The subtleties of the selection and installation of reinforcement for the foundation

The laying of the foundation has long become traditional in the construction of any building; it ensures its stability, reliability, protects the building from unforeseen soil displacements. The performance of these functions concerns, first of all, the correct installation of the foundation, in compliance with all possible nuances. This also applies to the correct use of reinforcing elements in the structure of a reinforced concrete base, so today we will try to reveal all the subtleties of the selection and installation of reinforcement for the foundation.

Peculiarities

Every builder understands that ordinary concrete without special reinforcing elements is not strong enough in its structure - especially when it comes to heavy loads from large buildings. The foundation slab performs a double role of containing loads: 1) from above - from the building or structure and all the elements inside it; 2) from below - from the soil and soil, which under certain conditions can change their volumes - an example of this is the heaving of the soil due to the low level of soil freezing.

By itself, concrete is capable of taking enormous compressive loads, but when it comes to tension - it clearly needs additional reinforcing or fixing structures. In order to avoid serious damage to the structure and increase its service life, the developers have already developed a type of laying a reinforced concrete foundation for a long time, or laying concrete together with reinforcing elements.

The most obvious plus in laying a foundation with reinforcing elements is its strength. Iron, steel or fiberglass (we will consider the types a little below) provides additional reliability and integrity for the entire installation, the reinforcement fixes the concrete in a given position, evenly distributes the load and pressure on the entire base.

A separate disadvantage of using reinforcement parts is that foundations of this type are installed much longer, their installation is more difficult, more equipment is required, more stages of preparation of the territory and more hands. Not to mention the fact that the selection and installation of reinforcing elements have their own sets of rules and regulations. However, it is difficult to talk about the minuses, since now almost no one uses a foundation without reinforcing parts.

The general parameters that the technician should rely on when choosing fittings are:

- potential weight of the building with all superstructures, frame systems, furniture, appliances, basement or attic floors, even with a load from snow;

- type of foundation - reinforcing elements are installed in almost all types of foundation (it is monolithic, pile, shallow), however, the installation of a reinforced concrete foundation is most often understood as a strip type;

- the specifics of the external environment: average temperature values, the level of soil freezing, heaving of the soil, the level of groundwater;

- the type of soil (the type of reinforcement, like the type of foundation, strongly depends on the composition of the soil, the most common are loam, clay and sandy loam).

As you may have noticed, the choice of reinforcement for the foundation is subject to the same external influences as the foundation itself, and therefore must take into account all the rules and regulations for installation.

Regulatory Requirements

As already mentioned, the installation of reinforcement in a reinforced concrete foundation is regulated by a separate set of rules.Technicians use the rules edited by SNiP 52-01-2003 or SP 63.13330.2012 under clauses 6.2 and 11.2, SP 50-101-2004, some information can be found in GOST 5781-82 * (when it comes to using steel as a reinforcing element). These sets of rules can be difficult for a novice builder to perceive (taking into account weldability, plasticity, corrosion resistance), however, be that as it may, adhering to them is the key to the successful construction of any building. In any case, even when hiring specialized workers to work at your facility, the latter should be guided by these norms.

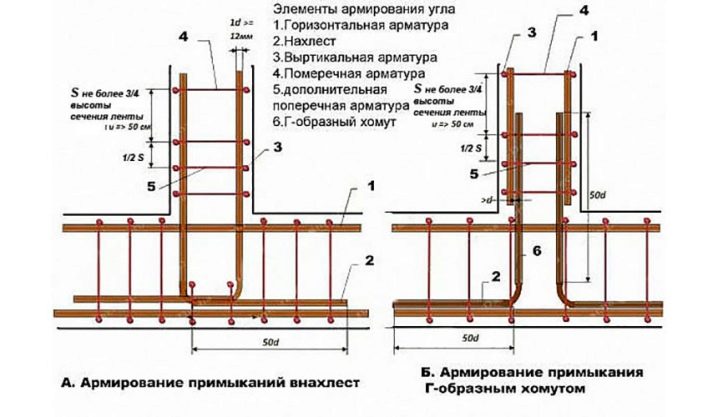

Unfortunately, only the basic requirements for foundation reinforcement can be identified:

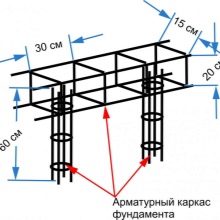

- working rods (which will be discussed below) must be at least 12 millimeters in diameter;

- as for the number of working / longitudinal rods in the frame itself, the recommended figure is from 4 or more;

- relative to the pitch of the transverse reinforcement - from 20 to 60 cm, while the transverse rods should be at least 6-8 millimeters in diameter;

- reinforcement of potentially dangerous and vulnerable places in the reinforcement is carried out by using hats and legs, clamps, hooks (the diameter of the latter elements is calculated based on the diameter of the rods themselves).

