Foundation blocks: varieties and characteristics, recommendations for laying

Any construction activities for the construction of buildings and structures begin with the preparation of the foundation. The reliability and durability of the entire building will depend on its quality. The construction market offers many materials for this important task. In order to get a good result in a short time without unnecessary costs, additional preparation, without using formwork, experts suggest using foundation building blocks, abbreviated as FBS.

What it is?

Foundation blocks are basically concrete. They are designed to speed up the process of laying the foundation.

FBS have a wide range of applications:

- construction of foundations for residential and industrial buildings;

- construction of basements and cellars;

- construction of various supports, flyovers and bridges;

- construction of garages and basements;

- installation of barriers.

When using high-quality material, the block foundation will be durable and reliable.

Dimensions (edit)

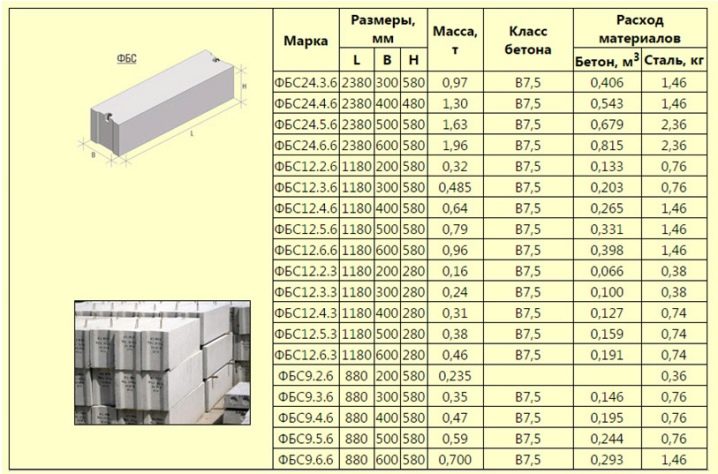

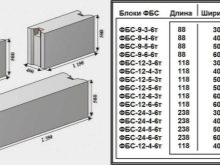

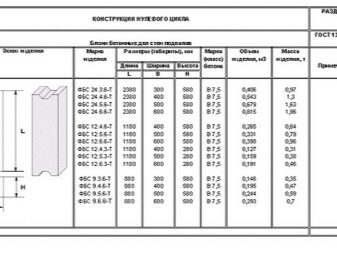

The dimensions of the foundation blocks are regulated by GOST. As a rule, in the designation of the standard size, the length, width and height are indicated immediately.

Standard

Traditionally, forms for FBS are rectangular parallelepipeds, however, products of an individual format can be ordered.

On the sides, the blocks have end grooves that provide a good packing density.

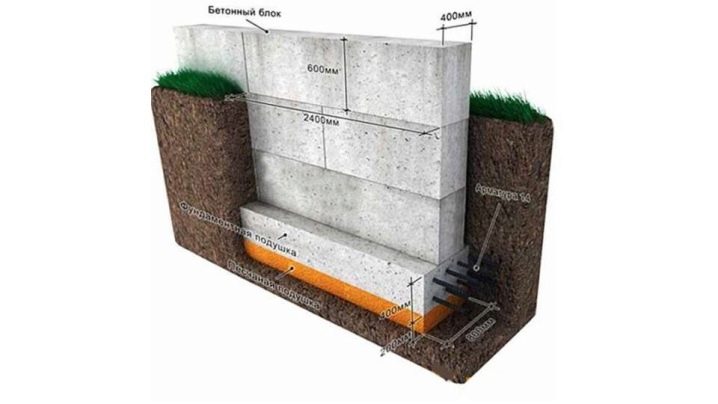

The most common and popular model has dimensions of 2400 x 400 x 600 mm. Moreover, the length is rounded up, since in fact the standard is 2380 mm.

In addition to those indicated, foundation blocks with a length of 1180 and 880 mm are in demand. In this case, the width can be from 300 to 600 mm in increments of 100. The standard height, as a rule, is 580 mm (rounded up 600 mm).

