The process of making the foundation for the furnace

A real brick or "Russian" stove was and remains one of the main elements of the interior decoration of many private houses and buildings. For some people, it plays the role of an original design solution, for others it only serves as a heating function. One of the important points in its installation is the process of making the foundation.

Peculiarities

The installation of a serviceable and reliable stove has some features. For example, many developers or owners of private territories often wonder about the need to prepare a foundation or base for a stove. This means both costs and additional construction work - when it comes to buildings already built.

The following factors will allow you to understand for yourself whether it is advisable to install such a structure.

- Features of the soil / ground rocks. If you observe soil displacement, landslides, or the formation of holes in the rock in your area, the installation of a foundation is recommended. However, when installing a stove in a house with a monolithic / solid reinforced concrete base, this option is excluded.

- Design features of the building / structure itself. Here, factors such as the availability of free space for installation, the material at the base of the building (stone, wood, reinforced concrete) are important. In wooden houses with a brick stove without a foundation, there is a high risk of fire. Many types of bricks, such as porous clay bricks, retain heat for a long time.

- Estimated weight of the stove. If it does not exceed 200-250 kg, the installation of the foundation is optional. It is worth considering the load of the stove on the foundation of your building / structure. Evenly distributing the weight is like ensuring a long shelf life for both the stove and the base. Equal pressure on both components will reduce friction and the risk of rapid wear. Since most of the ovens are of the "Russian" type - oversized structures with a weight of up to several tons, this point is incredibly important.

Many have their own opinion on this issue, but experienced developers understand the need to install a foundation. This serves as an additional factor in the reliability and stability of the stove.

When installing the foundation, special attention should be paid to the type of soil in your territory:

- sandy loam;

- clayey;

- loam.

Since the installation of a stove in houses is most often not a one-time use (except for less demanding and easy-to-install metal stoves), you should take care of the safety of the foundation both at high and low temperatures - for summer and winter time.

Some types of clay-containing soils expand at low temperatures. In construction, this is called heaving, that is, the freezing of moisture in the rock. However, the expansion of the soil is often uneven and can lead to cracks and damage to the foundation.

There are a number of measures for greater reliability in the installation of the foundation. They are designed for responsible owners or developers with established safety standards (building a public place: a manor house, a museum, even a library).

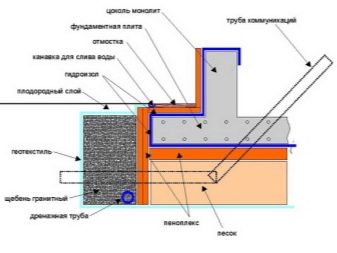

- Supplying the foundation with an additional slab. The slab is placed under the base of the foundation, occupies a large area and has the function of reducing pressure and load. High-quality reinforcement of the slab is recommended, this will reduce the risk of cracking.

- When installing the slab, it is advisable to use a special sandy loam cushion, which will perform the function of cushioning (taking pressure and loads) of the lower rocks when freezing.

- To ensure the complete safety of the building, it is possible to install drainage pipes or heating / thermal insulation of the building. This will reduce the possibility of excessive heaving.

This applies more to new buildings and structures under construction, but one should not think that the installation of an ordinary stove is so complicated and demanding.

Do not forget that a high-quality foundation for a stove is, first of all, safety for the whole house. The more quality efforts will be spent on its installation, the less additional costs in terms of time and resources for repair and dismantling will be.

Views

Weight, the presence of free space, the level of groundwater and the type of soil itself are the determining factors for choosing one or another type of foundation. You can find only a few types of foundations: tiled (or slab), piled, buried / not buried. Some still talk about this type as a strip foundation.

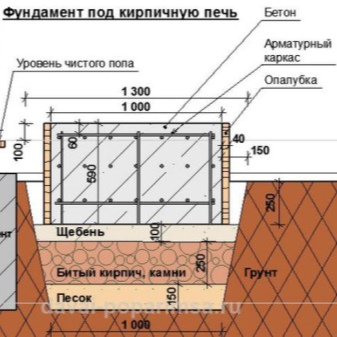

- Tiled the foundation requires the installation of a sandy loam cushion and crushed stone (up to 10 cm thick), poured with a concrete layer of no more than 5 cm, and reinforcing structures. They are installed to distribute the load evenly. A feature of a slab foundation is the solidity and integrity of a reinforced concrete / concrete slab. It is possible to place roofing material on bitumen, this will help the structure to maintain waterproofing.

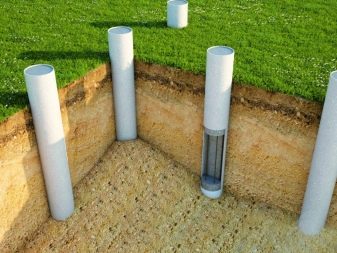

- The peculiarity of the pile foundation in simplicity and reliability. Its installation does not require additional earthworks - the piles can be driven into the ground by driving or vibrating. At the same time, piles can be made from both certain types of wood and reinforced concrete. Installation of metal hollow piles is possible - the structure allows itself to be driven deep into the ground and filled with concrete - for better stability.

This type is one of the most common in the construction of buildings and medium-sized objects.

