Features of calculating aerated concrete at home

Aerated concrete is a widely demanded material. Its advantages over other options are undeniable. It is very important to calculate the required volume in order to prevent errors.

Initial data

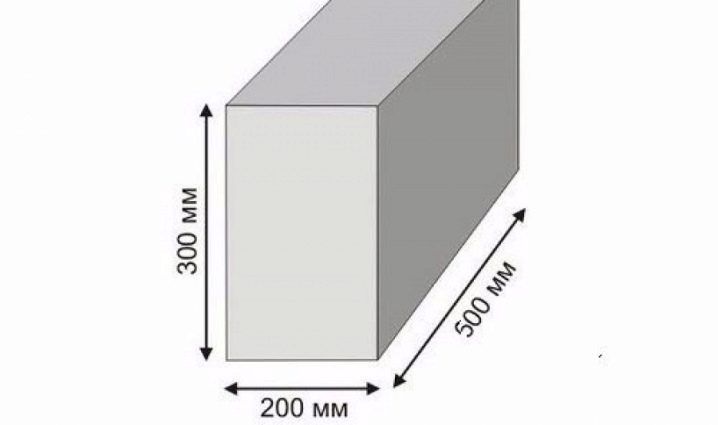

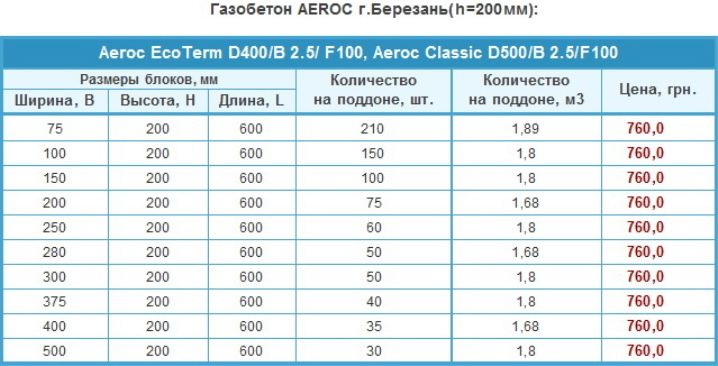

The calculation of the number of GAS BLOCKS is carried out taking into account the parameters of the construction of the house and the geometry of the elements. Traders measure their goods in cubic meters. Therefore, it is also recommended to carry out calculations in meters. The purpose of the block is determined depending on the dimensions. Let the masonry element (gas block) be taken for the calculation with a size of 0.4x0.625x0.25 m.

Minimum wall thickness

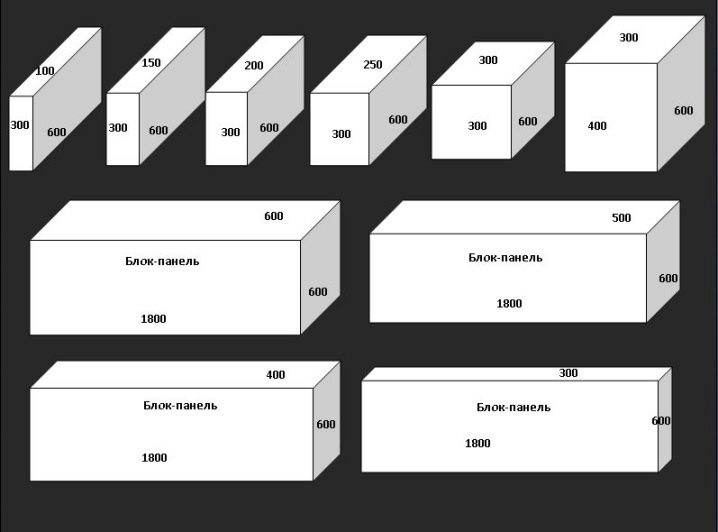

The smallest wall thickness when using serial aerated concrete blocks is 10 cm. In practice, large elements are also used. The outer walls of houses are usually erected from aerated concrete parts with a size of 0.4 m. Smaller details are used in the design of partitions inside the building. It does not depend on the climatic characteristics of the area.

Quantity and weight

One cubic meter

Begin by determining the volume of 1 piece of aerated concrete block. It is calculated by multiplying all three main indicators. For example, 40x62.5x25 cm as a result give 0.0625 cubic meters. m. for 1 pc. the largest size. Now you need to calculate how much 1: 0.0625 will be. The conclusion is logical: 16 aerated concrete blocks are placed in 1 cube.

