Anti-loosening knurled nuts

During construction work, a large number of different fasteners are used. Nuts are widely used. In stores, customers will be able to find a variety of types of such fasteners. Today we will talk about nuts equipped with a special notch that prevents loosening.

Description and purpose

These fasteners are small hexagonal or square pieces. There is a hole in their central part. Besides, the interior of this hole has a special shape that is designed to transmit torque using a tool.

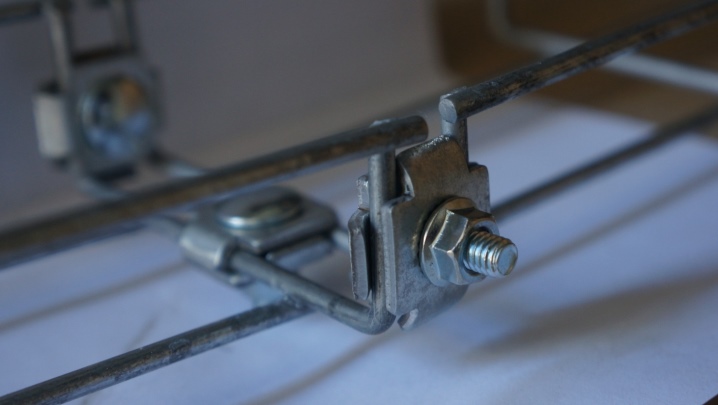

The design of the knurled nuts allows the part to be tightly fixed to the surface.

Such a device is more often called a flange. There are also designs with a completely flat element. These samples are usually sold in sets of 100, 200 or 1000 pieces in one package.

Nuts with a special notch to prevent loosening are considered more reliable fasteners.

Their design will not unscrew during operation for a long time, providing a strong and strong connection of individual parts to each other. These devices are used to connect threaded items (screw, bolt, stud), cable trays.

What are they?

Nuts with a special notch to prevent loosening may vary depending on the material and manufacturing technology.

- Stainless steel elements. This material has a high level of strength, reliability and durability. Notched steel fasteners are also particularly heat-resistant, products can easily withstand sudden temperature changes. Stainless steel models are often used when installing structures that will be located in the open air, since they are quite resistant to environmental influences.

Stainless steel is considered an environmentally friendly material. It is not susceptible to the formation of rust and plaque even after long-term use.

This metal base can be of several varieties. So, austenitic steels are distinguished, they are made with a small addition of chromium and nickel, duplex steels, they are made with the same additives, including nitrogen. Ferritic, martensitic types of stainless steel can also be distinguished separately.

- Galvanized galvanized fixing models. Electroplating is done by applying various chemical and metal coatings to the material. In galvanic galvanizing, a thin layer of zinc is made on the metal in the mass of the electrolyte. In the process of electrolysis, zinc begins to dissolve, after which its ions are deposited on the surface of the product.

Galvanized steel is particularly resistant to the formation of a corrosive layer.

Fasteners made of metal with such a coating, even in conditions of high humidity and sudden temperature changes, can last a long time, provide a strong and reliable connection of parts.

- Low carbon steel. This material is a tough alloy that does not contain alloyed components. This type of steel is made with special impurities and the addition of carbon. The low-carbon mass contains manganese and silicon.

This metal is soft, it is not often used to create fasteners.

It does not have a high level of strength. The metal is characterized by low toughness, it is quite sensitive to mechanical aging, because with repeated loads it will feel the stress concentration. Most often, when making nuts from low carbon steel, special hardening is used to make them as strong and reliable as possible.

Sometimes, in the manufacture of such fasteners, bronze or brass is additionally added to the base alloy. Some types of nuts with a special notch are made from a magnesium base and duralumin.

The nuts can also differ from each other depending on the accuracy class. The following groups are distinguished:

- class A (this group refers to products of increased accuracy);

- class B (nuts of normal accuracy);

- class C (coarse precision models).

Samples that belong to class A are thoroughly processed. There should be no irregularities or other defects on their surface. The second variety is also processed, but slight irregularities may be allowed. Fasteners belonging to the latter variety can be produced with inaccuracies, they do not undergo the same careful processing as the first two types.

Nuts also differ depending on their strength.

There are seven strength classes in total: 4, 5, 6, 8, 9, 10, 12.

These designations show 1/100 of the tensile strength of the screw or bolt to which the nut is connected.

Dimensions and weight

All dimensions are indicated on the fastener packages. The basic designation refers to the thread diameter. The most common models are M6, M8, M10. But also in hardware stores you can see products M16 and M48.

The weight of these fasteners may also be indicated on the packages. They are all relatively lightweight. Models with the smallest thread diameters can weigh as low as 0.32; 0.81; 1.23 grams. Larger fasteners can weigh in the range of 11-64 grams.

Selection Tips

Before purchasing such fasteners, you should pay attention to some of the nuances.

Be sure to look at the size of the nut. In this case, the choice will depend on the size of the parts to be connected.

And also consider the material from which the nut is made. The strongest and most durable are models made of treated steel. The surface of the nuts and notches must be carefully ground, there must be no irregularities on it, otherwise this may affect the reliability of the connection.

High-quality models must have special markings.

It will consist of 4 numbers and Latin letters. Decoding allows you to determine the type of thread (external or internal) and the number of gaps in it. When choosing, it is important to look at the strength and accuracy class.

Quality products must be manufactured in accordance with the state standard (GOST 50592). Foreign fasteners are manufactured in accordance with DIN (6923), ASA and others.

The comment was sent successfully.