What lintels are best for aerated concrete blocks?

The question of what kind of lintels (above the window or above the ceiling) and when are used in the construction of a house is not so simple. Most self-builders, when blocking a wall opening, usually use homemade lintels from a bar, monoliths and reinforced concrete structures using a steel corner. But today, large companies producing aerated concrete products offer solutions that facilitate and speed up work on the construction of door and window openings, and in some cases, allow even to avoid the presence of such structures.

Varieties

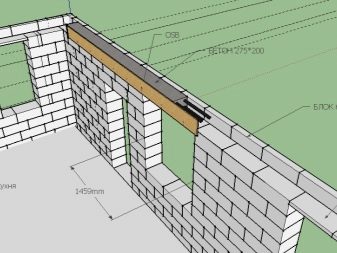

First of all, we will figure out how lintels are chosen for window and door openings. This is decided depending on the availability of materials and the dimensions of the spans that overlap. The largest distance can be bridged with monolithic reinforced concrete beams... Permanent formwork for them is usually made of U-shaped aerated concrete blocks.

Above-floor types of masonry are constantly subjected to significant pressure both during the construction of walls and during the further operation of the building. As a rule, to evenly distribute the loads, the reinforcing bar is installed with the help of wall chasers in such a way as to ensure that the rods enter the grooves. The latter are filled with a solution, and the rod is placed in it in such a way that a part of the rod with a length of 30 cm remains outside.

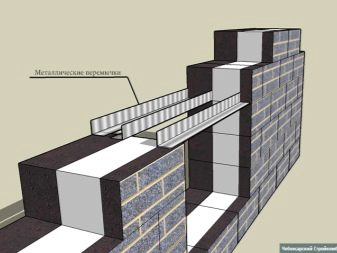

The use of steel corners is not regulated in any way by GOSTs or the rules for the construction of aerated concrete buildings, but it is popular among amateur builders.

In order to preserve as much as possible the properties that prevent heat leakage through the outer walls of the aerated concrete building, you can make a lintel over the window or doorway using one of the aerated concrete products: either reinforced aerated concrete lintels D700, or monolithic reinforced concrete lintels in fixed formwork made of aerated concrete.

If the cellularity of the structure of the structure made of gas blocks coincides with the structures of the material of the building gas block, then this similarity will not cause a decrease in the effective heat capacity. As a result, it will not be necessary to additionally insulate the wall and masonry.

Another acceptable solution that will help bridge the distance of 3 m, may be the arrangement monolithic reinforced concrete structure, cast using non-separable formwork from U-shaped blocks. Their strength can only be inferior to structures such as a monolithic reinforced concrete beam.

No lifting technique is required for the installation of U-block lintels, but efforts are needed for more preparation, and it will also take more time and effort to manufacture such a lintel.

When reinforcing a structure in a U-shaped block using a spatial reinforcing cage (U-blocks with dimensions of 20 cm in width with a tray having a width of 12 cm), it is allowed to use two reinforcing bars (upper and lower). All blocks with dimensions in the width of trays from 15 cm are reinforced with four reinforcing bars (2 upper and 2 lower). In this case, it is necessary to have transverse reinforcing ties with a distance between them of 40-50 cm.

If the wall opening in the aerated concrete wall is not wider than 1.2 m, and the condition for the ratio of the height to the width of the opening is 1 to 2/3, then the opening can be arranged without a lintel at all.With this design, each row is laid using temporary stable formwork, using exclusively aerated concrete block glue.

Structural reinforcement can also be used to reinforce the aerated concrete blocks above the opening. Here it is permissible to use reinforcement d6d8 or thicker, leading its ends beyond the projection of the edges by 50 cm, anchoring the ends at L-shaped corners.

If this proportion is not observed (1 to 2/3) due to lack of height, it is necessary to use an ordinary non-bearing lintel with a shelf down (if the opening is less than 2 m) or a steel corner (if the opening is less than 1.2 m).

Perhaps the use of a corner whose shelf width is less than those described in reference books (11 cm), or a corner of the opening wider than 1.2 m.It should be noted that such an application will be substandard, and if you do it yourself, it will remain at the discretion of the builder.

