Lifting garage doors: subtleties of the mechanism and manufacture

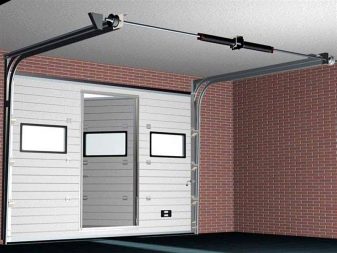

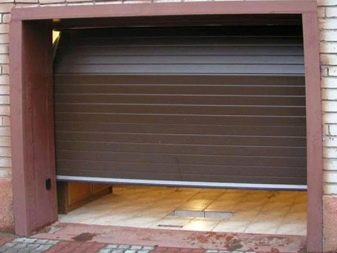

There are many types of garage doors that are reliable and comfortable to operate. The most notable among them are lifting (folding) structures, which, during opening, rise to the ceiling of the room. Such gates have a number of advantages.

Peculiarities

Lifting gates are gaining more and more popularity among car enthusiasts. They do not occupy the area in front of the garage, which is often very important in a metropolis.

Lifting gates have the following advantages:

- the sash rises vertically during opening;

- garage doors are durable, breaking them is not an easy task;

- during the lifting of the sash, the mechanism works silently;

- this type of gate is easy to install, there is no need to cast the foundation for the guides, install roller mechanisms;

- the presence of lateral space is not required, whereas when installing sliding gates, it is necessary;

- the cost of lifting gates is low - this is also an important factor.

Making a lifting gate on your own is a quite feasible task for a person who has the skill of handling a tool. You can also purchase a ready-made set of lifting gates; there are a large number of offers from different manufacturers on the market.

Before starting work on their installation, you should prepare:

- to get acquainted with the features of lifting garage doors;

- make a drawing;

- calculate the amount of material;

- prepare a place in the garage where the structure will be located.

It is recommended to take into account and select the desired option in advance. The lifting gates are sheathed with corrugated sheet, plywood or plastic, PVC insulation or technical wool is laid between the layers, a gate is often made in the sash.

The vertical lifting structure is divided into two types:

- Lifting section... The canvas is assembled from several blocks, they are attached to each other with a rigid frame. Rising up, they bend and collect.

- Swing-over doors... In this case, the web rises up along a curved path.

The advantages of the first option:

- can be used in rooms with any doors;

- installation technology is simple;

- no additional space is required in front of the garage;

- there is an opportunity to use the "dead" space under the roof;

- the sash is a one-piece structure, which has a positive effect on the safety factor;

- the garage will be warm in winter without additional heating, if the door is properly insulated;

- lifting gates can be installed in double and single boxes;

- the design can be supplemented with automation.

There are few design flaws in overhead gates, but they are:

- in case of damage to the leaf of the sash, it will be necessary to change it completely;

- the gate can only be square or rectangular;

- during the installation of the insulation, the weight of the product increases, a significant load falls on the mechanical components, which leads to their wear.

Principle of operation

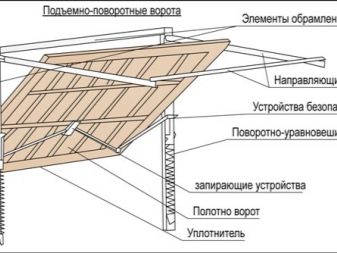

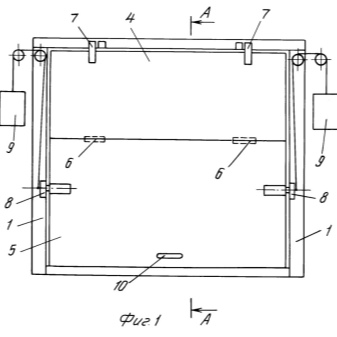

The main elements of overhead gates are:

- frame;

- guides;

- lifting mechanism.

The design can be either automatic and open using the control panel, or manual, when the opening / closing cycles are carried out in manual mode.

There are two types of overhead gates:

- sectional;

- swing-lifting.