Small-sized

According to GOST, blocks are also produced with small dimensions, 40 and 60 cm long. Such FBS are used for non-standard designs. For example, builders often use 200 x 200 x 400 mm (20 x 20 x 40 cm) heavy concrete structures for low-rise buildings, and can be laid by hand without the use of special equipment. And also they will be indispensable for the construction of a foundation on sandy soil. Such a block weighs an average of about 31 kilograms.

And also small-sized products include blocks with parameters 600 x 600 x 600 and 400 x 400 x 200 mm. They are used as wall for the construction of basements and cellars, as well as for the construction of a columnar type of foundations.

When choosing parameters, it is necessary to focus on the type of soil. With a low degree of soil stability, more massive blocks are used. For example, FBS with a length of 2400 mm is laid on clay soil, and small-sized options are laid on sandy soil.

Standards

All technical characteristics of the FBS are also regulated by GOST.

In addition to the dimensions, the standard indicates the mass of the unit. This indicator determines the density of concrete, as well as the weight, the knowledge of which is necessary for loading, transportation and laying.

Dimensions and weight must be consistent. The deviation is permissible, but insignificant. So, the maximum permissible deviation of length should not exceed 13 mm, width and height - 8 mm.

If the weight established by the standard for a particular model differs significantly from the original, then the block has unacceptable internal voids, which reduces its strength. Such models cannot be used for the construction of structural structures.

It also indicates for the construction of which structures this or that type is suitable. For example, using the knowledge of the standard, you can accurately calculate how deep the foundation should be for a one-story house.

For the production of any type of foundation block, high density concrete must be used.

Its class determines the strength of the FBS:

- T - heavy concrete, density about 2400 kg / cu. m;

- P - expanded clay concrete, density 1800 kg / cu. m;

- С - silicate concrete, density 2000 kg / cu. m.

Manufacturers are obliged to indicate all characteristics in the labeling. For example, if FBS-24-4-6 t is indicated in it, then a block with parameters 2380 x 400 x 580 is used, in the production of which heavy concrete was used.

In addition to standard parameters, GOST regulates such as frost resistance and thermal conductivity.

For those who are not knowledgeable in the field of building materials, it is necessary to clarify that the higher the coefficient of thermal conductivity, the less heat is retained. Such blocks require insulation.

The frost resistance index behaves the other way around. The higher the coefficient, the higher the material's resistance to freezing.

Other parameters that are stipulated by GOST include fire resistance and water resistance.

Views

The classification of the foundation blocks depends on the conditioning factor.

By material type

According to GOST, a structural type of raw material is used in the production of foundation blocks: several types of concrete mixtures of high density.

- Concrete, cement or reinforced concrete. For strength, granite or basalt chips are added to the latter. FBS, in the production of which heavy grades of concrete are used, have the maximum density. The main advantage of reinforced concrete is the durability and strength of the entire structure.

- Silicate. The manufacturing technology is similar to the production of bricks. Some brands provide additives in the form of high-grade cement, but not more than 14 percent of the total. For strength, the solution is heated and then slowly cooled. This procedure provides one hundred percent strength gain.

- Expanded clay concrete. Blocks containing expanded clay in their composition have a permitted strength set of 70 percent. Such products belong to the class of lightweight concrete materials and are used for manual laying.

- From foam concrete. It should be noted that there are many building materials that have a similar production technology with FBS, but they cannot be used for the construction of the foundation. For example, experts do not recommend the use of gas silicate products without external protection, since porous materials have the ability to absorb vapor. This process leads to cracking of concrete at low temperatures. Without waterproofing, a foam concrete foundation can only be erected for technical premises: sheds, garages. In this case, the frame should not be greatly deepened.

- Previously, throughout the Soviet space, a cinder block was widely used. It was used in different qualities: for walls, for foundations. Its production was secondary in all metallurgical industries, since blast furnace slag was used for its production. Nowadays, additives in cinder blocks can be different: sand, gravel, crushed stone, broken brick or construction waste concrete, perlite, sawdust.The technical characteristics of the product depend on the additives. As a rule, cinder blocks have an uneven unsightly surface, but are extremely cheap.