First, you need to decide exactly on the required values. If blocks of 200x300x600 mm are used, the situation changes. The volume of a single block will be 0.036 cubic meters. m. When using structures measuring 250x300x600 mm, the total volume reaches 0.045 cubic meters. m. That is, 1 m3 includes 27 and 22 blocks, respectively.

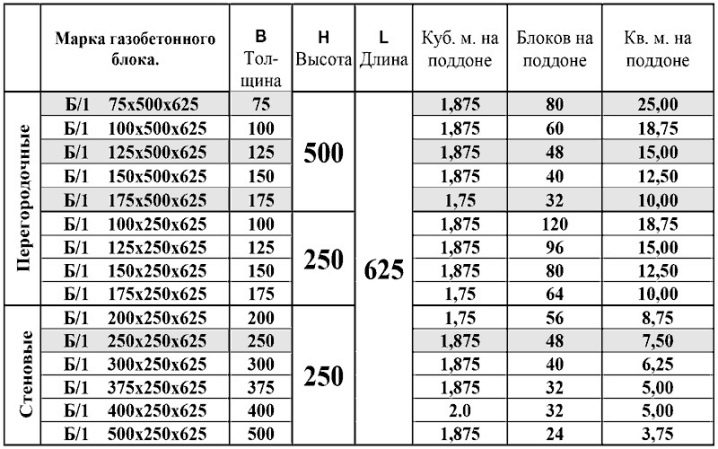

In the pallet

It is not worth recalculating the volume per pallet right away, as well as calculating how much one block weighs. One must first correct for 5 and sometimes 10% of the excess that must be added. The fact is that in real construction there can always be an overrun of parts. It is also worth remembering about manufacturing defects: it happens even on first-class lines.

A full-fledged calculation also involves the determination of the loads that will act on the foundation. These loads are calculated in accordance with the mass of the building material in a given volume.

There are 4 main categories of products, which differ in the type of fillers:

- especially light and extremely porous (about 500 kg per 1 cubic meter);

- light (shell rock or expanded clay is used for filling, density up to 1800 kg per 1 m3);

- heavy (from 1800 to 2500 kg) products;

- extremely heavy (weight of 1 cubic meter varies from 2.5 to 3 tons).

In heavy aerated concrete, crushed stone and gravel mass are used for filling, and in super-heavy ones, substances of a coarse fraction are used. The standardized pallet size holds 1 cubic meter. m. building material. Therefore, you can determine the number of blocks laid out on the pallet by their size. And already this figure will allow you to find out how many pallets you need to order on the construction site.

It is very important that a house built of aerated concrete justifies itself economically. Otherwise, even the relative cheapness of the material itself does not help. By increasing the thickness of the walls in order to inherently provide a decent level of thermal insulation, thereby increasing the overall cost. The subsequent savings in fuel or electricity may not be worth the investment. Standard requirements stipulate that in houses where people live, columns and walls made of autoclaved aerated concrete in the load-bearing walls must be exactly 0.6 m in thickness.

For a self-supporting wall, this figure is 50% less, that is, it is 0.3 m.It is usually believed that when erecting buildings, you need to follow the instructions of SNiP regarding thermal insulation. In fact, these instructions are not strict. There are a number of caveats that allow you to reduce the real performance, starting from the "custom approach". In order to reduce wall thickness compared to regulations, the relative fuel consumption must be taken into account.

Its share per 1 cubic meter. m., must ensure such a temperature difference that dew cannot appear on the inner walls. As practice has shown, reducing the rate of thermal resistance of walls, they increase fuel costs only to a small extent.

Much depends on:

- climate of the area;

- the strength and direction of the winds;

- the quality of thermal insulation;

- reliability of the heat source;

- fuel used;

- Generation efficiency;

- economic feasibility of certain steps.

When calculating the number of blocks stacked on 1 pallet, it must be borne in mind that the dimensions of the pallets themselves may not be equal to 1 m3.

In addition to this size, the following standards also comply with the norms:

- 0,9;

- 1,44;

- 1.8 cubic meters m.

If aerated concrete blocks with a size of 0.6x0.3x0.2 m are laid on these pallets, then it will turn out accordingly:

- 25;

- 40;

- 50 pieces.

Experts note that when buying large quantities of building materials, it is undesirable to round off the calculated values. The "Price" of a miss may be too high. The most difficult calculation is when both non-standard blocks and non-standard pallets are used. In this case, the dimensions of the packs are, achieving a width of 1 m, a height of 120 cm and a length of 80 cm. In total, such a stacking takes 0.96 square meters. m.