Features that must be borne in mind if it is planned to build a supporting structure (lintel) of an opening from a steel corner:

- the steel corner must be painted over rust on both sides;

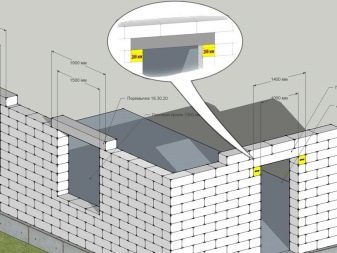

- in this case, the minimum length of support of the corner on aerated concrete should be 20 cm;

- the corners are fastened to each other with a steel tape / welded method / wire ties;

- they must be recessed into the aerated concrete block flush;

- if there are plans for plastering the wall in the future - use a plaster net to wrap it.

Reinforced concrete monolith structures allow covering the widest distances. The proportion of the calculation is as follows: 1 to 20. The calculation with a higher degree of accuracy for the above-window and above-door lintels and gas-block walls must be made in accordance with Ch. 9 STONAAG 3.1–2013.

Reinforced concrete lintels are reinforced in the same way as a reinforced concrete beam: 4–6 reinforcing bars d-12 and thicker with transverse reinforcing clamps every half a meter.

The minimum length of support of reinforced concrete beams on aerated concrete should be at least 35 cm.The support area of reinforced concrete structures of this type must be reinforced by arranging an unloading support, using a mesh of reinforcement in a mortar layer or layers of adhesives for aerated concrete with a thickness of at least 1 , 5 cm.

Overhead reinforced concrete lintels are cast in a stable demountable formwork, the removal time of which is determined by measuring the air temperature at the work site. Structures of this type can be deepened to the thickness of a layer of insulation material, which will necessarily be used to insulate the so-called cold bridges. "ExtPolis" is usually glued to structures of this type with different sections with different adhesives for aerated blocks and fixed using disc dowels.

Additionally, in some cases, it is recommended to install non-separable elements using thermal insulation sheets of the ExtPolis type.

The design features make it possible to choose the options for using the technology during installation, the length of the part of the support of the lintels on the aerated concrete wall, as well as the basic rules for their use.

Support depth

This parameter, as a rule, depends on the type of jumpers.

- Aerated concrete supporting structure with reinforcement: maximum opening - 1 m 75 cm, support depth - 25 cm. No additional insulation is required.

- Load-bearing reinforced concrete structures with non-separable formwork made of U-block structures: the maximum opening is 3 m, the depth of bearing on the masonry is 25 cm. No additional insulation is required.

- Monolithic reinforced concrete bearing structures... Should correspond to the length of the beams - 35 cm. Additional insulation is required. Reinforcement is carried out - 1 m 20 cm. The reinforcement protrudes 50 cm beyond the dimensions of the opening. It is recommended to carry out ordinary reinforcement above the openings.

- Monolithic non-load-bearing reinforced concrete structures 200 cm 35 cm: maximum opening - 1 m 20 cm, depth of support on the masonry - 20 cm. Additional insulation is required.It is a non-bearing structure using a metal corner as a base. It is necessary to deepen in the base of the masonry.

Which ones to choose?

Since reinforced concrete monoliths weigh much more, and such a device is lighter than a gas block, to arrange window and door lintels, it is better to choose gas blocks: they are lighter, easier to install, and they are also more advantageous in terms of their thermal insulation qualities.

Subtleties of installation

Reinforced aerated concrete lintels are durable due to the presence of a steel frame. Also, due to the fact that such lintels are used during the construction of walls from aerated concrete, an optimal surface is obtained, which will subsequently serve the purposes of decoration.

Such bulkheads are a single-span beam that receives a load on its entire surface. The best option when laying aerated concrete is four corners made of steel, properly laid.

It is recommended that the corners overlap the masonry at a distance of about 30 cm. Using jumpers of this type is a rather complicated matter.

The process of installing a metal lintel is as follows:

- the required height is selected;

- reinforcing bars are mounted;

- the formwork is being installed;

- strengthening of the formwork is carried out;

- the reinforcement rods are strengthened;

- concrete pouring of rods from reinforcement is carried out.

When masonry is created over openings, its width and height must be taken into account. This information will be very useful when calculating the structure. If they are installed correctly, this will greatly affect the strength of the entire structure.

For information on how to make lintels in aerated concrete walls, see the video below.

Thank you for the interesting and useful information about jumpers. Now I am building a house and any knowledge about aerated concrete is just the way.

The comment was sent successfully.