Silicate and expanded clay materials have increased adhesion, therefore, with their help, structures of complex shapes are erected.

To use them as foundation blocks, the original mass is subjected to special processing.

- Silicate solutions are saturated with additives from ground blast-furnace slag, which leads to an increase in the waterproofing of the block.

- During molding, a vibration compaction procedure is used, in which excess air inside the mixture is removed, closing access for subsequent penetration of steam and water.

- Treatment of blocks with hydrophobic solutions. Usually these are organosilicon preparations characterized by a deep penetration coefficient.

By technology

Solid or corpulent. This modification, in turn, is divided into reinforced versions and blocks without reinforcement.

Such modifications are intended for supporting structures.

- Since the foundation is under constant compressive stress, solid reinforced blocks are the most demanded option for its construction.

- Hollow. As a formwork, it is convenient to use FBS hollow models. Reinforcement is placed in the existing holes and poured with concrete. And also similar products are used for the construction of lightweight types of foundations.

- With cutouts. Such blocks are often made on an individual order for laying communications for a specific project. End grooves provide a solid structure.

By surface type

Foundation blocks can either have a surface that cannot be covered with decorative materials, or they can be finished.

Deep cracks are not allowed on block edges. Permitted parameters are 0.1 mm for heavy and silicate type of concrete, 0.2 mm when used in expanded clay.

By form

FBS are available in two main formats.

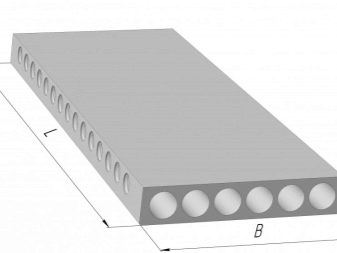

- Plate. If the foundation is being erected on soft ground, then special FBS, which are called "pillow", are indispensable for the first row. These building products have a large area of one of the surfaces, which increases the stability of the structure. Such slabs are officially called "for strip foundations" (FL). They are designed to ensure uniform shrinkage of the entire structure.

- Block. For all other types of soil, a block type is suitable, dimensions may vary.

By appointment

Manufacturers produce foundation blocks that differ in their technical characteristics. They are not interchangeable, so you need to be careful when choosing them.

The following types can be distinguished:

- wall;

- foundation;

- basement.

By way of increasing strength

Foundation blocks gain strength in different ways.

- Drying. The process consists in the natural drying and hardening of the concrete after shaping. For this, the blocks are kept for several weeks in a ventilated room.

- Steaming. Unlike the first method, steaming takes less time, for example, a day, to reach the standard hardness level of 70%. In this case, the FBS is under the influence of high pressure at high air humidity.

The quality of the products is practically indistinguishable, but the cost of the second method is higher.

Manufacturers overview

Any concrete plant in Russia has a line for the production of FBS. Unfortunately, not all of them produce quality products. Someone violates the technology, somewhere they add concrete of different brands to the solution, written off from other construction sites.

When choosing, you need to proceed from the purpose of the planned building. If these are technical buildings of small size, then you can save money by buying a cheap block. But in the case of a capital construction, especially a residential one, you should contact reliable suppliers specializing in the production of FBS.

Several domestic factories can be distinguished.

OJSC "Factory of industrial building parts". The production is located in the city of Surgut and is one of the largest in Russia. Reinforced concrete products are subject to strict quality control. The laboratory for improving the quality characteristics is accredited by the State Construction Committee of the Russian Federation. All manufactured products are certified.

The main types of products are:

- road plates;

- piles of several types;

- well rings;

- foundation blocks.

LLC TC "Vira" in St. Petersburg produces more than 400 types of ready-made concrete products. The firm produces construction products that can provide any type of construction from scratch. The company's regular customers are domestic enterprises of the Leningrad region and the entire North-West region of the Russian Federation. Partner contacts have been established with suppliers from near and far abroad.

High grade concrete is used for the production. All products have quality certificates and technical data sheets.

