Bored foundations with a grillage: technical characteristics and scope

The foundation is the main part of the entire building, bearing the entire load of the structure. Structures of this type are of several types, which allows them to be used on various types of soil. Particular attention should be paid to foundations with a grillage with unique technical parameters. In this article, we will get acquainted with such systems in more detail, and also consider several types of such foundations.

Design features

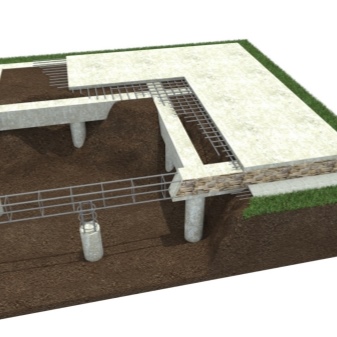

Bored foundations with a grillage are foundations for residential or industrial buildings. Such a structure consists of several basic elements.

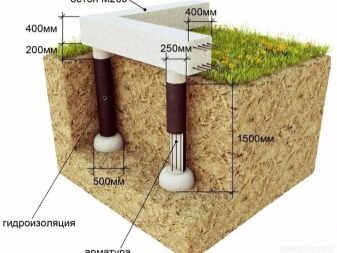

- Supports. They are a kind of piles made from metal or asbestos pipes. Inside, the system is filled with concrete, which is the main component of the structure. The diameter of the support can be varied in a wide range, which allows you to change the technical characteristics of the product to suit your personal needs.

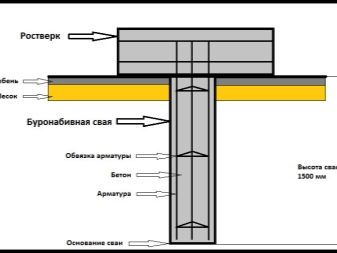

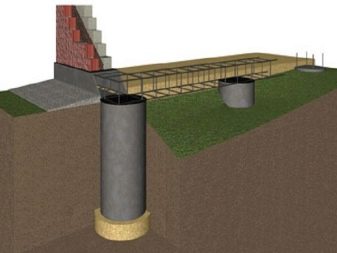

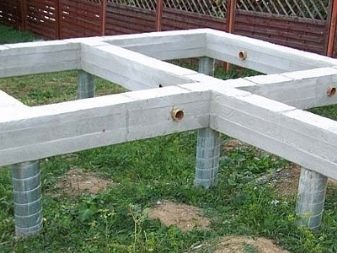

- Grillage. The device of this element is quite simple. The grillage is a kind of jumper connecting all vertical supports. Many materials are used as such frames. The bases with a monolithic grillage have gained particular popularity. The lintel here assumes a concrete band, which is also connected to the supporting elements. From above it turns out something like a strip foundation.

Bored foundations are made on the basis of special SNiP, taking into account the operating conditions.

It should be noted that structures of such a plan can be easily operated on various types of soils.

The pitch of each pile is determined based on the mechanical loads that will be applied to the foundation. Please note that the grillage can be located both at a short distance from the ground and go deep into the soil.

Purpose

Bored foundations are especially popular today, as they differ in good technical parameters and ease of construction. They are used as bases for small-sized construction. Often, on the basis of bored foundations, one-story residential buildings are erected from foam concrete, wood or brick.

The practicality of such a system is also in its independence. With the help of a pile foundation, it is quite easy to attach an additional building to the house. In this case, there is no need to use the same type of base as under the main structure.

Technically, almost any lightweight structure of any shape and complexity can be placed on bored foundations. But in most cases it is used precisely in residential construction, where there is no need to use heavy monolithic slabs or powerful tapes.

Very often, bored foundations are found on swampy or peaty soils. This is due to the fact that the support layer capable of withstanding loads is located quite deep in the ground (up to 8-10 m). It is technically very difficult and economically unprofitable to build a strip or monolithic slab foundation under such conditions.

Views

Bored-type foundations perfectly absorb loads, distributing them along the entire perimeter. The main element of this system is the grillage. Depending on the location of the tape, the bases are divided into several types.

- Recessed. The top line of the grillage is placed inside the ground. Its upper part is in the same plane with the soil. Technically, the entire tape is hidden underground.

- Ground. The lower part of the grillage is located directly at the ground level. Outwardly, it looks like the tape is lying on the ground. It is recommended to build ground and buried foundations only on persistent soils. In other cases, these structures can be negatively affected by the soil, resulting in consistent and relatively rapid destruction.

- Raised. Technically, the grillage is raised on supports above the ground. It turns out that there is an air gap under this element. The lifting height can be different, depending on the purpose of the element. Raised foundations are used in most cases on heaving soils, characterized by instability.

Another criterion for classification is the type of grillage, which is of two types.

- Tape. A grillage of this type is a tape, the width of which corresponds to a similar parameter for future walls. Technically, the structure is located around the entire perimeter and follows the contours of the house.

- Plate. Externally, it is a solid slab covering the entire area of the future house. In most cases, structures are made of concrete. Monolithic structures withstand and distribute the load well. There are also prefabricated grillages, which are formed from special metal frames or other materials.

Foundation strapping can be carried out using several types of materials:

- timber;

- rolled metal products;

- reinforced concrete structures.

Advantages and disadvantages

Pile foundations are especially popular among many professionals. Such designs have several positive features.

