How to build aerated concrete walls?

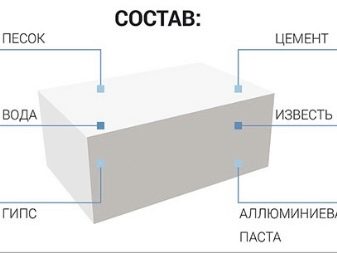

Today, the construction of walls for various buildings is carried out from a large number of materials. One of them is aerated concrete, which compares favorably, first of all, with thermal conductivity. This becomes possible due to the use of aluminum powder in conventional concrete mix. But the strength of such a material will be somewhat lower. Today we will tell you why aerated concrete blocks will be an excellent solution for building a house.

Advantages and disadvantages

To understand whether it is worth building walls from aerated concrete at all, it is necessary to analyze what kind of pros and cons this material has.

So, if we are talking about the advantages of aerated concrete, then it is necessary to highlight:

- good ability to retain heat;

- the material is very easy to process, even with a hand tool;

- the required dimensions and rows of masonry can be easily observed due to the highest geometry accuracy;

- a significantly larger block size than a brick makes it possible to significantly reduce the construction time of an object;

- the material is lightweight, which can significantly reduce the load on the foundation of the building, and therefore extend its service life;

- aerated concrete blocks are completely fireproof material, which favorably distinguishes it among analogues;

- even with the correct implementation of waterproofing and reinforcement procedures, the cost of one square meter of aerated concrete wall will still be lower than that of similar materials.

But like any building material, aerated concrete has certain disadvantages that do not allow us to call it an ideal solution.

We are talking about such aspects:

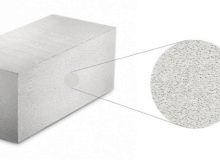

- The porous structure of aerated concrete blocks is the reason for easy water absorption. That is, when using material for the construction of walls, it is necessary to very carefully consider the moment of waterproofing.

- It must be borne in mind that the blocky substance is in a baked state. For this reason, in places where there are increased loads, it can begin to crack. Because of this, even before starting the construction of the object, it is necessary to correctly calculate the minimum size of the wall thickness of the future building. And in places most at risk, the masonry should be strengthened by reinforcement.

In general, as you can see, the material in question still has more advantages than disadvantages. But even the latter, with the correct implementation of waterproofing and strengthening work, can be easily eliminated.

Views

Due to the not too large weight, if we compare blocks with red or silicate bricks by weight, and fire resistance, frost resistance, good sound and heat insulating characteristics, aerated concrete is used for the construction of various elements of buildings of various types, from partitions and load-bearing parts of residential buildings to elements country cottages and garages.

If we talk about the types of aerated concrete, then this material is of several categories:

- D300 - D500. Such blocks are considered light and have a low density coefficient as well as good thermal conductivity. They are usually used as insulation.

- D500 - D900. This category of blocks will be significantly stronger. But their mass will also be significantly larger, and they will conduct heat better. Most often, they are used as the main material for the construction of walls.

- D1000 - D1200. Such gas blocks are considered heavy in weight.Their density will be the highest among all existing categories. They are used for the construction of buildings that require the formation of a solid structure.

Types of aerated concrete blocks can also be divided into three groups according to classes:

- В 2.0 - such aerated concrete is used to form load-bearing type walls for buildings, the height of which is no more than two floors;

- B 2.5 - is used as a material for load-bearing walls, if the height of the building is not higher than three floors;

- B 3.5 - can be used to form load-bearing type walls for buildings with a height of five floors.

Regulatory Requirements

The construction of buildings using various concrete of the cellular group, which includes aerated concrete, is regulated by STO number 501-52-01-2007.

If we talk about the main points on the use of aerated concrete, then it should be noted:

- Limiting the maximum height of buildings. From various categories of aerated concrete, it is possible to create load-bearing walls for buildings, the height of which is up to twenty meters (five floors). If we talk about the height of the walls of the self-supporting category, then it should not be more than nine floors or thirty meters. Foam blocks are used to create load-bearing-type walls, the height of which is no more than three floors or ten meters.

- To create self-supporting walls, you need to use blocks of category B 2.5. If we talk about buildings where there are more than three floors, and B 2.0, if the buildings have a height of three floors.

- The normative document regulates the strength of concrete, depending on the number of floors in the building. If you want to erect external or internal walls of a 5-storey building, then you need to use blocks with a strength of at least B 3.5, and the type of the solution itself should not be worse than M100. If we talk about three-story buildings, then the class of concrete should be at least B 2.5, and the mortar - M75. And for structures with two floors - B2 and M50.

- This normative document also requires the calculation of the most permissible height of the walls made of the specified concrete only after calculations have been made.