The developed logistics network allows the company to regulate prices, offering favorable conditions to regular customers. In addition, the plant provides advice on the selection, operation and makes the necessary calculations of consumables.

Main products:

- aerated concrete blocks;

- ceramic brick;

- roofing materials;

- a natural stone;

- siding;

- flexible stone;

- reinforced concrete products, including foundation blocks.

The company offers solid foundation blocks for the construction of strip-type foundations. The overall dimensions are varied: from 2400 x 500 x 600 to 380 x 190 x 190 mm. For their manufacture, heavy grades of concrete are used.

LLC "Master" - a young fast-growing company from Voskresensk. The company produces a wide range of products for the construction segment, including foundation blocks.

- Large-sized FBS with a length of 2400 and a height of 600 mm. Width varies from 300 to 600 mm in increments of 100.

- FBS for walls and basements, for which the height remains unchanged 600 mm, the proposed length options are 2400, 2200, 900, 800, 500 mm, modifications in width are similar to large-sized products.

- Slabs for strip foundations are represented by a huge list of products.

- Foundation beams, differing from blocks with a substantial length of up to 6000 mm.

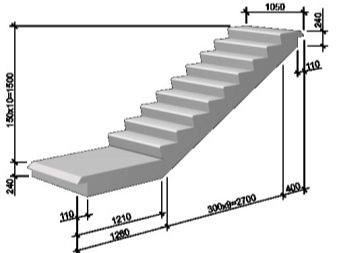

The company also produces floor slabs, stair flights, reinforced concrete piles, power transmission poles, columns, supports, fences and much more.

All goods have the necessary supporting documentation. LLC "Master" is engaged not only in the production and delivery of goods to the customer, but also provides installation services.

LLC "Aleksinsky expanded clay plant". The plant is located in the Tula region and has been operating since 1985. The main activity is the production of expanded clay and products made from it, including wall foundation blocks.

The undoubted advantages are the development of our own technologies, high professionalism of employees, multi-stage quality control.

Foundation expanded clay concrete blocks have the following technical characteristics:

- concrete strength grade - heavy;

- density 2100-2300 kg per cubic meter;

- strength according to GOST M150-M200;

- filler - sand and gravel mixture;

- dimensions 390 x 190 x 188 mm;

- weight in the range of 27-29 kilograms;

- does not conduct current;

- the absence of radioactivity is confirmed by a certificate;

- water absorption up to 7%.

LLC "Zlatoust plant"located in the Chelyabinsk region produces a wide range of standard building materials. In addition, it accepts individual orders.

The quality of products is carried out by our own accredited laboratory. The use of high-tech equipment and in-house developments in the field of technology allows the company to improve the quality characteristics of its products.

All products comply with GOST, have supporting documentation in the form of certificates, licenses, guarantees and technical passport.

A well-developed logistics network allows us to offer our regular customers favorable terms.

Among the large number of products offered there are foundation blocks, both large-sized with a length of 2400 mm and small-sized ones with a length of 600 mm.

Advantages and disadvantages

Like any building material, FBS has its own characteristic pros and cons.

Let's start with the merits.

- Shortened foundation installation time. The filling version reaches the required strength level after an average of 4 weeks.

- Simplicity of calculations due to standard dimensions.

- Reduced cost of formwork and reinforcement.

- Possibility of choosing foundation blocks with specified technical characteristics, for example, frost resistance or moisture resistance.

- Long service life.

- Resistant to deformation.

- Wear resistance.

- Environmentally friendly in most cases.

- Corrosion resistant.

- FBS are not subject to decay.

- Uniform shrinkage and load distribution.

- Absence of rejects associated with a violation of filling or reinforcement. Subject to the choice of a high-quality, certified unit.

- Precise geometric shape.

- Reducing the number of manual operations.

- Large assortment of sizes.

- Versatility. The same types can be used in private and industrial construction, for walls and for foundations.

- Work can be carried out all year round, regardless of weather conditions.

