Column foundation: calculation and making by hand

The beginning of construction is the erection of a supporting structure under the house. Often, the foundation on the pillars acts as it. Any responsible developer must know exactly how such work is done - at least for the sake of full control over the work of the hired teams.

What it is?

Intuitively, it is clear that the columnar foundation is a set of supports standing separately from each other under the structure. It will be easier to understand what this type of foundation structures is if you compare its characteristics with the pile type of support for a house, which is closest in appearance. In both cases, instead of a monolithic base, there are isolated anchor points.

But there is still a difference:

- the pile can go into the soil up to 5 m, while the pillar is not buried so much;

- the pillars are supported only on the sole, and the piles are still held by the side faces;

- almost always, for a structure with comparable parameters, the cross-section of the piles is inferior to the diameter of the pillars;

- there is also a certain difference in the sphere of their use.

Common features are the geometry of the section (circle or square), the allocation of isolated supports and (optionally) the grillage. The main areas of application of the columnar props are:

- one-story buildings of an industrial and public nature (the most massive pillars are required);

- frame houses;

- houses in which a frame and a shield are combined;

- lumber and log structures;

- various enclosing elements.

Features and characteristics

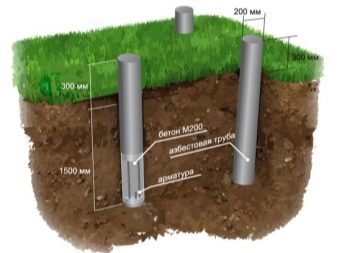

In order for the foundation on the pillars to really fulfill the task, you need to take care of a number of important points, including the formwork. According to official regulations, instead of panel formwork, a selection of pipes made of durable plastic or asbestos cement can be used... This solution is often more convenient. Despite the external resemblance to bored piles, it is categorically impossible to use roofing material for formwork.

Since the outlet below the freezing line is not guaranteed, it is required to fill the pillars with non-metallic substances. Roofing material rolls cannot provide the required rigidity and protection against water penetration. In any case, you should organize unhindered access to the place where the post expands. The trenches to be prepared must be covered with sand and crushed stone, and the foundation must also be poured.

In order to expand the surface used for support, the pillar block expands due to slabs that must have formwork.

When polyethylene pipes are used as formwork for the base of a building, it is allowed to use bored technology without soil development. Wells are being prepared, the sole is expanded using a special tool. But still, the classic structure of the columnar foundation implies the phased preparation of the slab sole.

Hydraulic insulation is done in 2 or 3 layers, complemented by sealing joints with mastic. Traditional panel formwork is considered the most practical and reliable solution. In any case, the formwork must be fixed so that it does not move sideways. The well is made 200 mm wider than the outer diameter of the pipes.

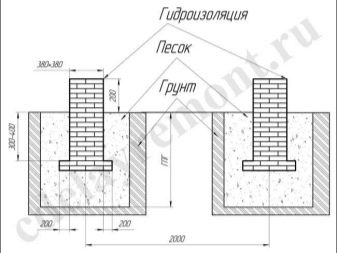

To compensate for the instability of the geometry of the pillars, at the last stage of the zero cycle, a rigid strapping is performed.The grillage can be made above ground, hanging or with burial. Beams should be 70-150 mm distant from the ground, the exact figure is determined by the concentration of clay in the soil.

Thinking over the device of a columnar foundation, it is very important not to forget about the recommendations contained in GOST and SNiP. The state standard allows the construction of such foundations with and without a grillage. The deepened variety is considered more stable and stable, since the lower parts of the supports go deeper than the ground usually freezes. Therefore, the columns will not experience pressure during frost heaving.

Shallow deepening is permissible during construction work in the middle zone of the Russian Federation.

According to official regulations, when building shallow foundations on heaving soil with a clay layer, it is recommended to remove soil 0.2 m deeper than the freezing zone.

