All about furniture nuts

The furniture nut is a rather popular fastening element required in the manufacture of cabinet furniture from wood and plywood. In fact, the nut is the main device that ensures the reliability and durability of connecting elements when creating a wide variety of furniture sets. Typically, these parts are made from high quality materials, they have a simple design and a wide range of applications.

Peculiarities

In the old days, nails or self-tapping screws were mainly used for the installation of wooden elements. But, as practice shows, these fasteners are not enough - the connection created by them weakens over time, and this can lead to injuries during the operation of the furniture. That is why furniture nuts have come to the fore in recent years, they are optimal for the formation of high-strength joints.

The furniture nut is a fastening element with a threaded hole. It is made of galvanized steel, as well as of durable non-ferrous metal alloys.

The usual one is used in those areas of fixation where it is required to create the strongest adhesion with the possibility of further dismantling. The part is used to make a threaded and eccentric tie, allows you to create a movable, detachable and one-piece fixation.

Furniture nuts are widely used in the manufacture of kitchen and cabinet furniture, as well as in the assembly of bed frames and sofas. The hardware ensures the strength and durability of the connection, many times reduces the likelihood of thread breaking during operation.

The hardware is used in combination with some other elements, in particular, with bolts. Accordingly, their dimensions and design parameters must completely coincide in thread and diameter, otherwise it will be impossible to ensure a reliable static state when using furniture.

Views

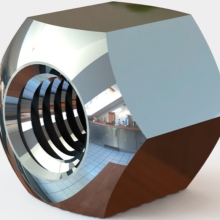

Fasteners with a through hole are widely used in the furniture industry, while furniture nuts can vary in shape, as well as in the parameters of the internal thread. The most common hardware is a hex nut, its technological design allows for rotational movement progressively, evenly, without requiring special physical effort when tensioning.

Nuts can be made in a multi-faceted shape, have a trapezoidal or metric thread. Different diameters make furniture nuts unique - this allows them to be used in any work, even when the weight of the structure is strictly limited.

There are several popular types of nuts on sale that are used in the manufacture of furniture.

- Spherical - the model is a typical hex nut with a cap outer surface and a plug at one end of the threaded hole. It is used in detachable mounts. The cap helps to close bolts and other protruding elements, thereby reducing the risk of injury during product use, as well as giving the structure an aesthetic appearance.

- Wing nut - fasteners with a leveled outer surface, the back thread can have a fine or coarse pitch. A characteristic feature is considered to be a non-standard shape, which somewhat resembles the ears of a Cheburashka, through which screwing is performed. Work with such nuts can be carried out exclusively by hand.Such hardware is indispensable for firmly tightening furniture modules in a limited space.

- Usovaya - such a nut is made with small tendrils on the flange, this design feature allows you to exclude scrolling during the installation of the furniture structure.

The most popular are hammered, mortise and countersunk nuts for furniture.

Hammered

Such nuts are mainly used in automated furniture production; they have not found widespread use in everyday life. In the factory, a hole of a suitable diameter is formed in the structure, after which the nut is hammered in with a hammer.

This ensures accurate assembly and high speed of work.

Mortise

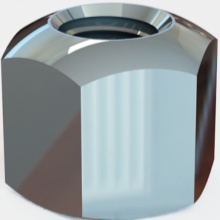

These furniture fittings are manufactured from corrosion-resistant, zinc-plated stainless steel. Outwardly, this design resembles a sleeve, while the internal thread remains flat. A metal disc with a hole at the end is provided. This design allows you to firmly hold the hardware in the material and prevent the risk of twisting during the tightening process. Widely demanded for unilateral fixation.

Hidden

Hidden furniture nuts play a special role among the presented assortment of hardware. Their structure provides the most durable fastening when assembling furniture blocks of any type. A countersunk nut looks like a small bar with a metric type female thread. The hat is semicircular, decorative. All elements are manufactured from corrosion-resistant galvanized steel. Models are indispensable for assembling tables, as well as beds and cabinet furniture, it is distinguished by a decorative look - hardware is almost invisible on the outside of furniture, therefore it is often used in the manufacture of cabinet furniture.

