Bonolit block varieties

One of the relatively new building materials is aerated concrete block, also called a foam block or aerated concrete block. When using it in construction, you can create a very beautiful house, which, due to the properties of the material, will keep the temperature inside the premises well, thereby saving energy. Due to the adhesive composition, which is used to connect the blocks, and their lightness, faster shrinkage of buildings is ensured (or rather, such buildings practically do not shrink).

Bonolit is considered one of the best Russian firms producing foam blocks. This is due to the high quality of products and large production volumes. Bonolit does not deteriorate the composition of aerated concrete for the sake of quantity and uses only environmentally friendly materials. The main types of blocks produced by this manufacturer have a density from D300 to D600.

Bonolit foam concrete is used for the production of load-bearing wall blocks, internal partitions and lintels.

Composition and purpose

Bonolit blocks are manufactured from a set of components. It is a mixture of cement, sand, various blowing agents (for example, aluminum dust) with additives in the form of lime, industrial waste, slag or ash. After mixing the cement with the above-mentioned materials, it is moistened with water, brought to the desired consistency, and poured into a mold to obtain a finished block.

Inside the mold, there is a chemical combination of gas generators with cement or lime. The gases, specifically the hydrogen released during the reaction, give the solution a foamy structure. The diameter of the interconnected pores ranges from one millimeter to three. After the mixture has set, it is taken out and divided into parts of the required size. Then the material is dried.

The general name of the block material sold by Bonolit is AAC (Aerated Autoclaved Concrete - autoclaved aerated concrete, also called aerated concrete or aerated concrete). It was conceived and created in the 1930s in Sweden. Over the entire period of its existence, the technology improved and developed until it took one of the leading positions among the materials used for the construction of buildings.

The manufacture of blocks for walls of various types has some differences. This is certainly taken into account at Bonolit factories as well. Since the external, supporting walls require great strength, the foam blocks are hardened in specialized autoclaves using steam under pressure. This type of block costs, of course, a little more.

For the production of those gas blocks that are used for the installation of internal partitions, curing is used in electrical cabinets for hot drying or simply in ambient conditions.

Advantages

Bonolit gas blocks are widely used in the construction of not only small cottages, houses, utility structures and retail space, but also high-rise buildings.

This is due to the numerous advantages of the material.

- The reliability of gas blocks makes it possible to carry out construction without additional work and materials to strengthen the bearing part and foundation. This allows you to save money, time and resources during the construction process, which means - to reduce the total cost of the building.

- Due to the strength and durability of the material, any buildings built from it do not age and serve for more than 50 years.

- The blocks have high fire safety. This is a big plus for the maintenance of buildings.

- Due to the lightness of the foam blocks, the speed of erection and installation of the building is accelerated up to four times. The installation of the material is carried out on an adhesive composition, which also increases the assembly speed.

- Due to the fact that the structure of the blocks contains foamy pores, they perfectly retain heat and "breathe". This allows you to increase the thermal energy efficiency of buildings at times.

- The foamy structure, which has aerated concrete, made from environmentally friendly materials, is also an excellent sound insulator that does not allow unnecessary sound vibrations into the building.

- The material is resistant to water, which means that the interior will be less susceptible to the influence of excess moisture.

- Geometrically correct block structures make it easy to create straight walls and building corners.

- Bonolit blocks are characterized by ease of processing by any means, be it impact with a drill, saw or other method.

disadvantages

As with any building material, foam blocks also have disadvantages.

- Fastener problem. For such a material, it is useless to use nails, they will simply fall out. All fasteners will have to be done on self-tapping screws.

- Cracks due to improper installation of the foundation. If the foundation is improperly installed, during shrinkage, it can cause cracks both at the places where the blocks are glued to each other, and on the blocks themselves.

- High hygroscopicity. Aerated concrete absorbs moisture due to its foamy structure. He can absorb it up to a third of its volume, while not letting it go out. If the material is saturated with moisture, then its thermal insulation properties will deteriorate. For this reason, aerated concrete blocks require external finishing, for which you can use any materials (from bricks to tiles).

Choosing the right option

One of the most important characteristics of Bonolit gas blocks is density. Its coefficient indicates how dense aerated concrete is in kilograms per m³. A higher coefficient index indicates a greater hardness of the block, a lower coefficient indicates that it retains thermal energy better.

There is also such a parameter as compressive strength. It is denoted by the Latin letter B with a numerical index that indicates the pressure that the block can withstand per square centimeter.

For example, the index B2.5 means that the foam block will withstand pressure up to 25 kg / cm2.

The density of Bonolit blocks is reflected in their name after the Latin letter D.

Accordingly, the foam blocks themselves have a division depending on the coefficient.

- Blocks for curtain walls. Density index - D600. They are used for the installation of external walls and facades, they can withstand increased loads. The load resistance of these blocks is from B3.5 to B5.

- Structural wall blocks. Density index - D500. Purpose - installation of external walls and internal load-bearing floors of houses. The compressive strength of this type of block is from B2.5 to B3.5.

- Wall constructional and heat-insulating blocks. Density index - D400. They are used for the installation of walls of houses with a height of less than three floors, as well as for the installation of internal partitions. The compressive strength of this type of block is from B2.0 to B2.5.

- Heat insulating blocks. They are used both for the installation of internal, not carrying a large load of partitions, and for thermal insulation. Density index - D300. The compressive strength of this type of block is from B1.5 to B2.0.

Aerated concrete block for masonry walls has a standard length of 600 mm, a height of 200 mm, and a width of 200 to 500 mm. The gas block for the installation of partitions has the same length and height as the previous version, but a smaller width - from 75 to 150 mm. The lintel block is 500 mm long, 200 mm high, and 250 to 400 mm wide.

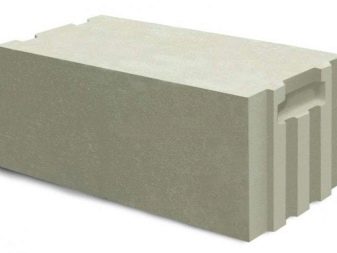

U-shaped foam blocks are used to create a monolithic stiffening belt and internal hidden structures.The tongue-and-groove models have depressions and protrusions on the sides, so that during installation there is no need to lay the adhesive composition on the vertical seams, the gas blocks are inserted into each other.

Blocks of the "hh" type allow, due to their shape, to lay heat-insulating layers between the plates in the partitions.

Another parameter of the gas block is the resistance to the cycles of freezing and defrosting of the material. To indicate how many times the material can be completely frozen and thawed without loss of properties, in the brand of aerated concrete block, the Latin F is used followed by a number that indicates the number of defrosting and freezing cycles. There are options from F15 to F100. All blocks manufactured by Bonolit have an F100 index, that is, they can withstand more than a hundred full freeze / thaw cycles without any problems.

For information on how to lay Bonolit aerated concrete, see the next video.

The comment was sent successfully.