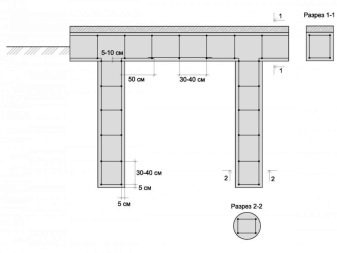

From the bottom of the excavation, the space is covered with sand of a coarse fraction, bringing the mass to the lowest point of the pillar. The sand mass must be tamped thoroughly after moistening. The technology provides that a foundation with a shallow deepening is built taking into account the mass of the structure and the cross-section of the pillars. These indicators affect the distance between the posts. But anyway, less than 150 and more than 300 cm should not be.

If the formwork is made from plastic pipes or from rolls of roofing material, you can significantly save money. It will only be necessary to do the filling in stages, while backfilling the formed pipe in parallel. This technique avoids the expansion of the diameter during operation. Reinforcement of round formwork should be no less careful than when using square structures or panels.

The perimeter of the reinforcing belt of the structure cannot go beyond its contour, moreover, the metal is immersed in concrete by 15-20 mm.

Preparation of pillar foundations with grillages is made necessarily with the withdrawal of longitudinal reinforcing rods beyond the upper parts of the columns by 0.25 - 0.35 m. Columns are ready no earlier than 5 days (in dry and hot weather). If there is precipitation or it is relatively cold outside, it is recommended to wait 20-25 days before removing the formwork. It is recommended to use only steel rods for hardening. In longitudinal section, they must correspond to class AIII and have a diameter of 1.2 - 1.6 cm.If the cross section is to be strengthened, it is advisable to take a bar with a smooth outer side with a cross section of 0.6 to 0.8 cm.

When creating a reinforcing belt, it is advised to use only special steel wire. Even the most professional welding work degrades the characteristics of the metal and lowers the strength bar.

When installing round pillars, reinforcement should be installed from 3 longitudinal rods, the edges of which are placed across at a distance of 0.15 to 0.2 cm. The square supports are already reinforced with four rods. According to GOST standards, the area of the base plate must be larger than the area of the column base.

It is categorically not allowed to deepen the grillages into the soil or perform them at the same level with the surface.

As soon as the seasonal ground movement begins, the whole structure, no matter how strong the concrete is used, no matter what the grade of reinforcing steel, will be deformed. For houses on sand, the distance between the soil and the strapping belt should be at least 50 mm, and on rocks prone to active movements - at least 150 mm. Particular attention should be paid to such details as picking up. It is found only in columnar foundations, and therefore the experience of building other structures will not help in the least to make the right decision.

The reason is simple: the gap separating the supports from the floor of the first tier on one side, from the ground on the other, has no insulation, as if hanging in a void. This creates one of the most unpleasant situations for any designer. If a pick-up is made, heat losses are immediately reduced and the prevention of seepage of precipitation and soil water is ensured... The specific parameters of the pickup can be very different, but in any case, its minimum the height is 50 cm above the ground... Competent execution of the work allows you to create not just another heat-insulating block, but also an aesthetically elegant design.

Enough pick-ups from DSP are widespread, which are formed from blocks of a pre-planned size, the installation of the main parts is carried out on pre-arranged guides. The advantage of this approach is the increased speed of work. But to a large extent it is overshadowed by a decrease in thermal qualities, which necessitates the use of insulation materials.

If the filling is made of concrete with stone, they dig a trench in which sand is poured. Next, a concrete pad is poured, which serves as a support for the stone element.

Such manipulations require great skill and scrupulous execution of construction rules. Therefore, you will have to turn to professional bricklayers if you do not have your own skills of the required level. If you plan to use only concrete, it will also be impossible to do without adding sand. Pick-up is made 0.3 m thick... Such a design is created with your own hands quite quickly, but you need to be careful and attentive when working.