In both cases, the gates do not go beyond the premises when they are open. The sectional view is made of longitudinal metal structures, their width does not exceed 50 cm, they are attached using hinges.

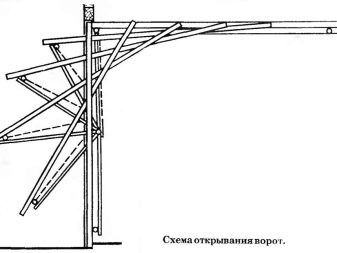

The mechanism is based on the principle where each section moves in two planes:

- first the sash goes up the vertical mount;

- then it moves along a horizontal plane along special guides located under the ceiling.

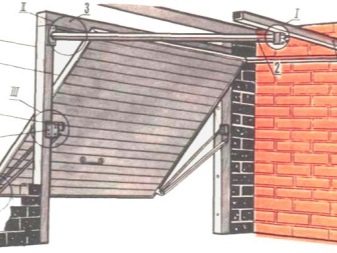

The swing-lift gate is an integral quadrangular structure, in which the sash, turning, is pulled up, moving along special runners.

When the gate is open, the sash is parallel to the ground under the roof.

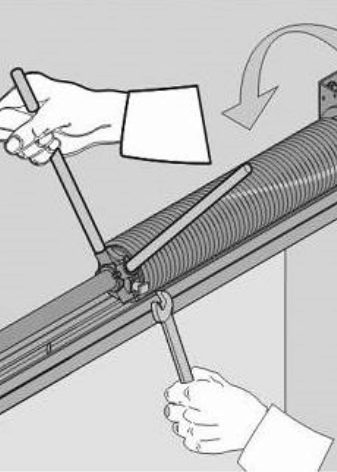

After installation, adjust the springs before starting work. Efforts when opening the gate should be minimal... This factor will be a good guarantee that the mechanism will work for a long time.

After completing the main work, you can install additional devices:

- electric drive;

- anti-burglary mechanism.

When assembling a structure, it is important to ensure that:

- the guides were precisely located along the horizon, otherwise the automation will malfunction;

- the minimum friction should arise only from the functioning of the hinge assemblies;

- adjustment of the spring is done by screwing the nut or by changing the location of the spring itself;

- when using counterweights, it is imperative to fix safety rails that can be adjusted;

- to prevent the gate from falling down unexpectedly, ratchet clutches should be used.

The lifting mechanism can be of several types:

- Spring-lever... The gates in which such a device is present have the greatest recognition among motorists. In operation, such a mechanism is trouble-free, it has excellent indicators of quick lifting. Adjustment requires correct adjustment of the springs and correct positioning of the guides.

- Lifting winch... The doors are often insulated with technical wool. From the outside, a metal profile is mounted, which is additionally sheathed with plastic or plywood.

Often the sash becomes heavy under such circumstances. Additionally, a winch with a counterweight is installed, which is attached to the other edge.

Views

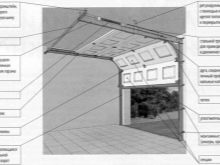

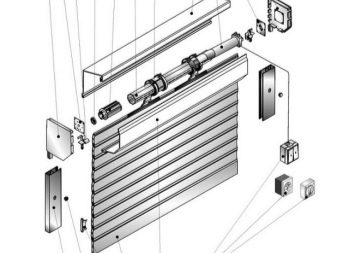

Sectional vertical doors are in great demand. The canvas in them is made up of several blocks, which are interconnected by hinges on hinges. Each panel is no more than 50 cm wide. During the opening, the sections, forming an arc, are displaced.

There are two types of sectional doors:

- for garages;

- industrial use.

The advantage of this design:

- reliability in work;

- simplicity;

- ease of use;

- resistance to mechanical damage.

There is a large selection of sectional doors in different formats on the market. It's easier to buy a ready-made kit, since making such a product with your own hands is a difficult task.