- High performance indicators. Structures of this type are perfect for brick houses with an impressive mass. To extend the service life of such a system, it is important not to forget about waterproofing when building it.

- Local impact on the ground. During the construction of vertical supports, there is no impact on adjacent buildings or elements. This makes it possible to erect foundations even close to constructed structures.

- Possibility of installation in various conditions. Technically, you can drill a hole for a pile even in fairly dense soil layers.

- Ease of construction. It is not difficult to build a frame, especially if you have special equipment. This reduces the amount of work, since it is not necessary to form a trench from which a lot of soil is removed.

- Construction is carried out directly at the construction site. This procedure can be accelerated by using a concrete mixer, which allows you to prepare the required volume of concrete.

The only drawback of bored foundations is the impossibility of using them for multi-storey buildings. This is due to the fact that they are unable to withstand very heavy loads. Therefore, according to user reviews, the systems should be used to form the basis of private houses, which, with such a foundation, can serve for a very long time.

Filling technology

The construction of bored foundations is not difficult. However, it is important to comply with technical standards. This will allow you to obtain a system that can withstand loads without loss of bearing parameters for a long time.

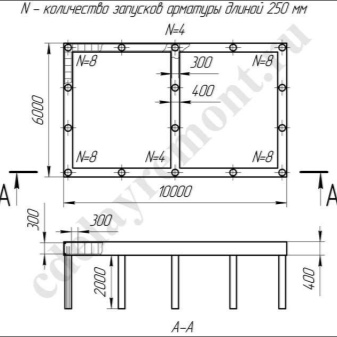

A simplified algorithm is used to calculate the technical parameters of the foundation.

- The first step is to calculate the total weight of the building. This is quite simple to do. For this, the amount of materials that will be used in the construction of walls and roofs is taken. After that, for each substance, the specific gravity is specified and the mass is calculated based on the previously obtained volume.

- The next step is to find out the snow loads. Their average values are indicated in special summary tables of SNiP No. 01.07.The resulting indicators must be added to the previously calculated total mass of the house.

- The operational loads are then calculated. To find them out, multiply the total floor area by a factor of 100 kg / m2.

- The process ends with the calculation of the total load on the foundation. Initially, all the numbers obtained in the previous stages are summed up, and then the result is multiplied by the reliability factor. You can find it out in the special technical documentation.

The minimum distance between the support posts should be no more than 2 m.

If this indicator is increased, then this can lead to rapid wear or cracking. Experts recommend using concrete grade B15-B20 as a material. At the same time, when pouring piles, it is advisable to use more durable analogues (B20) in order to obtain a stronger and more durable structure.

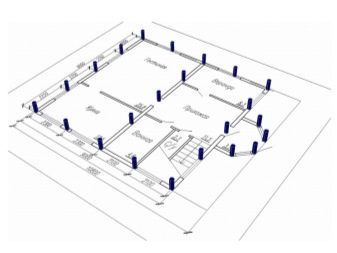

When placing supports, it is important to evenly distribute them around the entire perimeter of the future building. The support pillar must be placed at the edge of each line and at their intersections (corner points).

The technology for constructing a bored foundation with your own hands involves the implementation of mandatory sequential operations.

- Site preparation. To simplify the work, the top layer of soil should be removed. After that, the site is marked. This is easier to do with pegs or wooden planks. You just need to control the corners of each side to get rectangular elements without distortions. These operations are often easier to control with diagonally stretched threads.

- Making holes. The procedure begins with drilling holes for piles. This process is carried out using special drills. Devices can be either manual or engine powered. The drilling depth is determined theoretically or practically during the preparatory step. This will let you know how far away the reference layers are.

- Casting of supports. The bottom of the dug hole is initially cleaned of loose soil and thoroughly rammed. Then the surface is covered with coarse and medium sand, which forms a kind of pillow. Its thickness can reach 30-50 cm, depending on the structure of the soil. After that, the formwork is placed in the drilled channel. It can be used as a metal pipe, steel sheet and so on. After that, reinforcement is placed inside the hole. It is pre-welded into a kind of rigid frame. Such reinforcement will give concrete a higher strength and resistance to dynamic loads. When the frame is ready, the pipe is poured with the previously prepared concrete. This technology can only depend on the amount of work.

- Construction of the grillage. The construction process begins with the installation of the formwork. For this, wood is used. If the grillage is planned to be raised, then additional supports must be provided. They will hold the frame with the concrete until it hardens.

When the formwork is ready, a reinforcing wire frame is also placed inside it. To connect these elements, metal should be left outside in the support pillars. The procedure is completed by pouring the formwork with concrete. Please note that the pouring procedure should be carried out at one time. Thus, you will get a monolithic structure that will be much stronger and more reliable.

If the construction of the foundation is carried out on coarse soils, then the grillage can be placed directly on the soil itself. In another case (heaving soils), experts recommend additionally forming a layer of sand. It will extend the life of the grillage with constant exposure to temperature changes.

Bored foundations with a grillage are a unique structure that can significantly reduce the cost of forming reliable foundations. During the construction of structures, technical standards should be adhered to.Therefore, all these tasks should be solved only by experienced specialists who have the appropriate professional equipment.

During the construction of structures, technical standards should be adhered to. Therefore, all these tasks should be solved only by experienced specialists who have the appropriate professional equipment.

The following video will tell you about the features of piles with a grillage.

The comment was sent successfully.