Insulation of pillars with a height of 0.7 m is carried out especially scrupulously. Initially, a frame is prepared based on a metal profile. The sheet insulation material is attached to the inner side of the frames, a profiled flooring is placed outside, which covers the thermal protection from destructive influences. To saturate the gap from the surface of the ground to the bottom edge of the house, loose insulating material is used.

A profile sheet is used around the perimeter more often than other options due to its external grace, quick installation and reliability of the structure.

Views

Even a brief acquaintance with the device of the pillar foundation shows that it can be very diverse in design. But in addition to creative delights and the prescriptions of official standards, there is a common building practice. It should also be taken into account when performing work, including when using plastic pipes.

The advantages of this design are:

- long period of use;

- excellent resistance to cold;

- combination of lightness with strength and mechanical rigidity;

- a wide range of dimensions;

- sliding of intumescent soil over the surface (this should be the case in theory).

As for the use of gray pipes intended for laying internal sewage systems, they allow you to save a little, but few will satisfy the service life in the ground. Any polymer pipes are more expensive than solutions based on roofing material.

When it is planned to put a post expanding from below, a garbage bag is placed in the right place, attached with tape... It will become the concrete receptacle that forms the heel of the pillar. The broadening is reinforced in the shape of the letter L.

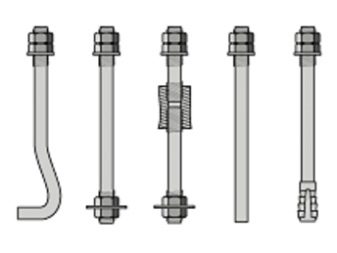

When forming a bar-shaped lower strapping, anchor pins, poured into the post itself, will help to connect it to the pillar foundation.

The PVC formwork is made permanent and after that the expansion is only being prepared. Each post must be laid at the same level as the others. The horizontal is determined using a laser or hydraulic level, the rope is pulled along the marked line.

Fundamentally different from the described column-support type of foundation. It is worth noting that it is only considered suitable for temporary or very light structures. But you can get a similar design in just 2-3 days even when working with your own hands. And start to put walls can be done in 10-14 days In most cases. If the work is organized correctly and the basic technical requirements are taken into account, costs can be reduced by 50% compared to the pile-screw version or shallow tape. Another undoubted advantage is the saving of heat, the difference is especially noticeable in buildings, where people are only occasionally.

It should be remembered that the decisive answer as to whether the foundation design will be reliable can only be obtained from experience in a specific area. In this case, if there is also a building with a pile-screw base there, you need to check the condition of its supports for 3 or 4 years after the start of operation. Even the most advanced and technically strengthened pillar foundations will not be able to support heavy brick houses with asymmetric loads.... In addition, the mechanical strength of the soil layers closest to the surface is insufficient; they invariably become saturated with moisture even in relatively dry places.

In any case, the choice of pillars means refusing to create a basement, semi-basement or other options for mastering the basement. No matter how hard you try to arrange the pillars themselves, digging a hole that meets the technical requirements and laying out a stable box will turn out to be impossible.

To perform a support-column foundation, one of four schemes is used:

- creation of pillars based on rubble stone or brick;

- the use of factory concrete blocks of standardized size;

- casting of truncated pyramids with all details tied to the ground due to additional technical solutions;

- pouring concrete into the formwork connected to the bed of gravel.

The shallow deepening of the pillars makes it possible to achieve excellent protection from water, organize full-fledged drainage and, to some extent, simplify the work on insulation.

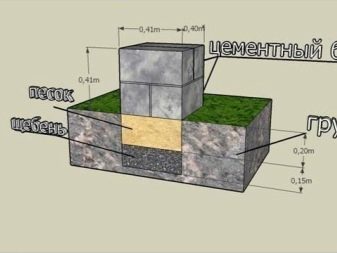

How deep the foundation pit should be is determined by the overall density and bearing strength of the soil. So, on top of fine sand or rocky rock, there is enough backfill of crushed stone over an additional sand layer, the thickness of which is 100-150 mm. It is necessary to strive to ensure that the proportion of the height of the column to its cross-section is minimal., this will immediately increase the stability of the building. The use of screened gravel barriers and geological textiles helps prevent water ingress even on very damp or watered soils.