When blocks with dimensions of 60x30x20 cm are placed in this way, the real losses will be 60% by volume. When there is a shipment on a large order for the construction of a large house, this is very important. For your information: when the ordered blocks are received, it is required to verify the real figures with those indicated in the accompanying documentation. Some manufacturers put various wastes into aerated concrete that reduce the quality of the finished product. Therefore, it is necessary to carefully measure the dimensions and mass of each brought block.

How to calculate correctly for construction?

The calculation of the masonry of aerated concrete blocks for the construction of a house must begin with determining the volume of one laid out wall. Let its length be 7 m, height 4 m, and thickness 0.6 m. Then the arithmetic volume should be 16.8 cubic meters. m. But this indicator is true only for a completely flat and deaf wall along the entire length.

In reality, you need to subtract:

- openings for windows;

- openings under the doors;

- recesses for arches and other decorative elements.

If a two-story house is being built, the difference turns out to be very significant, as in the construction of large one-story buildings. Even a low price does not justify inattention to this circumstance. For your information, it is required to buy aerated concrete exclusively from trusted suppliers. Some firms try to put defective products in the middle of the pallet. They further increase overall consumption and costs.

Careful calculation also means paying attention to the height of the floors and gables. If there is an attic, the number of blocks is determined, taking into account its properties. Let a house be built with a length of 6 and a width of 9 m, in which the ceiling of the first floor is raised by 300 cm. Above is an attic 2.5 m in height. It is covered with a roof with two slopes.

For simplicity, we will also assume that aerated concrete will be laid out in 1 layer. The structures used are 0.625x0.3x0.25 m. The total area of the external walls will be 90 sq. m. Let the windows and doors, other deducted elements account for 20 square meters. m. Then the size of the outer part of the house under construction will be equal to 70 m2.

To save even more, the dressing in the corners is taken into account. Simply put, they subtract from the previously obtained figure the area of aerated concrete located at the joints. Then 70 is divided by 0.625 and 0.25 - then you get 448 blocks.The number of cubic meters of aerated concrete is simply calculated. It will be 42 m3.

All these calculations apply only to the first floor, and the consumption of building materials for a triangular, for example, attic, is determined separately. First, the area of the room is found out. Then it will need to be doubled and the area of the windows should be subtracted from the result. When calculating, the number of blocks used is always rounded up - this is more reliable.

Next in line are the inner walls of the building. The approach to determining the costs of building materials is the same as in the previous cases. This scheme also applies to the arrangement of partitions inside. For them, aerated concrete is usually taken of a smaller thickness than for capital parts. It is also important not to forget about the 5% correction factor.

It is required to take into account that the wall blocks are for the most part made of a rectangular configuration. But products similar to the letter U are mainly used to form jumpers. Calculating the need for them is somewhat more difficult.

Designs resembling U have the following dimensions:

- in height 25 cm;

- length 50 or 60 cm;

- in width from 20 to 40 cm.

When buying aerated concrete blocks used for external walls, you will have to abandon products thinner than 20 cm.In the internal parts of the premises, structures of 8.5 cm in thickness are actively used. These requirements should also be taken into account when calculating material requirements. Ultra-light aerated concrete is purchased mainly for finishing work and for insulation. Accordingly, its active use makes it possible to reduce the design load on the base of the building.

When using lightweight aerated concrete, the severity of specific blocks is primarily determined by the sand. It is he who turns out to be the densest of the components of the masonry mixture. As for heavy aerated concrete blocks, this is the option that is most often used. After all, high strength and reliability fully justify the increased weight. It is necessary to determine the severity of the structure being created, taking into account not only sand, but also rubble and cement.

Masonry 200 and 250 mm is most often used in monolithic frame construction and in the construction of one-story houses. We are talking only about those buildings that do not require increased heat savings. Professionals for monolithic-frame buildings often choose blocks with a thickness of 25, not 20 cm. In terms of thermal properties, they are identical to a brick layer of 1 m. That is why in many cases just such structures have to be calculated.

And a few more recommendations:

- for high-rise construction, aerated concrete is best suited, the density of which corresponds to the brands D600, D700;

- the same material is recommended for responsible construction (where there is a high seismic hazard, the risk of erosion or other destruction);

- if the blocks of standard dimensions do not suit you, you can take the closest in size and modify it manually.

For information on how to calculate the amount of gazeboten per home, see the next video.

The comment was sent successfully.