It should be noted that this standard only regulates concrete strength issues, but does not give any explanations at all regarding the thermal insulation of the room. Legal entities must first of all comply with the requirements of regulatory documents. Individuals can use them only as a recommendation or guideline when building a garage, a country house or any other building.

During construction, it is necessary to take into account the fact that during operation the moisture content of aerated concrete blocks changes, which increases their thermal conductivity.

Calculation of the thickness of the structure

The thickness of the external aerated concrete walls can, if desired, be calculated by yourself. You should take the standard indicator of the resistance to thermal transfer for a certain area and the thermal conductivity index of the block.

This figure can be calculated by multiplying these indicators by each other. To ensure comfort, the resistance to heat transfer must either be equal to or be greater than the figure of the nominated index, which is calculated by adding the coefficient of the degree-day of the heating period and the coefficient of normal time.

If it is necessary to determine the coefficient of the degree-day of the heating period, then it can be determined by multiplying the degrees for the heating period by the number of days for a certain place.

In addition, when the thickness of the aerated concrete wall of the bearing group is determined, the thermal conductivity index of the material is necessarily calculated, which directly depends on the density. The more it will be, the more will be its thermal conductivity.

If we talk about cottage construction, then M500 aerated concrete is most often used here. Such solutions are heat-insulating and structural. The M600 models, which have high thermal conductivity, also have high strength, which indicates that they will release a lot of heat from the building.

For thermal insulation, the M400 option is excellent. Here, the ratio of pores to total weight will be higher than 75 percent. This indicates that the material will keep warm well. But its strength will be significantly lower. D300 and D400 aerated concrete grades are considered the best for creating aerated concrete exterior walls in terms of thermal insulation properties. Their thickness ranges from 20 to 45 centimeters. Despite these indicators, these materials contain a large number of air pores and little solution, which carries a load.

Aerated concrete of grades D800 and D1000 will be distinguished by the highest strength, but a large wall thickness (from 1 meter or more), necessary in order to retain heat inside the room. As a rule, such brands are used in the construction of trade pavilions and public buildings, as well as structures where there is additional insulation and a large load. But the golden mean, from which you can make internal and interior walls, will be blocks D500-D600, which are usually used in the construction of cottages, residential buildings, as well as other buildings. They have the best balance in terms of strength and thermal conductivity.

How to prepare the glue?

Aerated concrete masonry is made on a glue joint, which is created from a dry mortar with special characteristics, and consists of sand, cement and various kinds of water-retaining, plasticizing and hydrophobic additives. The minimum seam thickness should be 2-5 millimeters, but laying on such a mass is possible with a seam thickness of 8-10 millimeters. Aerated concrete can also be placed on a sand-cement mortar with an average horizontal joint thickness of 12 millimeters and vertical - 10 millimeters.

When laying on special glue, it is necessary to take into account that it reduces the thermal transfer resistance of the wall partitions. For this reason, in dry and hot weather, the material used during laying is best pre-moistened with water.

The creation of an adhesive solution for the construction of aerated concrete wall partitions should be started right before work.

Moreover, the preparation work should be done clearly according to the instructions:

- First, pour a certain amount of water, indicated on the package with the mixture, into a bucket made of plastic.

- Now carefully pour a dry solution there in the required proportion, stirring constantly. It must be left for 10-15 minutes, and mixed again.

- In the process of masonry, it is necessary to stir the mixture several times so that its consistency remains at the desired level.

- To carry out laying in a cold period of time, it is better to use an adhesive solution that contains antifreeze additives.

How to lay?

It is better to put rows of aerated concrete on glue. First, you need to pour the prepared solution into a container, and using a trowel or a scoop, carefully spread it along the entire length of the first row of the wall and level it with a special notched trowel. After that, the aerated concrete blocks should be placed on top of the glue. Their horizontal movement should be no more than 5 millimeters. The seams must be carefully filled with glue in order for the blocks to hold better. Dressing rules should also be followed. Vertically, the seams should be displaced by no more than 0.4 block height, or about 9-11 centimeters. The glue that is squeezed out during this must be removed immediately so as not to allow it to seize. Now all that remains is to check how smooth the masonry was and straighten it using a rubber hammer.

Various types of fixtures can help make the construction of walls easier. We are talking about slats-orders, which make it possible to designate masonry corners. To use them, you need to set them in a vertical position, apply marks that will correspond to the height of the masonry rows.After that, between the orders, it is necessary to pull the mooring rope in order to lay the next row of gas blocks much more conveniently. Now, focusing on the mooring rope, you can simply level the aerated concrete. To do this, you just need to knock a little with a mallet until the glue completely seizes.

As the row is completed, an additional block should be created, which should be the last in the row. You should know what dimensions it should have in order to cut out an element of the required length, and coat it with glue solution on both sides, and then put it in the required place.