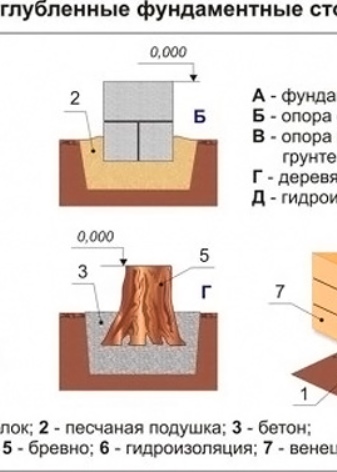

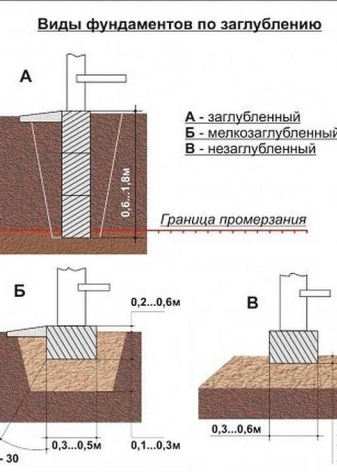

You can distinguish the type of foundation by its placement relative to the floor of the building / structure. There is a buried type and a non-buried one.

- Recessed is needed for brick ovens with a weight of 2 tons or more. The basis for this foundation is porous clay or loess soil. The latter is a rock of a sedimentary non-layered type, often a mixture of loamy and sandy loamy rocks. At the same time, do not forget that the depth of the foundation on these rocks should be below the freezing level in autumn or winter frosts.

- The use of the non-recessed type is justified for furnaces with a weight of no more than 1.5 tons. At the same time, it shows high characteristics of strength and reliability precisely in areas with a low level of groundwater and with continental or sedimentary ground rock.

Each of the types is used in different conditions at the construction site. Here you can say both about the weather conditions and about the finances spent on the installation.

How to build?

Making each type with your own hands is quite possible, stock up on the necessary literature and patience.

The first step in a tile installation is to prepare a groove in the soil for future installation. The dimensions and depth in this case are not fixed by anyone (although there are recommended dimensions - up to 500 mm), the developer must independently select the optimal characteristics.

The surface of the pit should be monitored, it must be flat.

The next stage is filling the pit with rubble (up to 10-15 cm) and tamping. You can fill in the finished solution after waterproofing the structure with roofing material. The composition of the filling in this case is 1/3/5 (cement, sand, crushed stone). Often this type is installed on the basement floors of small buildings.

A pile foundation or a foundation on screw piles is an equally reliable and easy-to-install type. For it, you will need to dig holes in the corners of the proposed slab (the diameter must remain at a level of at least 20 cm). The pits are pre-filled with moistened sand and gravel (from 10 to 15 cm) - it is necessary to do it for ease of tamping.

The preparation of the formwork for the further pouring of concrete requires the installation of a roofing felt sheet and an armored belt. After ramming, pouring and coating the piles, the latter are mounted with each other and serve as bases for reinforced concrete or concrete slabs. As already mentioned, there is a type of pile foundation without excavation.

An in-depth view is more difficult in design and installation. There is a sequential installation plan here.

- Make sure that the pit you dug is 10-15 centimeters larger than the dimensions of the stove itself. This figure must be observed on each side of the pit. Depth characteristics in this case are not fixed, everyone follows different rules, but most often it does not exceed one and a half meters.

- The next step is to compact and tamp the bottom of the excavated pit. For this, crushed stone can be used (pre-moistened or not - it's up to you). After compacting the bottom of the pit, the thickness of the crushed stone should not fall below 15 cm.

- For tighter compaction, the developer can use a sandy loam layer up to 30 cm thick, the latter moistened with a small amount of water for greater compaction. When the sand layer is dry, you need to add another layer of rubble on top of it. This time - already up to 20 cm.

- The next important step is to make wooden formwork. The inner surface can be pre-lubricated with bitumen, so you will provide waterproofing to your structure.

- Further installation of the buried view is similar to the installation of a pile foundation, however, the formed space from the walls of the soil to the foundation in this case is covered with sand.

The shallow type is represented by three separate types: columnar, monolithic slab, lattice. Each of these types has its own installation features.

- Columnar is a cheaper option and is presented in the form of several vertical supports, immersed in the prepared soil by no more than 30%. The approximate distance between the supports should be 2 meters.

- Monolithic slab more suitable for installing a foundation on soils without soil subsidence. But this type is applicable to lighter buildings, as it is subject to the influence of external factors - mechanical damage and others. Hydro- and heat-insulating elements can be brought under the finished monolithic slab - in order to avoid freezing in the winter season.

- Lattice type is, perhaps, one of the simplest types of unburied foundation. Making it involves mounting a large number of slabs with fittings. This will save your resources when pouring. In addition, the lattice type is more resistant to breakage. In case of breakage or formation of cracks in certain parts of the foundation, the risk of transmission of damage to another part of it is reduced.

Advice

As you can see, making the necessary foundation for the stove is a complex, but necessary process for the good operation of any heating system. There are a few simple, summarizing points that, if used correctly, you will competently organize any stove in your home.

- Define the parameters of your territory. These are: environmental conditions, possible mechanical damage, calculate the load and pressure from the stove. Conduct an in-depth analytical calculation - from your financial capabilities to measuring the level of groundwater. The more accurate the data, the easier it will be to choose the right type of foundation, and the less hassle it will bring you to operate it.

- Everyone has their own financial capabilities, but try not to save on equipment, solutions and mechanisms for high-quality filling.Remember, the price equals the quality, and the higher it is, the more chances that your installation will last a long time and will only bring you satisfaction and joy.

- Explore other resources, electronic and written, with quality foundation installation information. You should understand that someone who is knowledgeable is armed for emergencies. And experience is not only a matter of theory, but also of practice.

The process of building a furnace from laying the foundation, see below.

The comment was sent successfully.