Views

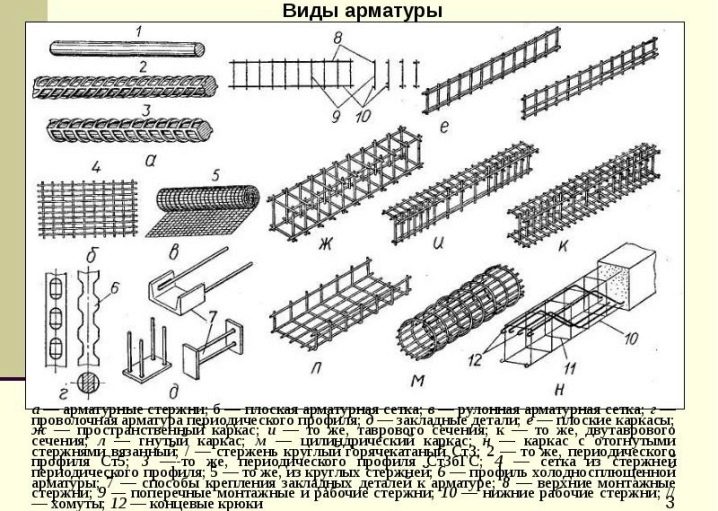

Choosing the right fittings for your building is not easy. The most obvious parameters for the choice of reinforcement for the foundation are the type, class, and also the steel grade (if we are talking specifically about steel structures). There are several varieties of reinforcing elements for the foundation on the market, depending on the composition and purpose, shape of the profile, manufacturing technology, and the characteristics of the load on the foundation.

If we talk about the types of reinforcement for the foundation based on the composition and physical properties, then there are metal (or steel) and fiberglass reinforcement elements. The first type is most common, it is considered more reliable, inexpensive and proven by more than one generation of technicians. However, now more and more often you can find reinforcing elements made of fiberglass, they appeared in mass production not so long ago, and many technicians still do not risk using this material in the installation of large-sized buildings.

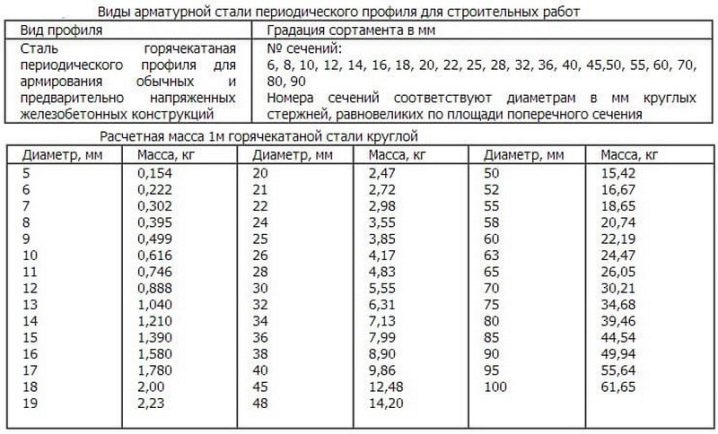

There are only three types of steel reinforcement for the foundation:

- hot rolled (or A);

- cold-deformed (Bp);

- cable car (K).

When installing the foundation, it is the first type that is used, it is strong, resilient, resistant to deformation. The second type, which some developers like to call wire-wound, is cheaper and is used only in individual cases (usually - reinforcement of a strength class of 500 MPa). The third type has too high strength characteristics, its use at the base of the foundation is impractical: both economically and technically costly.

What are the advantages of steel structures:

- high reliability (sometimes low-alloy steel with extremely high stiffness and strength is used as reinforcement);

- resistance to huge loads, the ability to contain colossal pressure;

- electrical conductivity - this function is rarely used, however, with the help of it, an experienced technician will be able to provide a concrete structure with high-quality heat for a long time;

- if welding is used in the connection of the steel frame, then the strength and integrity of the entire structure does not change.