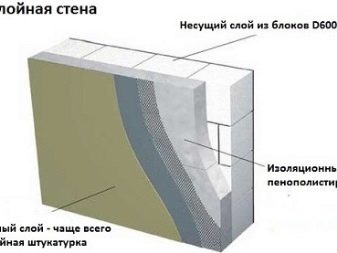

The method of laying wall partitions, as well as the seam size, should be selected depending on the category of walls. For example, single-layer walls can be 30-42 centimeters thick. For their construction, the D300-D500 options are usually used. If the blocks have precise dimensions, then it is better to make thin glue seams. In other cases, a heat-insulating type mortar with a joint thickness of 1-1.5 cm should be used.

The thickness of two-layer blocks can be from 17.5 to 30 centimeters. For them, a lime-cement or heat-insulating mortar is usually used. Aerated concrete groups 600 and 700 can be joined using a glue seam. It is better to insulate a partition made according to this technique with a thin layer of insulating material. The thickness of the insulation in this case should be 9-14 centimeters. But three-layer walls, which are made of this type of concrete, will have the same thickness as two-layer ones. And the construction technique will be identical for them. But the thickness of the insulation can be even less. We are talking about 8-13 centimeters.

It should be said that the more layers a material has, the better the sound insulation and sound insulation of such materials will be. But in general, this is typical for all materials.

Cellular concrete requires great care when laying the first layer, because the strength of the walls, as well as the final appearance of the structure, will depend on the success of this. That is why it is necessary to carefully align the walls, and apply the joint mixture only with the help of a special carriage or a spatula with teeth. If the blocks have profiled grooves on the sides, then during their laying on the vertical seams there is no need to apply mortar or glue. It should be applied exclusively on a smooth surface, and the gaps should be filled with a special elastic material with sound-absorbing characteristics.

For example, polyurethane foam or mineral wool. Only after the solution has dried, which was used to lay the blocks, can you begin to make strobes for communications. After that, you can start applying the putty to the partitions to level them, as well as improve the sound insulation and vapor barrier properties. Although, to improve the vapor barrier properties, not putty should be used, but special types of plaster. Usually we are talking about cement plaster.

From the special mixture, released under production conditions, a solution of higher quality and homogeneous properties is obtained.

Its main components are sand, water and cement. Such a solution is usually made either from a dry special mixture, or simply by mixing the above components. It is easy to make, but the quality will be extremely low. When self-manufacturing a cement-type plaster solution, a special mixture is prepared by the volume of one part of cement of the M400 type or higher and three to five parts of quartz sand.

But a good cement-based plaster can only be created from dry mixes that are produced at the factory.

Such mixtures also contain additives that can:

- regulate the setting time of the solution;

- retain moisture in a fresh layer of plaster, preventing it from passing into the material of the wall partition;

- improve plasticity and ease of laying;

- do not allow efflorescence to appear on the surface;

- enhance the adhesion of plaster and base;

- improve the strength and resistance of the plaster layer to cracks.

It is necessary to apply such a solution to the panels using a special device. Such formulations are easier to apply. Machine plasters are also excellent for manual application. But in the opposite direction, this rule does not work.

Recommendations

Aerated concrete is an effective material for construction due to its highest thermal insulation properties. They are due to its cellular structure.

In order to fully appreciate the advantages of the material in question, you should know some aspects:

- When erecting walls, a special adhesive solution is used, which is laid on the surface of the aerated concrete block in a thin layer several millimeters thick. But the seams should be just like that. If they are larger, the seam will turn into a "cold bridge", and the properties of aerated concrete in terms of thermal insulation will significantly decrease.

- When erecting in cold and temperate climates, it is necessary to insulate aerated concrete walls not only inside, but also outside.

- It is imperative to apply cement plaster to aerated concrete and use materials with the highest vapor barrier properties. This is necessary to protect the material from constant exposure to moisture and to protect it from cracking. If, nevertheless, horizontal cracks appear, then they must be covered with plaster and everything must be done to reduce the effect of steam and moisture.

- Plates of such material should be thoroughly coated with glue solution in order to avoid the appearance of cold bridges and a decrease in the thermal insulation properties of the entire building.

- To obtain a warm home, it is necessary not only to increase the wall thickness to the maximum possible value. The correct type of aerated concrete must also be used. For most climatic zones, it is better to use aerated concrete of type D600 or categories B2.5, B3.5 with a thickness of 300 millimeters. But such a choice is best made based on the heat engineering and strength characteristics.

In general, it is quite easy to build aerated concrete walls, although for this you need to know a number of important criteria. But, nevertheless, such material is quite versatile, because it can be used both in the house and in the apartment. It is also quite simple to work with, so it is a great solution for the construction of walls.

For information on how to make a partition from aerated concrete blocks, see the next video.

The comment was sent successfully.