Dimensions (edit)

Furniture nuts are available in a wide variety of sizes. The most popular are M6, M8, M10 - they are most often used in the manufacture of furniture.

Besides, nuts М5 and М12 have found their application in construction works.

Please note that in accordance with the current GOST, the nut designation indicates the diameter of the metric thread.

Selection Tips

Hardware products are presented on the market in a wide variety. Allocate nuts "screwdrivers", "barrels", they can be vane, cylindrical, in the form of a hexagon, a foot, a slot, a pin and a coupling.

Despite this, It is not always easy to choose the right fastener product - these externally simple elements have their own design features, each of them performs its own tasks. All elements connecting individual blocks of furniture structures can vary not only in their shape, size and material characteristics, but also in thread parameters. That is why, when purchasing this or that fastener, it is imperative to take into account the operating conditions of the furniture.

To simplify the choice, manufacturers have introduced a classification of hardware products, indicating the scope of its application:

- nut for universal use;

- high-strength threaded fasteners;

- hardware for high-resource connections;

- fasteners for impact-free riveting.

When choosing one or another element in accordance with the classification, one should take into account its structural features and size, namely:

- internal / external thread diameter - usually written in letters;

- thread pitch - the length between the lateral parts of the profile, measured parallel to the direction of the thread axis;

- the number of thread starts - calculated at the end of the hardware in the place where the step begins;

- screw thread parameters - the size of the axial movement of the nut per revolution.

The diameter of the hole and the parameters of the head also matter.

When choosing hardware, great importance should be attached to the material from which the nuts are made. Their durability and strength depend on this, respectively, the practicality and safety of the connection. High quality products must be resistant to tearing and temperature fluctuations.

In the furniture industry, metric-type threaded nuts are predominantly used, they have a low scrap rate and high wear resistance.

Important. It is also advisable to test the quality of the hardware product in the store. This can be done using a standard open-end wrench, selected in accordance with the size of the nut, it must first be tightened and then unscrewed.

Fixing rules

Installing any furniture nut is not difficult, in fact it is a one-way process. The most important thing in the work is to adhere to the established sequence of actions, this will prevent deformation of the thread, as well as breakage of the bolt.

During installation, a nut tool of a suitable size is usually used, if you perform tightening without it, then there is a high risk of uneven force tension. The main requirements for tightening the nut are as follows:

- the nut to the landing site must be screwed loosely, it is possible by hand, avoiding hesitation, the final installation is performed with a key;

- in the process of twisting the hardware, the end should be located exactly perpendicular to the direction of the axial rod, the presence of potholes and roughness is not allowed;

- in the case of lengthening the bolt, the tightening process should be kept under control; in this case, the turn of the key is performed according to the angle of rotation of the nut.

Before the very beginning of the connection of the structure, it is necessary to complete a complete set of all hardware elements, to make sure that they are compatible in terms of the type of protective coating, type of steel and mechanical characteristics. At the same stage the type of installation, the readiness of the seats, as well as the overall aesthetics of the final connection should be taken into account.

After completing the surface preparation and the hardware itself, it is necessary to clean it of grease, check the functionality of the functional thread. If damaged areas are found, thoroughly clean them and perform a visual inspection in order to determine the accuracy of the fit of the surfaces to be joined.

Tightening the nut directly begins with its landing on the wooden module and initial tightening by about 75%. Next, you need to make sure that there are no gaps around the entire circumference and if the mestizo is located correctly, perform the final tightening of the nut.

When carrying out installation, it is important to adhere to safety standards.

Advice: in fact, it is far from always possible to create a high-quality tightening of a threaded connection, therefore, experts advise taking a shortened service wrench for compact-sized nuts, and a 12-15 cm wrench with a handle for large nuts.

The following video talks about the types of nuts.

The comment was sent successfully.