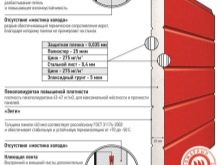

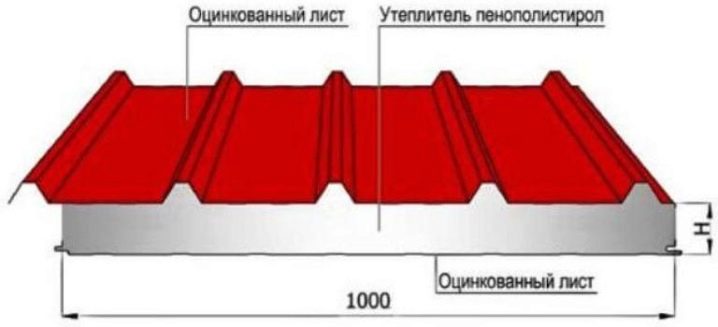

The operation scheme of sectional doors is quite simple: the sections are connected to each other by hinges that move upwards along special tires. Between the two layers, a PVC or mineral wool insulation is laid, the outer surface is sheathed with a profiled sheet. Panel thickness - about 4 cm, which is quite enough for the garage to be warm during the cold season.

Advantages:

- saving space;

- aesthetic appeal;

- reliability;

- economic expediency.

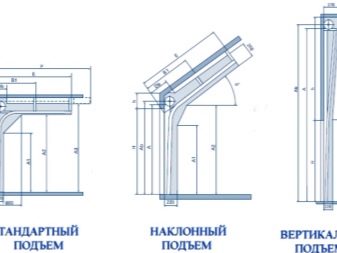

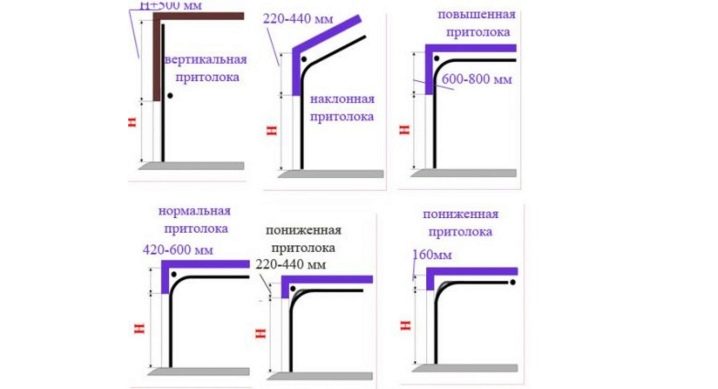

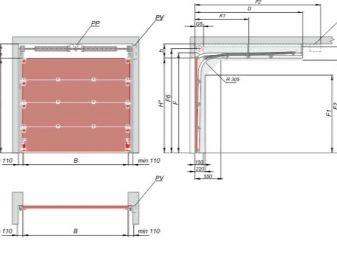

Sectional doors are also differentiated by the type of lift:

- normal - this is the most common type of gate;

- short - this type of gate is mounted with a small lintel size;

- high - makes it possible to save space in the lintel area;

- inclined - horizontal guides have the same inclination angle as the ceiling.

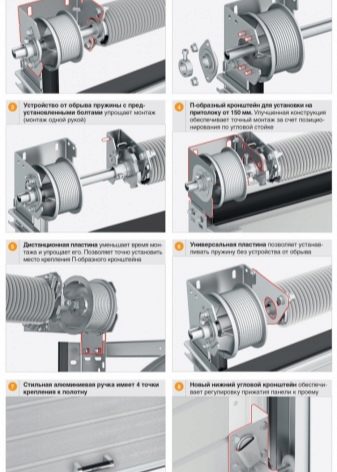

Vertical lift is when the gate moves vertically along the wall.Spring tension - sectional doors in this case are designed for a 10 cm lintel and are the smallest. The lifting mechanism contains a special spring (torsion or simple), which makes it possible to find the optimal mode required for closing and opening.