Certain disadvantages of steel as a material for reinforcement:

- high thermal conductivity and, as a result, reinforced concrete foundations let heat through buildings more, which is not very good in living quarters at low external temperatures;

- susceptibility of the material to corrosion (this item is the biggest "scourge" of large buildings, the developer can additionally process steel from rust, but such methods are very economically unprofitable, and the result is not always justified due to differences in loads and the effect of moisture);

- large total and specific weight, which makes it difficult to install rolled steel without specialized equipment.

Let's try to figure out what are the advantages and disadvantages of fiberglass reinforcement. So the benefits:

- fiberglass is much lighter than steel analogs, therefore, it is easier to transport and easier to install (sometimes it does not require special equipment for laying);

- the absolute ultimate strength of fiberglass is not as great as that of steel structures, however, high specific strength values make this material suitable for installation in the foundations of relatively small buildings;

- non-susceptibility to corrosion (rust formation) makes fiberglass to some extent a unique material in the construction of buildings (the strongest steel elements often need additional processing to increase the service life, fiberglass does not require these measures);

- if steel (metal) structures are by their nature excellent electrical conductors and cannot be used in the production of energy enterprises, then fiberglass is an excellent dielectric (that is, it conducts electrical charges poorly);

- fiberglass (or a bunch of fiberglass and a binder) was developed as a cheaper analogue to steel models, even regardless of the cross-section, the price of fiberglass reinforcement is much lower than steel elements;

- low thermal conductivity makes fiberglass an indispensable material in the manufacture of foundations and floors to maintain a stable temperature inside the object;

- the design of some alternative types of fittings allows them to be installed even under water, this is due to the high chemical resistance of the materials.

Of course, there are some drawbacks to using this material:

- fragility is in some way the hallmark of fiberglass, as already mentioned, in comparison with steel, the strength and stiffness indicators are not so great here, this discourages many developers from using this material;

- without additional processing with a protective coating, fiberglass reinforcement is extremely unstable to abrasion, wear (and, since the reinforcement is placed in concrete, it is impossible to avoid these processes under loads and high pressure);

- high thermal stability is considered one of the advantages of fiberglass, however, the binder in this case is extremely unstable and even dangerous (in the event of a fire, fiberglass rods can simply melt, therefore this material cannot be used in a foundation with potentially high temperature values), but this makes fiberglass completely safe for use in the construction of ordinary residential premises, small buildings;

- low values of elasticity (or the ability to bend) make fiberglass an indispensable material in the installation of some individual types of foundations with low pressure, however, again, this parameter is rather a disadvantage for foundations of buildings with high loads;

- poor resistance to some types of alkalis, which can lead to the destruction of the rods;

- If welding can be used to join steel, then fiberglass, due to its chemical properties, cannot be connected in this way (whether it is a problem or not - it is definitely difficult to solve, since even metal frames today are more likely to be knitted than welded.

If we approach the types of reinforcement in more detail, then in section it can be divided into round and square types. If we are talking about a square type, then it is used in construction much less often, it is applicable when installing corner supports and creating complex fence structures. The corners of square-type reinforcement can be either sharp or softened, and the side of the square varies from 5 to 200 millimeters, depending on the loads, the type of foundation and the purpose of the building.

Round type fittings are of smooth and corrugated type. The first type is more versatile and is used in completely different areas of construction production, but the second type is common when installing foundations, and this is understandable - reinforcement with successive corrugation is more adapted to heavy loads and fixes the foundation in its initial position even in case of excessive pressure.