The final decision on how deep and powerful the pillow should be is made taking into account the rigidity of the lower rims, and is also guided by the force of potential lateral shear. Longest thin pillars formed from asbestos-cement pipes are brought in deepest. But when ready-made reinforced concrete blocks are used, the surface dumping meets all the requirements. If you need to choose the simplest and most technologically advanced option, supports based on red ceramic bricks will be preferable... Under them, a pit is dug with a depth of not more than 250 mm, a pillow is poured and concreting of the supporting surface under a brick column is carried out; the surface should be 30 or 40% larger in area than the cross-section of the support.

The pillar-support foundations obtained by casting allow you to reduce costs, but at the same time you will have to put in more effort and wait longer for the result. The column is made using dismantled formwork, for which boards or chipboard are used. The mold used when pouring the column body is placed on a sand cushion with the addition of gravel with a total thickness of 0.1-0.15 m. ... Both the formwork and the reinforcement must be thoroughly aligned vertically using tension cords, then they are poured with heavy grades of concrete.

During the procedure, the incoming mass is compacted using manual rammers.When the pillar support is saturated with concrete to the upper plane, threaded rods or wire reinforcement are immediately introduced. The tops of the supports are covered with an insignificant layer of wet sand and covered with a film, achieving the appearance of cracks during solidification. On day 2-3, the outer surface of the pillar will reach the primary fortress, when another 5-7 days have passed, the formwork is removed, trim and level the supporting surface.

In the first 24 hours after dismantling the formwork, you must:

apply waterproofing coating;

use roll material to cover the lowered part of the support;

fill the gap from the concrete mass to the boundaries of the pit, first with expanded clay, and then with a combination of clay and sand.

If you need to build a light or moderately heavy house of foam concrete, a frame-type building, a reinforced concrete column foundation with a grillage is recommended. The role of this element is as follows: dispersion and transmission of loads falling on the walls to the piles, through which the energy is transferred into the soil.

Such a solution allows you to radically increase the stability and ensure the stable operation of the box at home for many years.

Since the grillage, except in cases with a buried design, does not come into contact with the soil, the threat of moisture damage and corrosion is extremely small. But at the same time, you still have to take care of waterproofing. The grillage formwork has a removable bottom, due to which the bottom surface is flat throughout.

The prefabricated monolithic grillage is formed using a metal I-beam or welded channel bars. The assembly of such a structure turns out to be very difficult, and in the literal sense, since the beams are very massive. In addition, we have to put up with the weakening of the welded joints compared to the main part of the beams. Therefore, in low-rise buildings, not this type is preferable, and not a more complex structurally prefabricated, but a monolithic grillage format.

If you plan to build a wooden building on top, it is recommended to use a shallow pillar foundation.

The advantages of this choice are:

minimum costs for the organization of earthworks (including due to the absence of the need for construction equipment);

the simplicity of the work itself;

saving on metal reinforcing rods (they are used, but in relatively small quantities);

construction speed even on soils prone to heaving;

excellent parameters in freezing soil.

As for the weaknesses, such a solution is incompatible with very loose soil, and it also does not work in wetlands.

In addition, if only minor defects appear, serious repairs must be carried out immediately in order to avoid further destruction of the building. To postpone the appearance of problems, reinforcement of monolithic parts of the foundation is carried out. This is the only solution available to private developers because they cannot produce prestressed concrete or other complex substructures.

As a result of the use of fittings:

significant stresses are transmitted from the surface to the deep layers;

provided, in the presence of a grillage, its impeccable bundle with the pillars;

the overall service life of the structure increases many times over in comparison with products not equipped with fittings.