The mechanism can be controlled from a distance using the remote control. Sandwich panels are interconnected with special locks, which allows the structure to be monolithic.

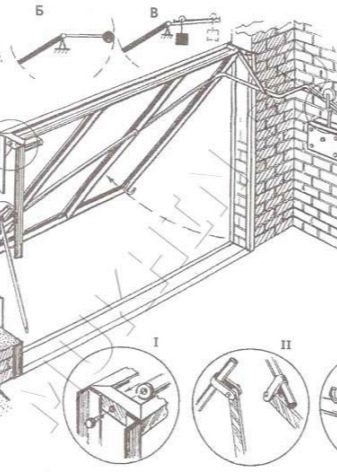

Hinged gates have become very popular. This type of gate allows you to avoid the "invisible zone" when leaving the garage, this factor is often the cause of accidents.

When there are no swing doors, there is much more visibility. Advantages of folding gates:

- are inexpensive;

- easy to operate.

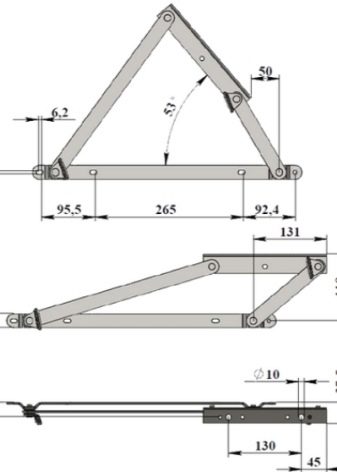

The gate is assembled from two frames that cover the doorway. There is a main support on which the guides are attached. During operation, the main part moves upward on bearings until it is in the area of the horizontal beams. In this case, compensation springs or counterweights are actively involved.

Louvered structures are found in a wide variety of options. The principle of the device is simple: during operation, a flexible roll-up curtain is screwed onto a special shaft, it is located in the area of the lintel.

The end of the flexible blade is fixed to the shaft. During the opening, the roll of the curtain layers is continuously increasing, which fit tightly one on top of the other.

Advantages:

- are inexpensive;

- are lightweight;

- consume the minimum amount of energy.

Among the disadvantages, it can be noted that the turns of the web, being in the roll, rub against each other, the microparticles have an undesirable mechanical effect on the coating layer.

Such a unit has the advantage: when the length in the arms of the consoles is the greatest, the drive voltage can be slightly weakened.

During the opening period, the effective shoulder becomes shorter, the leaf enters the central part of the gate. This factor explains why energy consumption is minimal. The loads on the electric drive itself are noticeably reduced, which contributes to its reliable operation and durability... Another positive quality is that the speed of movement of such gates is high.

Often, instead of a metal frame, a frame is made of beams treated with a special antiseptic primer. The device of a wooden frame will cost less; in terms of stability and reliability, it will differ little from a metal one.

A door often crashes into a vertical gate; it is technically easy to do this. Unfortunately, it is not possible to equip folding gates with a door.

Standard sizes

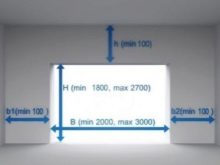

Before you start purchasing materials and preparing a place for a future structure, you should draw a diagram - a drawing. The most important thing is to decide on the basic dimensions of the overhead gates.

Standard sizes vary:

- from 2450 mm to 2800 mm in width;

- from 1900 mm to 2200 mm in height.

Each garage has its own characteristics, the exact dimensions will need to be determined on the spot. It is very important to understand what material the door leaf and frame will be made of.

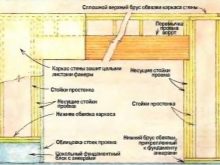

First of all, the manufacture of the gate will require:

- bars 100 x 80 mm and bars 110 x 110 mm for the ceiling;

- reinforcement to secure the frame;

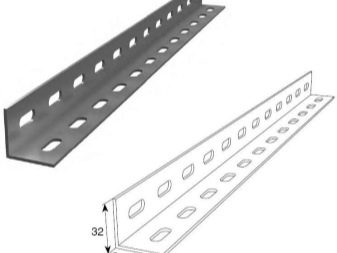

- corners 60 x 60 x 4 mm to strengthen the frame;

- corners for the manufacture of rails 40x40 mm;

- channel 80x40 mm;

- spring with a diameter of 35 mm;

- reinforcement 10 mm;

- canvas to make sashes;

- automatic drive.

