Subtleties of the strip foundation reinforcement process

Any building cannot do without a reliable and solid foundation. The construction of the foundation is the most important and time consuming step. But in this case, all the rules and requirements for strengthening the foundation must be observed. For this purpose, a strip foundation is being erected, which is able to make the foundation of the structure strong and reliable. It is worth considering in more detail the features of the strip foundation, as well as the technology for performing the reinforcement of the structure.

Peculiarities

The strip foundation is a monolithic concrete strip without breaks on the doorways, which becomes the basis for the construction of all walls and partitions of the structure. The basis of the tape structure is a concrete mortar, which is made of cement grade M250, water, sand mixture. To strengthen it, a reinforcing cage made of metal rods of different diameters is used. The tape extends a certain distance into the soil, while protruding above the surface. But the strip foundation is exposed to serious loads (movement of groundwater, massive structure).

In any situation, you need to be prepared for the fact that various negative influences on structures can affect the state of the base. Therefore, if the reinforcement is performed incorrectly, at the first slightest threat, the foundation may collapse, which will lead to the destruction of the entire structure.

Reinforcement has the following advantages:

- prevents soil subsidence under the building;

- has an affirmative effect on the soundproofing qualities of the foundation;

- increases the resistance of the foundation to sudden changes in temperature conditions.

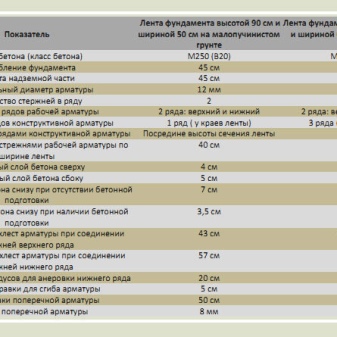

Requirements

Calculations of reinforcing materials and reinforcement schemes are carried out in accordance with the rules of the functioning SNiPA 52-01-2003. The certificate has specific rules and requirements that must be met when reinforcing a strip foundation. The main indicators of the strength of concrete structures are the coefficients of resistance to compression, tension and transverse fracture. Depending on the established standardized indicators of concrete, a specific brand and group is selected. Performing the reinforcement of the strip foundation, the type and controlled indicators of the quality of the reinforcing material are determined. According to GOST, the use of hot-rolled construction reinforcement of a repeating profile is allowed. The group of reinforcement is selected depending on the yield point at ultimate loads; it must have ductility, resistance to rust and low temperature indicators.

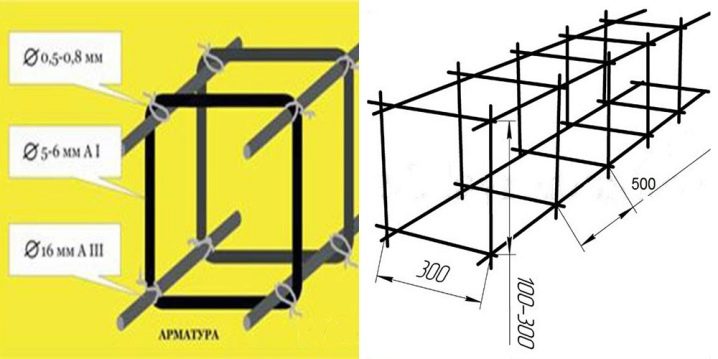

Views

To reinforce the strip foundation, two types of rods are used. For axial ones that carry a key load, class AII or III is required. In this case, the profile should be ribbed, because it has better adhesion to the concrete solution, and also transfers the load in accordance with the norm. For superconstructive lintels, cheaper reinforcement is used: smooth reinforcement of class AI, the thickness of which can be 6-8 millimeters. Recently, fiberglass reinforcement has become in great demand, because it has the best strength indicators and long operating periods.

Most designers do not recommend using it for the foundations of residential premises. According to the rules, these should be reinforced concrete structures. The features of such building materials have long been known.Specialized reinforcing profiles have been developed to ensure that concrete and metal are combined into a coherent structure. How concrete with fiberglass will behave, how reliably this reinforcement will be connected to the concrete mixture, and also whether this pair will successfully cope with various loads - all this is little known and practically not tested. If you want to experiment, you can use fiberglass or reinforced concrete reinforcement.

