Features of square nuts

Typically, nut fasteners, including M3 and M4, are round. However, it is equally important to know the features of square nuts of these categories, as well as M5 and M6, M8 and M10, and other sizes. Users need to familiarize themselves with the provisions of GOST and an overview of varieties, take into account the nuances associated with marking.

Description

It is quite appropriate to begin the story about square nuts with a description of their characteristic feature. Like other designs, this type of fastener is screwed onto screws, studs or bolts. However, the unusual shape of the head allows you to hold the fastener without additional tools.

Therefore, a square nut is in demand primarily where the reliability of the connection is most critical. There is no special GOST for such fasteners, but the following standards are applied:

- DIN 557;

- DIN 798;

- DIN 928 (depending on the nuances of the application of the product).

Areas of use

In everyday life, a square nut can be found only occasionally. But in the industry, such a product has become completely commonplace. This type of fastener is widely demanded in the construction of various buildings and structures. Square nuts are used when anchoring needs to be performed (for this purpose, engineers have even developed a special subtype).

They are also used for electrical work in various fields.

From other industries, you can immediately point out the impressive popularity of the square nut:

- in general mechanical engineering;

- in the shipbuilding industry;

- in the manufacture of machine tools;

- in the creation of aircraft of all types;

- in the preparation of tractors, winnowing machines and other agricultural machines;

- in repair and service enterprises for the repair of industrial equipment, vehicles.

Species overview

For installation of structures in housings with thin walls, the use of nuts is recommended according to DIN 557. In this version, there are no sharp corners. One of the ends is equipped with chamfers, while the plane of the other end has no deviations from the even shape. After installation, the nut will be completely motionless. Fasteners are made by screwing in the rod part.

DIN 557 only applies to products with threads from M5 to M16. In this case, accuracy class C is applied. If there are special shapes or unique designs, DIN 962 can be used. Acceptance control is carried out in accordance with DIN ISO 3269. Thread size M25 has been excluded from the standard since 1985.

It is useful to pay attention also to anchor nutaccording to DIN 798. This type of fastener is widely used for fastening roof structures. It is usually used in close conjunction with anchor bolts. However, such fasteners are only relevant for light loads. Due to the small number of turns, this solution is not suitable for critical structures.

The strength class of nuts according to this standard can be:

- 5;

- 8;

- 10.

If there are very high demands on the quality of the connection, the DIN 928 weld-in nuts can be used. They are initially designed for maximum requirements for the quality of fasteners. This method of joining is especially relevant in the engineering industry, where a poor-quality, unreliable connection can result in serious consequences. DIN 928 nuts are fixed by melting special projections on the lugs. Since acid-resistant stainless steels are used for their manufacture, there is no need to fear the onset of corrosion over time.

Of particular note body square nuts. In terms of their structure, they are noticeably more complex than any of the listed types.Contrary to the name, this product is in demand not only in the automotive industry and in auto repair. It is also widely used to secure cables, wires and various other electrical structures. This solution is also suitable for tightly tightening sheets.

The body nut is a square with a thread. A metal "cage" is formed in it. The nut is complemented by a pair of steel legs.

The antennae make it easier to insert into special passages. But this is achieved only by pressing the "antennae" themselves; when they are not secured, installation is carried out in the same way as with a simple nut.

The installation of the body square nut does not require special skills and / or special tools. With enough dexterity, you can get by with ordinary carpenter's pliers and a screwdriver. Another important "tool" is a certain amount of patience. Of course, the reliability will not be the same as that achieved with welding. However, this solution is technologically simpler and does not weaken the metal.

Marking

The most important thing when marking any kind of nuts is given to the designation of their strength. This indicator displays the maximum permissible load that can be generated during operation. Additionally, the marking shows the dimensions of the structure. Strength is calculated taking into account the section, the height of the fastener and the material used for it.

Important: any nut can show the declared strength only when used together with other fasteners of a suitable type.

Nuts of classes 4-6, 8-10, and 12 have the highest level of strength. In such cases, the height of the product will be at least 4/5 of the diameter. The coarse thread is another distinguishing feature. With the same proportions of height and cross-section, but using fine threads, fasteners of medium strength are obtained. It falls into 5, 6, 8, 10, or 12 categories.

The bolt, of course, must have a similar level, because otherwise a stable pairing is impossible. Models of categories 04 and 05 have the smallest strength. Their height can be 0.5-0.8 of the total section. It is not difficult to decipher the strength marking of the nuts. The first figure should be understood as the lowest load level; the second number is increased by 100 times and thus the voltage rating is obtained.

Dimensions (edit)

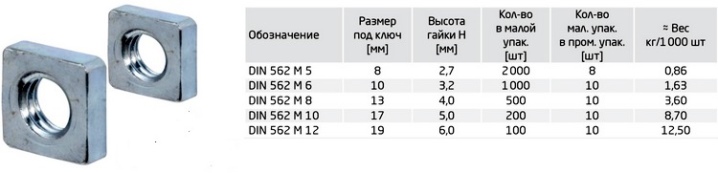

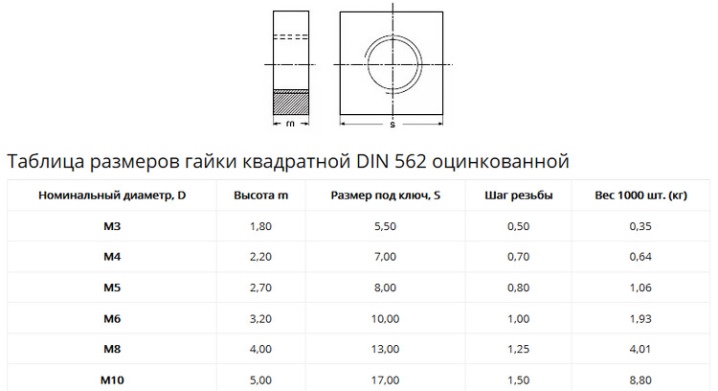

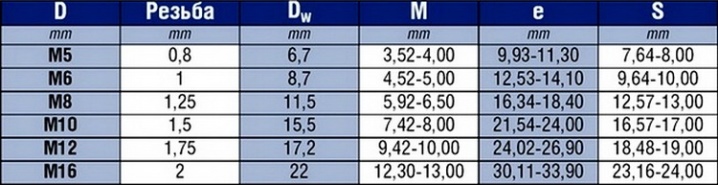

When determining the dimensions of a square nut, it is most correct to be guided by the provisions of the DIN standard. So, for products of category M5, the nominal chamfer is 0.67 cm.The height of the nut reaches 0.4 cm, and its turnkey size is 0.8 cm.

For products of the M6 level, the same indicators will be:

- 0.87 cm;

- 0.5 cm;

- 1 cm.

M3 square nuts have the same dimensions 0.55, 0.18 and 0.5 cm.

For other dimension lines, these dimensions are (the last is a pitch for the main thread):

- M4 - 0.7, 0.22 and 0.7 cm;

- M8 - 1.3, 0.4 and 1.25 cm;

- M10 - 1.6, 0.5 and 1.5 cm.

Strength category "5" is marked by applying 3 dots on the nut itself.

If 6 points are used, then this is already a strength class "8". The 9th and 10th categories are indicated by the corresponding Arabic numerals. Quite often there is a "fractional" marking - for example, "4.6", "5.8", "10.9".

It is also imperative to take into account the difference between metric and inch fasteners.

For more information about the tool for installing square nuts, see the video below.

The comment was sent successfully.