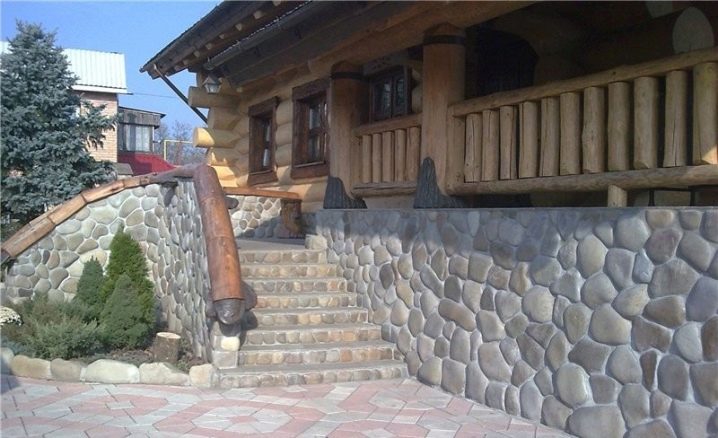

Rubble foundation: features and construction technology

The construction of buildings of any purpose and complexity is not complete without the work on laying the foundation. For this, various methods and materials are used. Among this list, it is worth highlighting the rubble foundation, which has been popular for a long time.

What it is?

It is the construction of the foundation that is the fundamental stage preceding all other construction work in the construction of houses or other structures. Despite the fact that a wide range of different materials is presented on the construction market, natural raw materials are still in demand. Natural building materials used for laying the foundation include rubble stone, which is a high-quality and environmentally friendly breed that has found its use in construction.

Some people mistakenly believe that the use of the stone is impossible during the laying of the foundation due to its irregular shape., however, even with minimal experience in construction, you can even competently equip the stone foundation of a building with your own hands.

It was such a foundation that, for the most part, builders preferred to erect in the recent past.

Nowadays, a concrete base for buildings increases their visual appeal., and most importantly, it allows you to carry out work on the arrangement with minimal costs, using a fairly simple technology for implementing a construction project.

As practice shows, the service life of a rubble foundation reaches about 150 years, there are even fortresses, during the construction of which this natural material was used. The main feature of rubble stone foundations is resistance to groundwater, as well as soil freezing.

Experts use several varieties of this raw material in their work:

- Industrial stone. They are engaged in its release in special complexes in which crushed stone is made. This type is in demand in the course of strengthening railway tracks or hydraulic structures.

- Rounded stone. The formation of such a breed occurs naturally.

- Bedding. It has an inherent irregular geometry, due to which the boot is in demand for laying the foundation, and also acts as a decorative material used in the creation of landscape design.

There are no strict requirements for the rubble rock used for laying the foundation of the structure, the main thing is that the raw material does not crumble.

It is best to use tiled or pastelis. Such material has smooth edges, which makes it easier to lay, since it will be much easier to place samples of the correct shape as tightly as possible to each other.

Analyzing the technology for erecting a foundation from rubble rock, we can say that the principle of its implementation is similar to the construction of brick walls - the components are placed on top of each other during laying, and the connection of all elements occurs when using mortar. The difference lies only in the materials and the composition used, which provides a bond - for a stone base, it is necessary to use a strong concrete mortar.

A standard strip rubble foundation is typically about 1.6 m high, with the base resting on a special sand and drainage pad.

The foundation is laid above the level of freezing of the soil, usually at a distance of about 30 centimeters, then the basement of the building and the basement are already located.

pros

Among the features of the rubble foundation it is worth highlighting its main advantages:

- The use of this rock allows you to build bases that will differ in height and strength. This is true for the construction of private houses with a large area.

- The raw material consists of natural components, therefore it belongs to the group of materials that do not pose a danger to human health. In addition, the material is environmentally friendly.

- Bases made of rubble stone stand out for their durability and reliability, since the rock has excellent strength indicators.

- Such designs are resistant to wear and tear.

- The material can be used to build the foundation of any house, with different shapes and areas.

- Reinforcement for such bases is rarely required.

- The stone is resistant to moisture, so the base does not collapse from the effects of melt or groundwater.

- Cross-sectional cobblestones are a very attractive material.

- The breed can be combined in work with other building materials. In some cases, the part of the base that protrudes to the surface is erected from brick, and the rest, which is located in the ground, is equipped using rubble stone. This method, according to experts' reviews, makes it possible to save on construction work.

- The base of the rock has high resistance to negative temperatures.

- It is noteworthy that the rubble foundation practically does not need to be repaired, since defects do not form on it over time.

Minuses

Foundations made from this material also have disadvantages.

These include the following points:

- Since the stone is a natural raw material, its cost is quite high.

- To carry out the preparatory work preceding the construction of the foundation, it is necessary to calculate the amount of material required, which requires certain qualifications and experience. All technology for arranging the base should be carried out in accordance with SNiP, in addition, it is necessary to measure the level of occurrence of groundwater in a given area.

- The whole process of laying stones is done by hand.

- It is quite difficult to lay out the breed of irregular shape in an even structure.