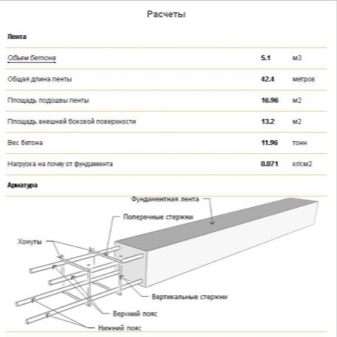

Payment

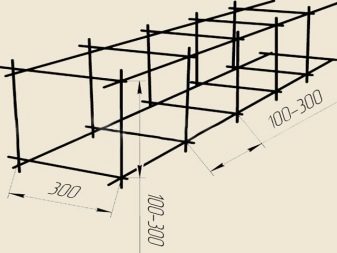

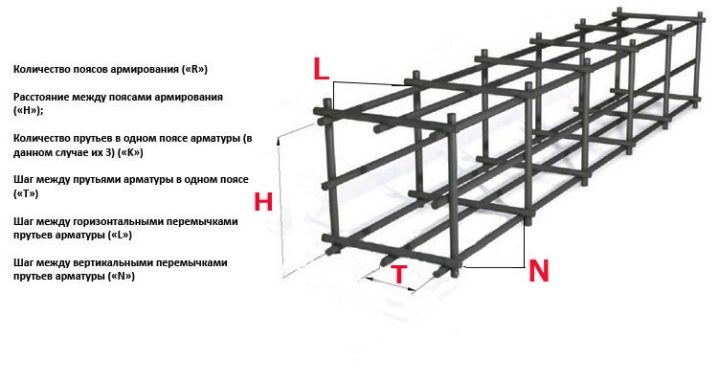

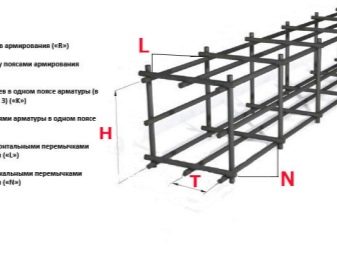

The consumption of reinforcement must be carried out at the stage of planning the foundation drawings in order to know with accuracy how much building material will be required in the future. It is worth familiarizing yourself with how to calculate the amount of reinforcement for a shallow base with a height of 70 cm and a width of 40 cm.First, you need to establish the appearance of the metal frame. It will be made of upper and lower armored belts, each with 3 reinforcing rods. The gap between the rods will be 10 cm, and you also need to add another 10 cm for the protective concrete layer. The connection will be carried out with welded sections from reinforcement of identical parameters with a step of 30 cm. The diameter of the reinforcement product is 12 mm, group A3.

The calculation of the required amount of reinforcement is performed as follows:

- in order to determine the consumption of rods for the axial belt, it is necessary to calculate the perimeter of the foundation. You should take a symbolic room with a perimeter of 50 m. Since there are 3 rods in two armored belts (6 pieces in total), the consumption will be: 50x6 = 300 meters;

- now it is necessary to calculate how many connections are required to join the belts. To do this, it is necessary to divide the total perimeter into a step between the jumpers: 50: 0.3 = 167 pieces;

- observing a certain thickness of the enclosing concrete layer (about 5 cm), the size of the perpendicular lintel will be 60 cm, and the axial one - 30 cm. The number of a separate type of lintels per connection is 2 pieces;

- you need to calculate the consumption of rods for axial lintels: 167x0.6x2 = 200.4 m;

- consumption of products for perpendicular lintels: 167x0.3x2 = 100.2 m.

As a result, the calculation of reinforcing materials showed that the total amount for consumption will be 600.6 m. But this number is not final, it is necessary to purchase products with a margin (10-15%), since the foundation will have to be reinforced in the corner areas.

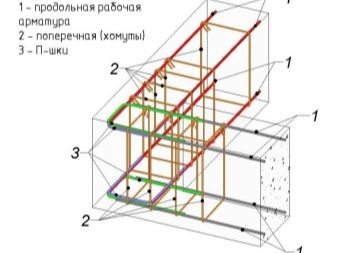

Scheme

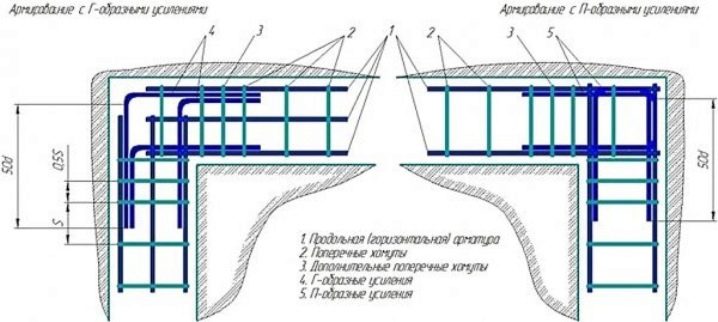

The constant movement of the soil puts the most serious pressure on the strip foundation. In order for it to firmly withstand such loads, as well as to eliminate sources of cracking at the planning stage, experts recommend taking care of the correctly selected reinforcement scheme. The foundation reinforcement scheme is a specific arrangement of axial and perpendicular bars, which are assembled into a single structure.