The corrugated type can be divided into four types:

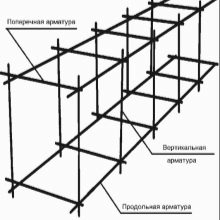

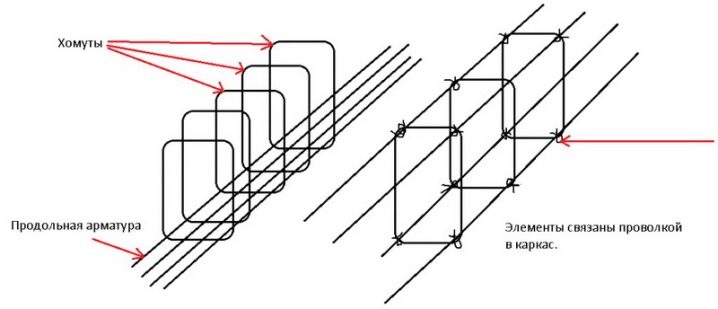

- the working type performs the function of fixing the foundation under external loads, as well as taking care of preventing the formation of chips and cracks in the foundation;

- the distribution type also performs the function of fixing, but it is precisely the working reinforcement elements;

- the mounting type is more specific and is only necessary at the stage of connecting and fastening the metal frame, it is needed to distribute the reinforcing rods in the correct position;

- clamps, in fact, do not perform any function, except for a bundle of reinforcement parts into one whole, for subsequent placement in trenches and pouring with concrete.

There is a classification of corrugated products by the type of profile: ring, crescent, mixed or combined. Each of these types is applicable in specific conditions of load on the foundation.

Dimensions (edit)

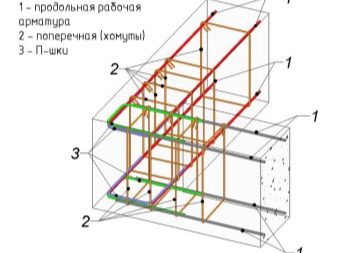

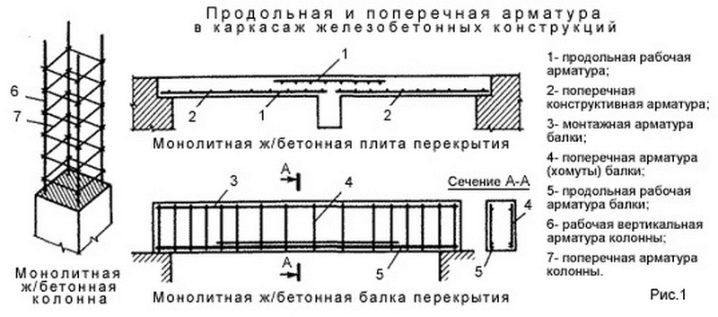

The main parameter for choosing a reinforcement for a foundation is its diameter or section. A value such as the length or height of reinforcement is rarely used in construction, these values are individual for each structure and each technician has his own resources in the construction of a building. Not to mention the fact that some manufacturers ignore generally accepted standards for valve lengths and tend to produce their own models. There are two types of foundation reinforcement: longitudinal and transverse. Depending on the type of foundation and the load, sections can vary greatly.

Longitudinal reinforcement usually involves the use of ribbed reinforcing elements, for transverse reinforcement - smooth (the section in this case is 6-14 mm) of classes A-I - A-III.

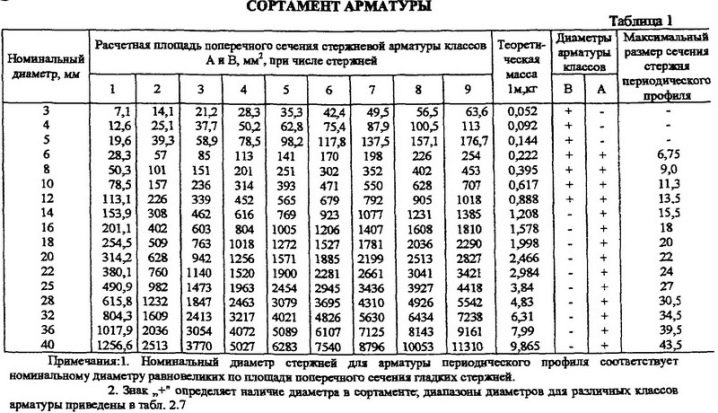

If you are guided by the normative sets of rules, you can determine the minimum values of the diameter of individual elements:

- longitudinal rods up to 3 meters - 10 millimeters;

- longitudinal from 3 meters or more - 12 millimeters;

- transverse rods up to 80 centimeters high - 6 millimeters;

- transverse rods from 80 centimeters and more - 8 millimeters.