The design of the automatic drive is simple, you can do it yourself, you can also find a similar device on the market, knowing what the width and height of the future garage will be, as well as an approximate list of materials that will be required.

It is also easy to calculate the approximate amount of money that will be needed to implement the project.In the course of work, the amount can be adjusted, but if the plan is drawn up correctly, then it will be insignificant (no more than 10%).

Of the tools for installing the gate you will need:

- Bulgarian;

- drill;

- welding machine;

- two-meter level;

- water level;

- adjustable wrenches.

Selection Tips

You can take ready-made drawings, this will significantly reduce the cost of developing your own project. There are various plans, including those from world-renowned manufacturers.

Recently, gates with a wicket door, as well as automatic lifting gates, have been in great demand. Sets and accessories for automatic gates can be bought in the Internet or a regular store... Adjustment of the control unit is not difficult, you can do it yourself.

When buying, you should pay close attention to the following details:

- The guides must have the same cross-section as in the drawing. The gap between bearings and guides is also important, it must also comply with the standards.

- It is important to pay attention to the hinge joints. All components of the structure must move freely at the point of transition from the vertical direction of opening to the horizontal one.

A protective seal is always present at the bending points of the web segment. It serves several useful functions:

- ensures the integrity of the gate;

- prevents fingers or the edges of clothing from getting caught in the gap.

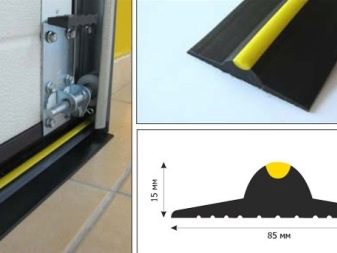

A synthetic seal should be attached to the bottom of the gate so that the door leaf does not freeze.... It is important to calculate the thickness of the panels, it must be optimal.

If there is a need to supply an electric winch, you should correctly calculate:

- necessary effort;

- electric motor power;

- gear ratio of the reducer.

Pay close attention to locks and handles, they must be of high quality... The control panel must also be sealed and withstand mechanical stress.

You can make an entrance lifting gate yourself, while saving a significant amount, but it is recommended to follow all technological requirements. For rolling shutters, the thickness of the strips must be at least two centimeters. The width of such gates is permissible no more than five meters..

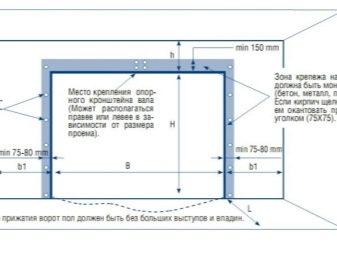

The optimal height of the opening should be made more by 30 centimeters of the upper point of the roof of the car... The lintel and shoulders are located in the same plane. The lintel can be from 30 to 50 cm in size, the shoulders - more than 10 cm.

Aluminum is sometimes used for external cladding. The weight of this metal is three times less than that of iron, the load on the drive will be noticeably less. It makes sense to use steel sheets where there is a large intensive traffic of vehicles... In sandwich panels, it is permissible to use special metal profiles that cannot be cracked. Steel parts should not be less than two millimeters thick and should be zinc coated.

It is better to purchase automation from a well-known manufacturer, since it is difficult to make such a unit with your own hands. A drive, a control panel, a combination lock - it is better to buy all this from one manufacturer, otherwise there is a risk of incompatibility of units. It is recommended to purchase the drive with a higher power., otherwise the risk of breakage increases. Carefully study the bearing markings. They are affixed with the weight that this part can withstand.