SNiP No. 52-01-2003 clearly examines how the reinforcement materials are laid in the foundation, with what step in different directions.

It is worth considering the following rules from this document:

- the step of laying the rods depends on the diameter of the reinforcing product, the dimensions of the gravel granules, the method of laying the concrete solution and its compaction;

- the step of working hardening is a distance that is equal to two heights of the cross-section of the hardening tape, but not more than 40 cm;

- transverse hardening - this distance between the rods is half the width of the section itself (no more than 30 cm).

When deciding on the reinforcement scheme, it is necessary to take into account the fact that a frame assembled into one whole is mounted into the formwork, and only the corner sections will be tied inside. The number of axial reinforced layers should be at least 3 along the entire contour of the foundation, because it is impossible to determine in advance the areas with the strongest loads. The most popular are schemes in which the connection of reinforcement is performed in such a way that cells of geometric shapes are formed.In this case, a strong and reliable foundation is guaranteed.

Work technology

Reinforcement of the strip foundation is carried out taking into account the following rules:

- for functioning fittings, rods of the A400 group are used, but not lower;

- experts do not advise using welding as a connection, since it dulls the cross section;

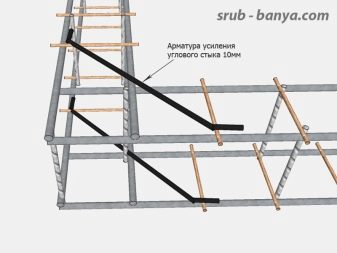

- at the corners, the reinforcement is bound without fail, but not welded;

- for clamps it is not allowed to use threadless fittings;

- it is necessary to strictly carry out a protective concrete layer (4–5 cm), because it protects metal products from corrosion;

- when making frames, the rods in the axial direction are connected with an overlap, which should be at least 20 diameters of the rods and at least 25 cm;

- with frequent placement of metal products, it is necessary to observe the size of the aggregate in the concrete solution, it should not get stuck between the bars.

Preparatory work

Before starting work, it is necessary to clear the working area from various debris and interfering objects. A trench is dug according to the previously prepared markings, which can be done manually or with the help of specialized equipment. To keep the walls in a perfectly level condition, it is recommended to install the formwork. Basically, the frame is placed in the trench along with the formwork. After that, concrete is poured, and the structure is waterproofed by means of roofing felt sheets without fail.

Reinforcement knitting methods

The hardening scheme of the strip foundation allows the connection of the rods by the bundling method. The connected metal frame has an increased strength in comparison with the welding version. This is because the risk of burning through metal products increases. But this does not apply to factory products. It is allowed to perform reinforcement on straight sections by welding to speed up work. But the corners are reinforced only with the use of knitting wire.

Before knitting reinforcement, you need to prepare the necessary tools and building materials.

There are two ways to bond metal products:

- specialized hook;

- knitting machine.

The first method is suitable for small volumes. In this case, the laying of reinforcement will take too much time and effort. Annealed wire with a diameter of 0.8–1.4 mm is used as a connecting material. The use of other building materials is prohibited. The reinforcement can be tied separately, and then lowered into the trench. Or, tie the reinforcement inside the pit. Both are rational, but there are some differences. If made on the surface of the earth, then you can handle it yourself, and you will need an assistant in the trench.

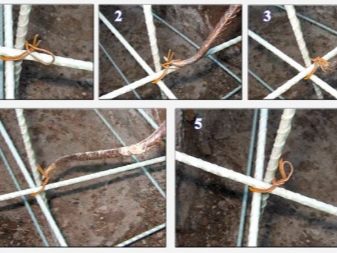

How to correctly knit reinforcement in the corners of the strip foundation?