Disadvantages:

- unlike the bulk version, the foundation of building blocks has joints that must be insulated;

- installation of the foundation using large-sized blocks will require the involvement of construction equipment for lifting and laying;

- not all types of foundations can be built using FBS, for example, for high-rise buildings;

- poor thermal conductivity requires insulation of the foundation from the blocks.

How to choose?

Before purchasing foundation blocks, you need to familiarize yourself with their technical characteristics and find out about the manufacturers who produce them in the region.

You need to focus on the following factors:

- the climate of the region;

- type of soil;

- number of storeys and height of the building;

- planned thickness of walls and floors;

- total weight of the structure;

- base area.

Before purchasing, it is necessary to make the correct calculation of consumables: blocks and cement mortar. Many firms offer this as a bonus on purchase.

For industrial construction, large-sized foundation blocks made of concrete of heavy grades are used.

For the construction of private buildings such as cottages or garages, small-sized reinforced concrete blocks are used.

For a summer cottage with a frame made of lightweight building materials: wood or foam blocks, it is inappropriate to spend money on a solid foundation, in this case, you can use lightweight foundation blocks made of silicate or expanded clay concrete. Lightweight FBS can be laid manually without the use of special equipment. Blocks with parameters 20 x 20 x 40 cm will be appropriate here.

For a gazebo or utility room, you can choose aerated concrete.

In addition, when choosing, you need to pay attention to the manufacturer.

- It is better if the blocks are factory-made, since in this case they undergo multilevel quality control and comply with GOST.

- A reputable manufacturer will not only provide the entire package of documents, but also offer a guarantee or calculate the consumption of materials.

- For the construction of residential or large-sized structures, it is better to purchase blocks with a margin of safety, for example, reinforced.

If the production technology is not violated, then the FBS will last a long time (up to 50 years). The exception is blocks with blast furnace slag additives. These products deteriorate over time, and do not get stronger, since the slag decomposes over time.Therefore, this type of FBS can be purchased only for temporary or technical buildings.

An important characteristic when choosing is the geometric shape of the FBS. Ideal geometry will optimize grout consumption and finishing costs. And also it will improve the quality of the connecting seams. Ceramic blocks and foam concrete have the best indicators in this regard.

If we consider all the characteristics in aggregate, then the most advantageous in terms of price-quality ratio are expanded clay concrete products and foam concrete. At a relatively low cost, they have high coefficients of frost resistance, excellent energy-saving properties, and good durability.

The most eloquent factor when choosing is the reviews of those who have already used the specified material, but within reason.

Working with material

The technology for working with foundation blocks is similar to the method of laying bricks or cinder blocks. The only difference is size and speed. Installation of structures with the help of FBS is faster, therefore they are preferred to be used for the construction of industrial facilities.

Features of working with a foam block

A characteristic feature of foam concrete products is low rigidity. The foamed variation, in contrast to the monolithic one, is characterized by increased elasticity and is subject to shrinkage. Foam concrete blocks are inappropriate as foundation blocks in cases with a heavy frame of the structure itself. Under load, they shrink significantly, which can cause the walls to buckle.

Experts advise in this case to use steel reinforcement to redistribute the load.

Project

Any construction begins with a project that contains all the information about the structure. It includes drawings of each floor and foundation, communication diagrams, calculation of material consumption and much more.

Based on this, you can determine the type of foundation blocks and calculate their number.

Base drawings should contain information about the presence of basements, basement floors or their absence. The methods of laying the foundation depend on this.

Based on the project, you can order individual blocks with a couple of holes for communications.

Preparation of laying foundation blocks includes several operations.

Markup

The design layout will help to mark the foundation. To do this, pegs are driven into the corners of the site, which was determined for the construction. A rope is pulled between them and an intermediate wall marking is additionally installed.

Pit

You can lay out any foundation with your own hands, but for this you need to competently prepare the pit, focusing on the type of soil.

The depth of the pit for a conventional foundation, as a rule, is equal to the depth of soil freezing plus 20 centimeters... But this rule is feasible only for temperate climates. In cold regions, the amount of freezing is much higher. Digging so deeply is labor-intensive and expensive, so in this case we limited ourselves to a depth of 1 - 1.5 meters.