You should not try to use ready-made calculation formulas to determine the rational parameters of the reinforcing mesh and its individual elements. Even qualified engineers will abandon this approach and use specialized software, because there are too many parameters to be taken into account and higher mathematics involved. Anyway, before contact with concrete, the reinforcing bars must be cleaned of all paints and varnishes, from traces of scale and corrosion.Additionally, anti-corrosion treatment is carried out using mixtures including phosphoric acid.

But everything that is said above refers mainly to concrete pillar structures. And along with them, brick foundation structures can be used. With the correct performance of the work, such a foundation will confidently serve 30 and even 50 years. For the foundations, an exceptionally full-fledged ceramic material in a red tone is selected. It is he who absorbs water least of all and turns out to be a very strong product.

It is recommended to take into account the information on the number of freezing and defrosting cycles.

It is unacceptable to use bricks with even small cracks. For masonry, strictly a solution of 1 part of cement and 3 parts of sand is used with the introduction of hydrophobic additives. For the sole of the base, pre-casting with concrete and filling is done, which helps to improve the subsequent use and strengthen the brick foundation.

Brick pillars should not be placed on weakened soils with pronounced horizontal mobility and where the height has differences from 2 m.

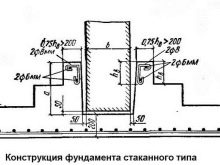

It is worth completing the story about the types of columnar foundations by describing the bases of the glass type. Its structure includes:

pit with sand or gravel filling;

plate;

column support element;

the columns themselves.

When everything is assembled, a foundation block appears with a wide base - 15-50 m² in most cases. Column nozzles are divided into prefabricated (built on site) and monolithic (installed as a single structure). Regardless of this gradation, installation of glasses on the ground prone to swelling and subsidence is not allowed.

Since all parts are prepared in an industrial production, they fully comply with the established norms and standards. Installation is greatly simplified and reliability is increased. But like all serial products, such a foundation is quite expensive and cannot be supplied without special equipment.

Dimensions (edit)

The dimensions of the columnar foundation from blocks 20x20x40 are calculated:

For the distances between the posts in the vertical and horizontal planes.

For the length of the reinforcement.

To determine the volume of concrete of the foundation itself and grillages. When all the parameters are determined, you just need to enter them into a special program and make a quick calculation.

The dimensions are determined in such a way that there is a safety margin of 20-40%. The increased stock is taken for buildings on intumescent soil.

It is recommended to immerse the foundation below the freezing line of the ground, which directly affects its size. The lower boundary of the pit for each post is 0.2 m lower than the foot of the post itself - this is important for backfilling sand. Monolithic reinforced concrete supports are from 0.3 m in size, from ceramic bricks - at least 0.38 m, laid out of stone - from 0.6 m.

Advantages and disadvantages

But before determining the size of the blocks and the consumption of materials, it is important to figure out whether it is worth choosing such a foundation at all. The columnar base is relatively inexpensive, but this is not its only advantage. The building will have a shallow draft and will reduce soil pressure by 20% or even slightly more. Therefore, the total area of the structure is reduced, which reduces installation costs. With all the advantages of a pole support, it will not be possible to put it under a heavy house, and exposure to horizontal shifts requires the use of solid grillages.

If we talk about the supporting-columnar foundation, it must be emphasized that it has the same positive and negative sides as other structures, even to a greater extent.

Even with high efficiency, such a support cannot be placed under a two-story building. It is also incompatible with the slightest disturbances in ground stability.

Using a grillage, you can increase the strength and stability of the foundation, reduce the need for earthworks, but you will have to pay more than when choosing a support-columnar scheme. Many positive and negative aspects directly depend on the materials used.