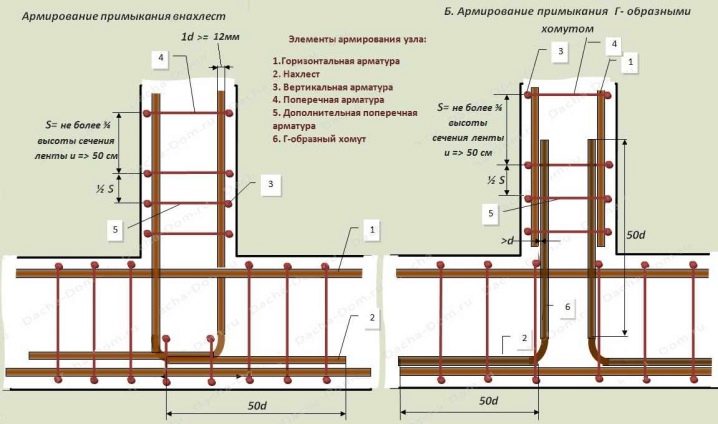

Several binding methods are used for corner walls.

- With a paw. To carry out work at the end of each rod, a foot is made at an angle of 90 degrees. In this case, the rod resembles a poker. The size of the foot must be at least 35 diameters. The folded section of the rod is connected to the corresponding vertical section. As a result, it turns out that the outer rods of the frame of one wall are attached to the outer ones of the other wall, and the inner ones are attached to the outer ones.

- Using L-shaped clamps. The principle of execution is similar to the previous variation. But here it is not necessary to make a foot, but a special L-shaped element is taken, the size of which is at least 50 diameters. One part is tied to the metal frame of one wall surface, and the second to the vertical metal frame. In this case, the inner and outer clamps are connected. The step of the clamps should form ¾ from the height of the basement wall.

- With the use of U-shaped clamps. At the corner, you will need 2 clamps, the size of which is 50 diameters.Each of the clamps is welded to 2 parallel rods and 1 perpendicular rod.

How to properly reinforce the corners of the strip foundation, see the next video.

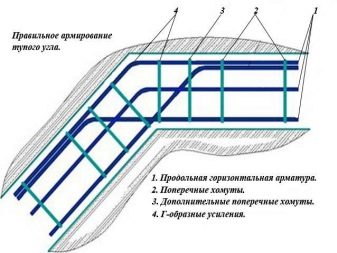

How to reinforce obtuse corners?

To do this, the outer bar is bent to a certain degree value and an additional rod is attached to it for a qualitative increase in strength. Internal special elements are connected to the external one.

How to knit a reinforcing structure with your own hands?

It is worth considering in more detail how the knitting of reinforcement on the surface of the earth is performed. First, only straight sections of the mesh are made, after which the structure is installed in the trench, where the corners are reinforced. Reinforcement sections are being prepared. The standardized size of the rods is 6 meters, if possible it is better not to touch them. If you are not confident in your own abilities that you can cope with such rods, they can be cut in half.

Experts recommend starting to knit reinforcing bars for the shortest section of the strip foundation, which makes it possible to acquire a certain experience and skill, in the future it will be easier to cope with long structures. Cutting them is undesirable, because this will lead to an increase in metal consumption and reduce the strength of the foundation. The parameters of the blanks should be considered using the example of a foundation, the height of which is 120 cm and the width is 40 cm. Reinforcement products must be poured from all sides with a concrete mixture (thickness about 5 cm), which is the initial condition. Given these data, the net parameters of the reinforcing metal frame should be no more than 110 cm in height and 30 cm in width. For knitting, add 2 centimeters from each edge, this is necessary for overlap. Therefore, workpieces for horizontal lintels should be 34 centimeters, and workpieces for axial lintels - 144 centimeters.

After calculations, the knitting of the reinforcing structure is as follows:

- you should choose a flat piece of land, put two long rods, the ends of which need to be trimmed;

- at a distance of 20 cm from the ends, horizontal spacers are tied along the extreme edges. To tie, you need a wire of 20 cm in size. It is folded in half, pulled under the binding site and tightened with a crochet hook. But it is necessary to tighten carefully so that the wire does not break off;

- at a distance of about 50 cm, the remaining horizontal struts are tied in turn. When everything is ready, the structure is removed to the free space and another frame is tied in an identical way. As a result, you get the upper and lower parts, which need to be connected together;

- next, it is necessary to install stops for two parts of the mesh, you can rest them against various objects. The main thing is to observe that the connected structures have a reliable profile location, the distance between them should be equal to the height of the connected reinforcement;

