All about nuts with a press washer

Currently, in hardware stores you can see a huge number of different fasteners that allow you to create reliable and strong connections during the installation process. Nuts with a press washer are considered a popular option. Today we will talk about what it is and what sizes such clamps can be.

Description and purpose

Such fasteners are standard round nuts equipped on one side with a metal nozzle with a raised surface... The sides of such parts have several edges (as a rule, the clamps are in the form of a hexagon), which act as a stop for working with wrenches.

Nuts with press washers differ from each other in strength class, material from which they are made, size and accuracy categories. The nozzle, which these metal elements are equipped with, allows you to regulate the pressure exerted on the surface of the materials. This type is most often used for alloy wheels.

Besides, nuts with a press washer are most often used when connecting assemblies and parts together with construction screws and other fasteners. They are widely used in mechanical engineering and construction. Also, these clips are the most suitable option in cases where it is necessary to evenly distribute a significant load on surfaces with a large area.

The press washer in these cases also acts as an element that does not allow the nut to loosen after installation.

What are they?

These nuts can vary depending on the accuracy class. They are determined according to established standards.

- Class A. Models from this group belong to samples of increased accuracy.

- Class B... Such products are classified as normal accuracy.

- Class C... These nuts with a press washer are included in the coarse accuracy group.

Nuts also differ depending on the material from which they are made. The most common options are models made of steel (stainless, carbon). Such samples are considered the most durable and durable. But there are also options made from copper, brass, and other non-ferrous alloys.

There are varieties of plastic, but they are less durable than metal parts.

At the same time, all models are coated with protective coatings during production. Most often, zinc compounds are used for this. But there can also be products treated with nickel or chrome. Some parts are produced without a protective coating, but these types can quickly become covered with corrosion, which further entails a breakdown of the connection.

These fasteners also differ in the strength class to which they belong. They are indicated by applying small dots to the surface of the products.

All fasteners of this type are classified into three separate groups depending on the finish. When creating clean models, they are completely polished with special tools. All their sides are as smooth and neat as possible.

Medium samples are ground only on one side... It is this part that is attached to the product being fastened. Models with a black finish are not sanded with tools at all when created. In terms of thread pitch, all nuts can be classified as standard, large, small or ultra-fine models.

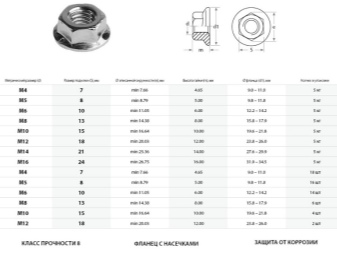

Dimensions (edit)

Press washer nuts are available in different sizes. It is necessary to pay attention to this before purchasing.Indeed, in this case, the choice will depend on which parts will be connected to each other, their sizes.

The main parameter is the diameter of the fastener. The following values are considered the most common: M6, M8, M12, M5, M10... But there are also models with other parameters.

In addition, such nuts can be high or low, in this case the choice will also depend on the requirements for a particular type of connection. Often, elongated varieties are used not only to create a more reliable and durable connection, but also to make it outwardly more accurate.

You can watch a video review of various nuts below.

The comment was sent successfully.