So, asbestos-cement pipes are easy to transport and install, but these cheap structures will require drilling wells in advance. Wood is the cheapest, but at the same time it serves very little, it is easily susceptible to fire, decay, extermination by gnawing insects and rodents. The brick turns out to be more durable, it is used well, the experience of its use is well worked out. In this case, the flaws of brick foundations are incompatibility with the swelling earth and high cost. Reinforced concrete is stronger than all other options, however, it is more expensive than them, it is very difficult to install and requires a significant amount of time.

Self-production

The practice generally accepted in the construction community provides that the calculation of the foundations of pillar foundations is carried out according to the sedimentary limit state (2nd category), and the building itself is calculated according to the 1st category. First, the engineering and geological parameters of the construction site are assessed, the depth of the foundation is assigned. Then it will be necessary to assess the size of the sole and the total mass of the structure, calculate the load and determine the amount of resistance.

It is imperative to check whether the conditions for calculating deformations are met; if necessary, the size of the sole is corrected. Additionally, it is checked how much the foundation will press on the upper line of the weak soil layer.

Even before drawing up drawings and diagrams, it is required to establish what the average draft is, what the amount of work should be.

All planned works and structures are compared with a typical case, a conclusion is made about the expediency of using an individual project. Explanatory notes must be attached to the drawings, showing all the nuances of future construction and justifying the decisions made. The distance from the foot of the pillar to the ground water can be at least 50 cm, since violation of this rule threatens to damage the main structures. For simplicity, the estimated depth of the foundation is rounded.

Construction

Do-it-yourself step-by-step instructions for building a pillar foundation provide for drilling holes for each unit supporting the building. Instead of permanent formwork filled with concrete, brickwork or prefabricated concrete structures are often used. The choice of this or that solution is determined in advance, even at the stage of calculations. In the presence of a grillage, a structure is installed that ensures the distribution of loads. It is formed from reinforced concrete, wood or steel parts. Next, waterproofing is performed, for which a profile sheet or siding is used.

Under a private house, no matter what grillage is made, the piles are brought under the freezing line. The marking of the terrain in accordance with the outlined plans is made using stakes. The usual support gap is 150-250 cm... They are placed not only under the intersections of internal walls, but also under all stoves and capital fireplaces. There is nothing complicated in all these works.

Repair

It is not enough just to pour the pillars under the house - sometimes they weaken over time and turn out to be less reliable, especially asbestos-cement pipes lose their characteristics quickly. They are often reinforced by converting a previously erected pillar foundation into a point structure with a shallow depth. Blocks that hold the house itself are laid, put them in 2 or 3 lines, holes are dug at the bottom about 150 mm deep, 2/3 of their height is filled with sand. From the upper blocks to the lower point of the house, waterproofing is formed from roofing material of an arbitrary brand.

When performing all operations, you need to be extremely careful to avoid clamping workers and other accidents.

The loss of its qualities by the columnar foundation is evidenced by:

the appearance of cracks;

difficulties in using windows and doors;

decay or corrosion in the lower portions of the walls.

The insulation of the columnar foundation deserves a special talk. If he got it together with a house already built earlier or has been in operation for a long time, it is necessary to clarify the data on freezing with the geologists. Most professionals believe that external insulation is preferable to internal insulation, because it protects the construction material from harmful mechanical influences and excessive moisture.

When choosing a heater, you need to focus not only on the level of thermal conductivity, but also on the specific gravity, on the tendency to soak in water.

Whether the foundation was built under a brick, wooden or other house, it is still insulated using a single technology.

Useful Tips

When a columnar foundation is laid out from blocks, the seams are subject to obligatory dressing. To increase strength, the voids are saturated with steel rods and mortar between them. With a depth of penetration of supports up to 1 m, it is possible not to strengthen the walls of the holes. If you plan to build a relatively heavy house, the diameter of the pipes is increased, the gaps between them are reduced. A grillage made of steel beams must be processed very carefully, otherwise corrosion will destroy it.

Do-it-yourself columnar foundation - in the next video.

The comment was sent successfully.