- at the ends, two axial spacers are tied, the parameters of which are already known. When the frame product resembles a finished fixture, you can start tying the remaining pieces of reinforcement. All procedures are performed with checking the dimensions of the structure, although the workpieces are made of the same dimensions, an extra check will not hurt;

- by a similar method, all other straight sections of the frame are connected;

- a gasket is laid at the bottom of the trench, the height of which is at least 5 cm, the lower part of the mesh will be laid on it. Side supports are installed, the mesh is mounted in the correct position;

- parameters of unconnected joints and corners are removed, sections of the reinforcement product are prepared for connecting the metal frame to the general system. It is worth noting that the overlap of the ends of the reinforcement should be at least 50 bar diameters;

- the lower turn is tied, after the perpendicular racks and the upper pivot is tied to them. The distance of the reinforcement to all the faces of the formwork is checked. The strengthening of the structure ends here, now you can proceed to pouring the foundation with concrete.

Knitting reinforcement using a specialized device

To make such a mechanism, you will need several boards 20 millimeters thick.

The process itself looks like this:

- 4 boards are cut off according to the size of the reinforcing product, they are connected by 2 pieces at a distance equal to the step of the vertical posts. As a result, you should get two boards of an identical template. It is necessary to ensure that the marking of the distance between the rails is the same, otherwise the axial arrangement of the connecting special elements will not work;

- 2 vertical supports are made, the height of which should be equal to the height of the reinforcing mesh. The picks should have profiled corner supports to prevent them from toppling over. The finished structure is checked for strength;

- the legs of the support are installed on 2 knocked-down boards, and the two outer boards are placed on the upper shelf of the supports. Fixation is performed by any convenient method.

As a result, a model of the reinforcement mesh should be formed, now the work can be carried out without outside help. Vertical braces of the reinforcement product are installed on the planned sections, in advance by means of ordinary nails for a certain time, their position is fixed. A reinforcement rod is installed on each horizontal metal lintel. This procedure is performed on all sides of the frame. If everything is done correctly, you can start knitting with a wire and a hook. The design must be done if there are identical sections of the mesh from the reinforcement product.

Knitting reinforced mesh in trenches

It is quite difficult to carry out work in the trenches due to the tightness.

It is necessary to think carefully about the knitting pattern for each special element.

- Stones or bricks with a height of no more than 5 cm are laid at the bottom of the trench, they will raise metal products from the surface of the earth and allow concrete to close reinforcement products from all edges. The distance between the bricks should be equal to the width of the grid.

- Longitudinal rods are placed on top of the stones. Horizontal and vertical rods must be cut according to the required parameters.

- They begin to form the base of the frame on one side of the foundation. The work will be easier to perform if the horizontal spacers are tied to the lying rods in advance. An assistant should support the ends of the bars until they are mounted in the desired position.

- The reinforcement is knitted alternately, the distance between the spacers must be at least 50 cm. The reinforcement is connected in a similar way on all straight sections of the fundamental tape.

- The parameters and spatial location of the frame are checked, if necessary, it is necessary to correct the position, and also to exclude the touch of metal products to the formwork.

Advice

You should familiarize yourself with the multiple mistakes that inexperienced craftsmen make when performing reinforcement without observing certain rules.

- Initially, it is necessary to develop a plan, according to which calculations will be performed to determine the load on the foundation in the future.

- During the manufacture of the formwork, no gaps should form, otherwise the concrete mixture will flow through these holes and the strength of the structure will decrease.

- It is imperative to perform waterproofing on the soil; in its absence, the quality of the slab will decrease.

- It is forbidden for the reinforcement rods to come into contact with the soil, such contact will lead to rust.

- If it is decided to reinforce the frame by welding, then it is better to use rods with the C index.These are specialized materials that are intended for welding, therefore, under the influence of temperature conditions, I do not lose my technical characteristics.

- It is not recommended to use smooth rods for reinforcement. The concrete solution will have nothing to gain a foothold, and the rods themselves will slide in it. When soil moves, such a structure will crack.

- It is not recommended to arrange corners by means of a straight intersection, reinforcement products are very difficult to bend. Sometimes, when reinforcing corners, they come to tricks: they heat a metal product to a pliable state, or with the help of a grinder, they file down structures. Both options are prohibited, because with these procedures, the material loses its strength, which in the future will lead to negative consequences.

A well-performed strengthening of the foundation is a guarantee of a long operational life of the building (20–40 years), therefore, special attention should be paid to this procedure. But experienced craftsmen advise to carry out maintenance and repair work every 10 years.

The comment was sent successfully.