The dimensions of the pit, in the event that a deepened foundation is planned, should be wider, better by 1 - 1.5 meters. This distance is necessary to carry out work on waterproofing and thermal insulation.

If the foundation silicate blocks are deepened by 50-60 cm, and the estimated height of the structure is 2 - 3 block rows, then it is possible not to expand the working area.

Sole

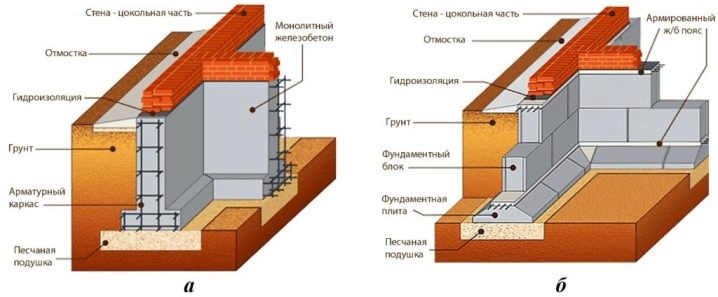

To equip the foundation, they use two methods.

- On a sandy pillow. Previously, in a dug trench, the bottom is leveled, clay and peat are removed. Next, coarse gravel is poured and carefully tamped, gradually adding fine gravel and sand. The next step is to lay out drainage flooring and geotextiles.

- On a concrete base. After compaction of the soil, the formwork is assembled from the boards around the entire perimeter of the foundation. Next, fittings are laid. For its manufacture, steel rods with a diameter of 12 to 14 mm are used.They are tied with a metal wire in a mesh with cells of 10 or 15 cm. Depending on the number of storeys of the structure and its dimensions, the reinforcing layers can be from two or more. After preparation, the base is poured with concrete. Pouring should be done slowly and evenly, expelling excess air. The surface is aligned with the rule. The foundation cushion should dry and gain strength only after 3 to 4 weeks. In hot weather, moisten it with water to avoid cracking.

Other

In order to navigate the foundation perimeter, even in bad weather, you should take care of the wooden flooring.

Styling

The next step is the laying of foundation blocks. The FBS must be placed neatly and individually.

Influence of soil

Laying the foundation with FBS is possible on all types of soil.

If the ground cover is weak, viscous, crumbling, then it is necessary to strengthen the supporting structure with reinforcing belts every two rows.

For stable types of soil, the installation of an intermittent foundation is shown, in which the blocks should be laid at intervals of no more than 70 cm. The voids are filled with earth and well compacted. This option is less expensive. It is prohibited to erect multi-storey buildings on such a foundation.

On weak types of soil, it is better to lay out the first row with pillow blocks.

Instead of burying the foundation blocks in the ground, you can assemble the columnar version from the blocks. Such a structure is suitable for buildings made of lightweight aerated concrete or wood concrete slabs. To make a basement floor, foam blocks and piles are combined.

First row

The reliability, strength and geometric accuracy of the construction largely depends on whether the laying of the first row of FBS is done correctly.

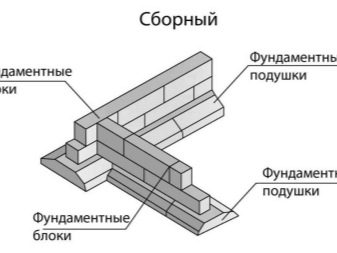

More often, the initial preparation consists in leveling the horizon, that is, it is planned to install FL slabs to increase the support area and uniform shrinkage of the heavy foundation.

Laying the first row begins from the corners, after which a control measurement of the height is carried out with a building level or level. Then a cord is pulled between the corner blocks to make it easier to lay out the intermediate parts. Foundation blocks are fixed with cement mortar. It is better to fit the FBS to each other with a rubber mallet.

When the mortar has set, reinforcement is carried out, if necessary.