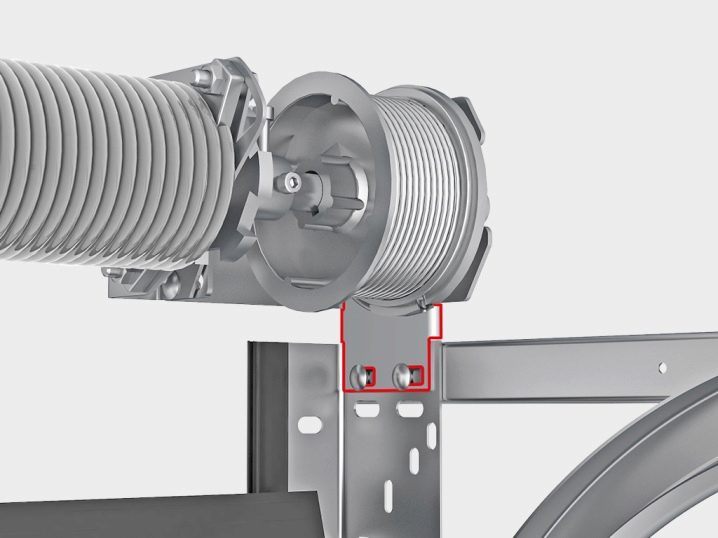

The torsion drum must be made of high-strength aluminum. The lintels and walls, as well as the opening itself, should be reinforced with metal corners. The difference in floor level in the garage is not more than 5 mm... Tires are mounted at the edges of the opening, they go under the ceiling. Sections will move along these nodes.

During work, you should observe safety precautions, use glasses, gloves, construction helmets.

The dimensions of the opening are measured at several points in width and height, according to the first parameter, the maximum value is usually taken, and in height - the minimum. The size of the frame corresponds to the parameters of the opening. If you need to connect the parts with brackets, then the profiles are sawn at an angle of 90 degrees.

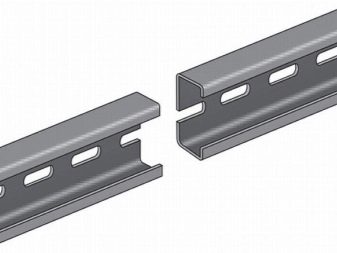

Perforated profiles must be reinforced with planks... Under such circumstances, the jumpers and guides are trimmed so that a small tip remains, it will be needed to fix the parts.

The frame is set using a plumb line. After the structure meets the required level, it is fixed. The vertical guides are fixed using brackets. It is wise to use a mobile fixation so that the part can be adjusted in the desired position. The horizontal guides are inserted into corner inserts and fixed.

To make the package smaller, vertical slats are sometimes divided in two.... The parts are connected to each other using a corner. At the place of installation with a corner rail, there should be no differences between the metal profileotherwise the rollers may jam.

There are two types of balancing nodes:

- torsion shaft;

- tension spring.

They work according to the same principle, only their location is different.

The automatic mechanism with a bulk drive has great power, it can work with heavy gates. In this case, the automation is supplied with a chain mechanism.

It is permissible to use a car alarm for the lifting unit. The drive can be a reverse winch... She works from a 220 volt network and she is able to lift the gate in 125 kg.

Exterior painting of a gate can be quite simple. For example, the monochrome gray color scheme is very suitable for this kind of design.

The gate should be made as small as possible.... Compact sashes are more stable, which significantly reduces the possibility of blocking.

Mounting

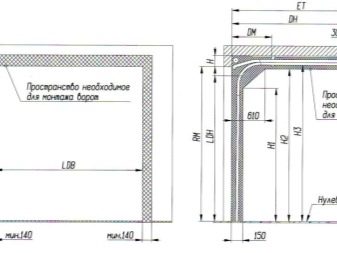

Before installing the gate, it is necessary to carry out a cosmetic repair of the garage - to level the surface of the walls and ceiling so that the guides do not have any deviations.

