Fitting a new disc to the trimmer is a snap. This procedure takes no more than 5 minutes if you follow simple instructions.

- First you need to remove the protective cover, but on some models it may remain. For example, metal covers cannot be removed from the brushcutter.

- Next, you should take a key with six faces (hexagon) and use it to block the gearbox. The hole for blocking must be looked for from the side or from the end.

- After that, it is necessary to unscrew the mowing head from the brushcutter.

- Then a disc will be installed in its place. It should be noted that the inner diameter of the knife must be completely located in the groove reserved for this. The face of the nozzle should be with the letters facing up.

- Now you need to fix the disc with a special washer and screw the fastening nut counterclockwise. Before doing this, it is necessary to block the gearbox shaft.

- The last step is to install a plastic protective casing.

How to mow the grass correctly?

Mowing the grass begins with the start of the petrol cutter. It is best to do this on the ground to make it safer. Also, before working with a brushcutter, it is advisable to put on an unloading belt, which can be on ties or a carabiner. After starting, the tool is attached to the belt and you can start working.

An important point before mowing is belt balancing. Correctly, if the load on the operator's hands is minimal. The mower only moves the device with his hands, otherwise he will get too tired.

The main weight should rest on the shoulders of the worker.

The tool must be smoothly moved to the right and left. In this case, the trimmer should be located at the same distance from the ground. It is important that the operator moves slowly ("duck steps").

It is not easy for beginners to keep the momentum at the same level. Depending on the density of the grass, the speed should vary. For example, cutting young grass does not require much power at all.

It is important to feel the work of the unit. After all, if the brushcutter cannot cope with the grass, then it is necessary to increase the speed. However, continuous operation at high speeds will quickly wear out the tool.

Experts recommend that when mowing with a petrol trimmer in one direction, increase the speed, and when moving to the other, release the gas and take a step forward. This method works especially well if you need to lay the grass in swaths.

For information on what disks for petrol cutters are, see the next video.

I disagree about the constant "twitching" of the throttle.

It is correct to constantly gas and release gas - this is the wear of the clutch. Took slightly above average revs and mows slowly.

The comment was sent successfully.