As already noted, these are only the minimum permissible values for foundation reinforcement, and these values are rather permissible for the traditional type of reinforcement - for steel-type structures. In addition, do not forget that any issue in the construction of buildings, and especially in the construction of non-standard facilities with a previously unknown potential load, should be resolved individually based on the rules of SNiP and GOST. It is quite difficult to calculate the following value on your own, but this is also a recognized standard - the diameter of the iron frame should not be less than 0.1% of the section of the entire foundation (this is only the smallest percentage).

If we are talking about construction in areas with unstable soil (where it is unsafe to install brick, reinforced concrete or stone structures due to their large total weight), then rods with a cross section of 14 mm or more are used. For smaller buildings, a conventional reinforcement cage is used, however, you should not take the process of laying the foundation connivingly even in this case - remember, even the largest diameter / section will not save the integrity of the foundation with an incorrect reinforcement scheme.

Of course, there are certain schemes for calculating the diameter of rods, however, this is a "utopian" version of the calculation, since there is no single scheme that combines all the nuances of the construction of individual buildings. Each building has its own unique characteristics.

Scheme

Once again, it is worth making a reservation - there is no universal scheme for installing foundation reinforcement elements. The most accurate data and calculations that you can find are just individual sketches for individual and most often typical buildings. By relying on these schemes, you risk the reliability of the entire foundation. Even the norms and rules of SNiP may not always be applicable to the construction of a building. Therefore, it is possible to single out only individual, general recommendations and subtleties for reinforcement.

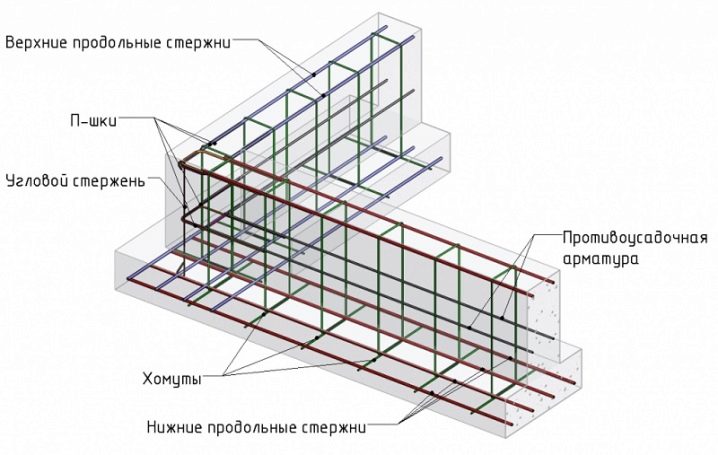

Returning to the longitudinal bars in the reinforcement (most often they are class AIII reinforcement). They should be placed at the top and bottom of the foundation (regardless of its type). This arrangement is understandable - the foundation will perceive most of the loads from above and below - from soil rocks and from the building itself. The developer has the full right to install additional tiers to further strengthen the entire structure, but keep in mind that this method is applicable for bulk foundations of large thickness and should not violate the integrity of other reinforcement elements and the solidity of the concrete itself. Without taking into account these recommendations, cracks and chips will gradually appear at the points of attachment / connection of the foundation.

Since the foundation for medium and large buildings usually exceeds 15 centimeters thick, it is necessary to install vertical / transverse reinforcement (here smooth AI class rods are often used, their permissible diameter was mentioned earlier). The main purpose of the transverse reinforcement elements is to prevent the formation of damage to the foundation and fix the working / longitudinal rods in the desired position. Very often, transverse type reinforcement is used to produce frames / molds into which longitudinal elements are placed.

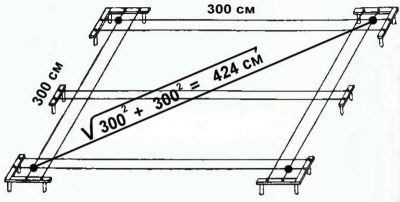

If we talk about the laying of the strip foundation (and we have already noticed that reinforcing elements are most often applicable for this type), then the distance between the longitudinal and transverse reinforcement elements can be calculated based on SNiP 52-01-2003.

If you follow these recommendations, then the minimum distance between the rods is determined by such parameters as:

- section of reinforcement or its diameter;

- concrete aggregate size;

- type of reinforced concrete element;

- placement of reinforced parts to the direction of concreting;

- method of pouring concrete and its compression.