The frame should go a couple of centimeters into the floor, while it does not really matter whether it will be a home-made gate or factory-made. The concrete filling of the screed can be done when it is anchored vertically.

After assembling the shield, they test it: they put it on ready-made folding guides and check the work.

The end of the work is crowned with the installation of fittings:

- pens;

- locks;

- the heck.

Correct installation of fittings is very important, it largely depends on how long the gate will serve. Often the handles are made from the outside.and from the inside, which increases the functionality of the doors.

All this work can be done by yourself, including correctly adjusting the lifting mechanism. If the gate was purchased in a store, it is recommended to carefully study the information that can be found in the instructions.

If there is a wicket in the door leaf, it is imperative to put a latch... Locks will also be useful if the garage is not located on the territory of the household.

The exterior is primed and painted. Its stages can be divided as follows:

- preparation and assembly of the frame;

- installation of rollers;

- sash installation;

- installation of accessories.

The frame takes on the lion's share of all the loads, so it must be done first. Bars are inexpensive, a frame made of bars can equally replace a metal frame. It will be an economical option, but if everything is done correctly, the principle of operation and the strength of the structure will not be affected.

This is done as follows:

- The plane on which the installation takes place must be perfectly flat. To avoid distortions, prepared bars are placed on it.

- At the connection points, metal corners are used, which are fastened with self-tapping screws.

- The lower part of the timber plunges into the floor by at least two centimeters.

- After the completion of the installation work, testing begins. The box is placed in the door opening, the position of the structure is checked using a level (vertically and horizontally).

If there are no questions, then the frame is fixed with reinforcement, its length can be 25 centimeters... There is one such fastening per one running meter.

Then, in the area of \ u200b \ u200bthe ceiling, guides are placed parallel to the horizon. Once the frame has been installed, the roller mounts can be mounted.

The rail is fixed with bolts with a diameter of 1 cm. It is important to note that during the installation process, a level should always be applied. At the edges of the rail, latches are mounted in the grooves, which allow you to control the movement of the gate.

The canvas can be made from a wide variety of materials. Often the gate is sheathed with durable plastic or stainless steel sheets. Insulation, which is located between the sheets, effectively reduces heat loss.

An automatic overhead gate cannot work without a good motor. Thanks to its work, the doors open and close quickly. Automatic mechanisms must have self-locking mechanisms that will not allow the gate to open if there is no power supply. Such devices are quite durable and reliable.

Successful examples and options

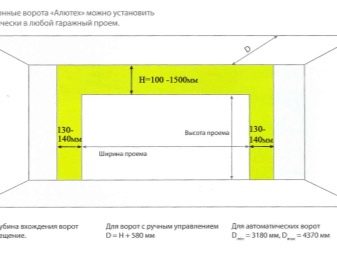

There are several models of gates on the market that are of high quality and are inexpensive. It is recommended to pay close attention to automatic street gates "Alutech Classic"designed for garages up to 3100 mm high and up to 6100 mm wide. The largest overlapping area is 17.9 square meters... Torsion springs are rated for 25,000 cycles.

Sectional quick-lift structures, in which the frame is made of extruded aluminum profiles, are available with double acrylic inserts - this is the best choice for private households.

Alutech products made in the Republic of Belarus have the following advantages:

- pleasant appearance;

- simple principle of operation;

- quality and reliability in work;

- disruption of the spring does not threaten with the fall of the canvas;

- all details fit well;

- the gate can be installed in any opening on the street.

Automatic gates "Alutech Classic" have a panel thickness of 4.5 cm. The gates work silently. They are safe and inexpensive, but, nevertheless, they can be called elite in terms of workmanship.

There is a protection against moisture penetration along the entire perimeter thanks to seals made of a special EPDM elastic material, which retains its properties even at temperatures of -30 degrees Celsius.

There is a built-in wicket (height 1970 mm, width 925 mm), which allows you to enter the room without opening the main sash. There is also a block for manual lifting.

In more detail about the design of the overhead garage door is described in the following video.

The comment was sent successfully.