Further installation is recommended only after some time, when the cement is completely hardened. If you start laying out the next rows earlier, then there is a great risk of deformation of the initial row.

Installation of foundation blocks

When erecting industrial buildings or structures, large blocks are used, for the laying of which a construction crane is required.

For small-sized construction, special equipment is not required, since you can cope on your own.

Laying begins in the same way as the first row: from the corners. Then intermediate blocks are attached. For fastening, a cement mortar is used, and vertical joint joints are filled with it.

Installation technology is similar to brickwork. The seams of the previous and subsequent rows must not match. Geometry must be constantly monitored using a level for this purpose. It is important that the foundation has the correct shape.

Waterproofing

Foundation blocks, especially porous ones, must be treated with hydrophobic solutions. Most often, experts cover the entire masonry with liquid mastic. It is necessary to smear with it not only the outer, but also the inner surfaces of the foundation.

If the climate in the region is humid, then you need to take care of additional waterproofing. For this, roofing material is used.

Reinforced Belt

Some experts recommend reinforcing the top foundation row. This is especially true in those areas where the soil is unstable, which causes the "walking" of the soil.

Reinforced concrete reinforced belt is designed to strengthen the base of the structure. Floor slabs are laid on it.

Before pouring, a wooden formwork is installed around the entire perimeter. For reliability, the boards are fastened with wire. Steel reinforcement with a section of 10 mm is laid inside the box. Then the entire structure is poured with concrete.

Construction can be continued after the armopoyas has completely solidified.

Useful Tips

- At the design stage, it is necessary to obtain an opinion from a geodetic company about the peculiarities of the soil on the site. This is necessary in order to resolve the issue of the possibility of using foundation blocks for construction, as well as the choice of methods for laying the foundation. In addition, this report indicates the depth of the groundwater, which is also necessary for the construction of the foundation.

- For residential construction, it is better to choose factory-made blocks, since such products are under the control of experts.

- The worse the bearing capacity of the soil, the larger the FBS should be.

- According to the recommendations of the builders, the base of the foundation should be located below the level of soil freezing.

- Fine-grained expanded clay as part of the foundation blocks will provide the correct geometric shape, and will also distribute heat evenly.

- For prefabricated foundations, it is better to use reinforced concrete FBS.

- It is better not to buy handicraft blocks for the construction of residential buildings, since a violation of technology during production can lead to the destruction of the entire building.

- The longer the block length, the fewer joints, which means more reliable.

- Reinforced concrete blocks have a safety margin of up to 70 percent, which eliminates cracks.

- The foundation silicate blocks should be treated with hydrophobic substances after laying. If you do this earlier, the strength of the installation will be violated, since the binder solution will not be absorbed well.

Liquid mastics or bitumen are best suited for waterproofing a foundation.

However, experts use other methods:

- pasting with roofing material;

- painting with special paint based on acrylic, silicone or polyurethane;

- plastering with polymer compounds;

- hydrophobic additives that are added to the concrete, making the entire block waterproof;

- spraying a thin rubber layer.

It is easier and cheaper to lay out a columnar foundation using FBS. But it should be borne in mind that it is not suitable for the construction of a two-story house. This option is more appropriate for the construction of greenhouses, gazebos and light frame houses.

Wall blocks can be used as foundation blocks only in low-load buildings.

It is necessary to carefully tamp the base cushion under the foundation, constantly wetting it, which will prevent the structure from "walking".

When calculating the consumption of materials, the weight of the structure must be taken into account. To do this, it should be remembered that the volume of concrete of different models may be different depending on the density.

When calculating, it is also necessary to lay down the purchase of several blocks with cutouts for laying communications. Otherwise, you will have to drill holes in the purchased FBS.

If you need to build a strip foundation for the fence, then to save money, it is recommended to use used blocks. The main thing is that there are no chips and significant cracks on them. It is estimated that the cost savings in this case will be from 30 to 50 percent. FBS, used, also suitable for gazebos, small greenhouses and temporary technical structures.

All about the block foundation and the intricacies of construction, see this video.

The comment was sent successfully.