And, of course, the distance between the reinforcing bars themselves already in the bundle of the metal frame (if we are talking about the steel skeleton) should be no less than the reinforcement diameter itself - 25 or more millimeters. There are schematic requirements for the distance between longitudinal and transverse types of reinforcement.

Longitudinal type: the distance is determined taking into account the variety of the reinforced concrete element itself (that is, which object is based on longitudinal reinforcement - column, wall, beam), typical values of the element. The distance should be no more than twice the height of the object's section and be up to 400 mm (if the objects of the linear ground type - no more than 500). The limitation of the values is understandable: the greater the distance between the transverse elements, the more loads are placed on the individual elements and the concrete between them.

The step of the transverse reinforcement should not be less than half the height of the concrete element, but also not be more than 30 cm.This is also understandable: the value is less when installed on problem soils or with a high level of freezing, will not have a significant effect on the strength of the foundation, the value is more possible, however, it is applicable to large buildings and structures.

Among other things, for the installation of the strip foundation, do not forget that the reinforcing bars should rise 5–8 cm above the level of concrete pouring - for fastening and connecting the foundation itself.

How to calculate?

Some recommendations for the design of reinforcement have already been presented above.At this point, we will try to delve into the intricacies of the selection of fittings and will rely on more or less accurate data for installation. Below will be described a method for self-calculation of reinforcing elements for a strip-type foundation.

Self-calculation of reinforcement, subject to some recommendations, is quite simple to perform. As already mentioned, corrugated rods are selected for horizontal foundation elements, smooth rods for vertical ones. The very first question, in addition to measuring the required diameter of the reinforcement, is the calculation of the number of rods for your territory. This is an important point - it is necessary when purchasing or ordering materials and will allow you to draw up an accurate layout of reinforcing elements on paper - down to centimeters and millimeters. Remember one more simple thing - the larger the building's dimensions or the load exerted on the foundation, the more reinforcing elements and thicker metal rods.

The consumption of the number of reinforcing elements per individual cubic meter of a reinforced concrete structure is calculated based on the same parameters that are used to select the type of foundation. It is worth noting that very few people are guided by GOST in the construction of buildings, for this there are specially developed and narrowly focused documents - GESN (State Elementary Estimated Norms) and FER (Federal Unit Prices). According to the hydroelectric power station for 5 cubic meters of the foundation structure, at least one ton of metal frame should be used, while the latter should be evenly distributed over the foundation. FER is a collection of more accurate data, where the quantity is calculated not only based on the area of the structure, but also from the presence of grooves, holes and other additional. elements in the structure.

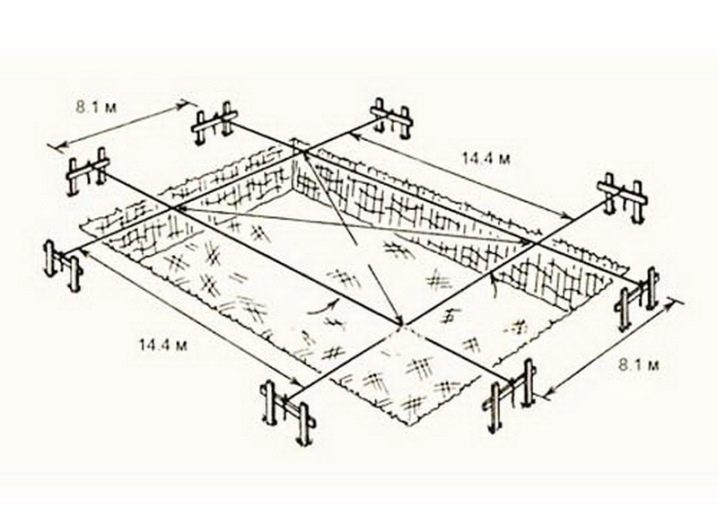

The required number of reinforcing bars for frames is calculated based on the following steps:

- measure the perimeter of your building / object (in meters), for the functioning of which it is planned to lay the foundation;

- add the parameters of the walls to the obtained data, under which the base will be located;

- the calculated parameters are multiplied by the number of longitudinal elements in the building;

- the resulting number (total base value) is multiplied by 0.5, the result will be the required amount of reinforcement for your site.