- At the base of rubble stone, bond erosion can occur - during the penetration of water into the cement mortar, with its further freezing, the concrete is destroyed, and the destroyed sand grains of the material are blown out of the base by the wind, which leads to destruction.

- In case of violations in the calculations of the strength of the foundation and the weight of the structure, it may be necessary to reinforce the base. It is also necessary in areas where there are signs of soil mobility.

Device

The laying work is preceded by preparatory measures for the arrangement of trenches, as well as sorting of rubble - it must be divided based on size. To reduce the time spent on laying the rock, a wooden formwork is arranged in the trench against each other, which can be adjusted in height.

The construction of a stone foundation can be done in two ways:

- direct method - which involves pouring concrete into the trench with a layer thickness at which the rock will be half buried in it;

- the opposite option - in this case, the first layer of rubble is poured with cement mortar, which hides it to the maximum, after which the subsequent layers of stone are laid.

Before backfilling, most builders advise spreading a layer of polyethylene with a high level of strength on a sandy pillow.

It will allow you to preserve the properties of the solution, without giving out the cement laitance. The rock is laid in two parallel lines with a gap for mortar between the elements of about 5 centimeters. The top row should be laid in such a way that the stones overlap the seams of the bottom row.

In order for the solution to be suitable in strength, cement M 500 should be used for its preparation. The density of the composition should allow it to freely penetrate into the seams between rubble cobblestones. Before laying, it is advised to moisten the stone a little to remove dust, which will have a positive effect on adhesion to the solution.

How to do it?

When performing work on the construction of a rubble foundation, you should follow the step-by-step instructions, as well as purchase all the necessary materials and tools:

- sand and crushed stone;

- cement;

- stone rock;

- container for solution;

- bayonet shovel, trowel;

- building level;

- plumb line and rammer.

Crushed stone will be used to fill the voids that arise during the laying of stones, sand is needed to prepare the solution, as well as to equip the pillow below, even if the foundation is shallow. The smaller the boot, the more it will be needed for the base. In addition, waterproofing will be required for the work. Roofing material or any other product can be used as such material.

The technology of laying rubble foundation includes the following works:

- Trench device. It is worth noting that its width should be at least 2.5 meters. Such a need is due to the large size of the breed. The base tape will turn out to be about 0.5-0.6 m.

- On the inside of the tape, an indent of about 0.7 m is left, on the outside - 1.2 m. This feature will help in work on moving the formwork. The outer gap is filled with sand.

- For concreting with the laying of rock, the formwork must be carried out in dimensions corresponding to the height of the building basement.

- The inner surface of the boards is covered with a film that will prevent the concrete solution from flowing through the existing gaps between the planks. In addition, it will prevent the wood from absorbing moisture from the composition.

Rubble stone is laid according to the following scheme:

- after laying the film on the bottom, the solution is poured;

- two rows of stones fit on it, elements of similar size should be selected;

- then a layer of solution is poured, which must be leveled;

- bandaging is performed on the outer or inner side with a butt row;

- after that, the laying is performed in longitudinal layers;

- the corners of the structure are tied with rock.

During work with the solution, it is necessary to control the filling of all existing voids.

So that there are no untreated areas left, it is important to prepare a plastic mixture for work.

To increase this indicator, various additives are used, for example, plasticizers for concrete or detergents.

Concreting the foundation with a stone is performed according to the following scheme:

- a layer of concrete is poured onto the bottom of the trench, its thickness should be about 300 mm;

- after which the stone is laid, the rock layer should be 200 mm;

- to immerse the rock in the composition, you must use a reinforcing bar or a special tool;

- the remaining 500 mm of the base are poured without rock placement. Steel rods are used to reinforce the structure.

Advice

Experts with many years of experience in their practice actively use useful algorithms for performing certain processes that allow them to optimize the progress of tasks. Such advice should be adopted by less experienced builders.

There are a number of practical recommendations, thanks to which you can significantly facilitate independent work on the construction of a rubble foundation on your own:

- the arrangement of gentle slopes in the trenches under the base will provide a more comfortable working area for pouring the foundation, since this feature will accelerate the supply of rock and mortar;

- the inconvenience associated with steep slopes can be solved by installing wooden scaffolding;

- in the side parts of the trenches that are shallow, it is worth placing containers in which the cement-sand composition will be located, and between them you can make blanks from stones of the required size;

- before carrying out work on pouring the foundation, it is worthwhile to calculate and mark in advance the places where communications and ventilation will be laid, which will shorten the period for carrying out work on the arrangement of the base;

- all calculations of the amount of materials required for the work must be carried out before the foundation is poured, since a violation of the technology for performing work can lead to negative consequences that will affect the quality of the foundation made of rubble stone;

- natural cobblestones, which have the most even edges, will act as a support for the entire base and structure, therefore, they must be carefully pressed into the bottom of the trench, making sure that they do not sway and are located along the trench, and not across. Therefore, a very important stage in the work is the sorting of rubble into fractions.

For the basics of laying rubble stone, see the video below.

The comment was sent successfully.