We advise you to add about 15% more to the resulting number; in the process of laying the strip foundation, this amount will be enough (taking into account the cuts and overlaps of the reinforcing bars).

As already mentioned, the diameter of the steel frame should not be less than 0.1% of the section of the entire reinforced concrete base. The cross-sectional area of the base is calculated by multiplying its width by its height. The base width of 50 centimeters and the height of 150 centimeters form a cross-sectional area of 7,500 square centimeters, which is equal to 7.5 cm of the cross-section of the reinforcement.

Mounting

If you follow the previously described recommendations, you can safely proceed to the next stage of the installation of reinforcing elements - installation or fastening, as well as related actions. For a beginner technician, creating a wireframe can seem like a useless and energy-intensive task. The main purpose of the frame being constructed is the distribution of loads on individual reinforcing parts and fixing the reinforcing elements in the primary position (if the load on one bar can lead to its displacement, then the load on the frame, which includes 4 corrugated bars, will be much less).

Recently, you can find the fastening of reinforcing metal rods through electric welding. This is a quick and natural process that does not violate the integrity of the framework. Welding is applicable at great depths of the foundation. But this type of attachment also has its drawback - not all reinforcing elements are suitable for boiling them. If the rods are suitable, they will be marked with the letter "C".This is also a problem for the frame made of fiberglass and other reinforcing materials (less known, such as some types of polymers). In addition, if a power-type frame is used in the foundation, then the latter at the attachment points should have a relative freedom of displacement. Welding limits these necessary processes.

Another way of attaching rods (both metal and composite) is wire knotting or strapping. It is used by technicians when the concrete slab is no more than 60 centimeters high. Only some types of technical wire are involved in it. The wire is more ductile, it provides freedom of natural displacement, which is not the case with welding. But the wire is more susceptible to corrosive processes and do not forget that buying a high-quality wire is an additional cost.

The last and least common method of fastening is the use of plastic clamps, however, they are applicable only in individual projects of not particularly large buildings. If you are going to knit the frame with your hands, then in this case it is recommended to use a special (knitting or screw) hook or ordinary pliers (in rare cases, a knitting gun is used). The rods should be tied at the place of their crossing, the wire diameter in this case should be at least 0.8 mm. In this case, knitting takes place at once with two layers of wire. The total wire thickness already at the crossing may vary depending on the type of foundation and loads. The ends of the wire must be tied together at the final stage of fastening.

Depending on the type of foundation, the characteristics of the reinforcement may also change. If we talk about the foundation on bored piles, then ribbed type reinforcement with a diameter of about 10 mm is used here. The number of rods in this case depends on the diameter of the pile itself (if the cross section is up to 20 centimeters, it is enough to use a metal frame with 4 rods). If we are talking about a monolithic slab foundation (one of the most resource-intensive types), then here the diameter of the reinforcement is from 10 to 16 mm, and the upper reinforcing belts should be placed so that the so-called 20/20 cm grids are formed.

It is worth saying a few words about the protective layer of concrete - this is the distance that protects the reinforcing bars from the external environment and provides the entire structure with additional strength. The protective layer is a kind of cover that protects the overall structure from damage.

If you follow the recommendations of SNiP, then a protective layer is necessary for:

- creating favorable conditions for the joint functioning of concrete and reinforcing skeleton;

- correct strengthening and fixing of the frame;

- additional protection of steel from negative environmental influences (temperature, deformation, corrosive effects).

According to the requirements, metal rods must be completely embedded in concrete without protruding individual ends and parts, so that the installation of a protective layer, to some extent, is regulated by SNiP.

Advice

Do not be alarmed at the sight of our recommendations. Do not forget that the correct installation of the foundation without assistance is the result of many years of practice. It is better to make a mistake once, even following the specified norms, and know how to do something the next time, than to constantly make mistakes, relying only on the advice of your acquaintances and friends.

Do not forget about the help of SNiP and GOST regulatory documents, their initial study may seem difficult and incomprehensible to you, however, when you get at least a little familiar with installing reinforcement for the foundation, you will find these manuals useful and you can use them at home over a cup of tea or coffee. If any of the points turns out to be too difficult for you, do not hesitate to contact specialized support services, specialists will help you with accurate calculations and drawing up all the necessary schemes.

For information on how to quickly knit reinforcement for the foundation, see the next video.

The comment was sent successfully.