All about gable trim

Every owner of suburban real estate has to think about how to sheathe the pediment of the roof of a house cheaper and beautifully. Many people manage to create original design solutions from quite budget materials. How to make scaffolding for work, to make cladding with your own hands, will help you to find out a detailed overview of finishing options, how to implement them.

Peculiarities

Sheathing of the pediment of a private house, bathhouse, garage, attic is carried out outside the building - along its facade, before or after the installation of a shed or gable roof. This term denotes the space bounded by the roof slopes on the sides and the cornice at the base. The shape of the pediment can be triangular, polygonal, circular. In fact, it is part of the wall of the building along the facade, but it does not have to have the same design as the main part of the building. The pediment is always located under the eaves of the roof, going deep under its edges.

Such walls on 2 sides of the facade cover the ends of the attic or attic space. They can be cold or insulated, complemented by rounded and arched dormer windows.

Depending on the features of the chosen construction method, the cladding is performed according to the following options.

- On the frame structure. In this case, the exterior finish is formed along the boards of the truss trusses, in the horizontal or vertical direction. Ventilation windows are required. It is advisable to perform cladding using natural materials, similarly making out the overhangs of the roof. Impregnations, paints and varnishes help protect wood finishes from weathering.

- On a solid wall. In this case, finishing is carried out using various materials, from sheets of drywall and corrugated board to polycarbonate, block house. The pediment itself is already formed from logs, beams, foam blocks or bricks. It is sheathed exclusively for decorative purposes - in the process of reconstruction or in order to improve the aesthetics of the facade structure.

The pediment requires preliminary design. When constructing it, wind loads, climatic features of the region, and the intensity of precipitation must be taken into account.

What can be sheathed?

The desire to decorate the pediment of the building cheaper and beautifully is quite understandable. When building a house, the cost of materials is already quite high. That is why the owners are trying to save money on finishing. Disputes about the best way to close the gable of the building are ongoing regularly. A complete overview of all types and options of cladding for this part of the facade will help you make a decision.

Wood

Edged and unedged planks are most often used in gable trim. It has sufficient bearing capacity, allows you to arrange inside thermal insulation or do without it. If you need not just to create a wooden pediment, but also to make it aesthetically pleasing, take the lining. It allows not only straight horizontal or vertical laying, but also to create patterns. In addition, carving is often used as decoration, which makes it possible to give the design uniqueness and aesthetics.

Such cladding has many advantages.

- Simplicity and speed of installation.

- Ease of care. The material perfectly tolerates atmospheric influences after processing with decorative and protective compounds.

- Variety of widths and lengths.You can select the optimal standard sizes for each building.

- Versatility. This finish is suitable for a country cottage and town house.

For cladding the gable, it is better to choose a class A lining, without defects, the most resistant to atmospheric factors. It is aesthetic, lends itself well to coloring and other methods of decoration. Natural wood is one of the most popular finishing options for carved and smooth gables. Such an architectural and design solution meets all safety standards, does not require complex maintenance, and can be easily equipped with your own hands.

Block house

Finishing panels that imitate the rounded surface of a log are well suited for decorating the gables of buildings and structures. Fastening of planks made of polymeric materials, most often from PVC, is carried out on a light frame. This design does not make the facade of the building heavier, it turns out to be strong and durable. The block house is available in a wide range of sizes and colors, does not lose its brightness under the influence of atmospheric factors. Externally, it completely imitates a log finish, it is suitable for covering the gables of not only residential buildings, but also baths, utility and commercial buildings.

Brick

During the capital construction of buildings, the pediment is most often made of brick - from the same material as the supporting structures and floors. When installed in corners, the material is specially cut for a more snug fit to the roofing "pie". Masonry is carried out using a reinforcing mesh, usually not exceeding 1/2 of a brick in thickness. A supporting wooden rail is installed in the center, going to the very ridge of the roof, cords are pulled from it to ensure the formation of the correct geometric structure.

Shingles

An effective solution that can be successfully implemented in work with both soft roofs and classic ceramic, cement tiles. Installation is carried out on a solid rough surface. The difficulty in working with the material lies in its vertical stacking.

The strength of the attachment is very important in this case. At the same time, the finished finish looks very aesthetically pleasing, emphasizes the uniqueness of the design solution in the design of the building facade.

Professional list

For cladding the gable, a wall variety of this material, marked with the letter "C", is used. Usually, not galvanized, but polymerized profiled sheet with a painted surface is used. The material is suitable for summer cottages and outbuildings; it is rarely used in residential buildings. The advantages of the profiled sheet include good bearing and covering ability, relatively low weight. But such a pediment requires additional sound insulation, insulation, and is not highly aesthetically pleasing.

Ondulin

It is used for cladding the gables of chalet or half-timbered buildings, allowing you to give a wooden structure an unusual, exotic look. Ondulin is mounted exclusively on a solid rough cladding (made of plywood, OSB), with an overlap, ensuring the formation of a coating from the required number of sheets. The color scheme of the material is varied, allowing you to choose the appropriate design for any building or structure.

Siding

Ready-made solution for finishing the gable - vinyl or metal siding. Thin decorative panels are mounted on a lightweight frame. Among their obvious advantages are:

- variety of design options;

- wide range of colors;

- the presence of texture;

- ease of installation;

- light weight.

Siding is considered the best choice for the design of gables in an urban, modern style. The material does not lose its properties for many years, it is resistant to weathering. With proper installation, you can not be afraid of warping the finish, loss of its functionality over time.

Other materials

There are also quite a few other materials used for sheathing gables. Among the common options are the following.

- OSB and plywood. They are used only for rough cladding of the gables of frame structures. On top of sheet materials, it is possible to attach additional lathing, finishing elements. In a country house, such a pediment can simply be coated with paint or varnish.

- Sheet polycarbonate or plastic. This option is used in temporary or seasonal structures, in the arrangement of art workshops. A translucent material lets in a lot of light. Sheets are attached to special profiles to create stiffeners.

You can use colored polycarbonate, honeycomb or monolithic.

- Planken panels. This special type of façade board is created on the basis of hardwood. It is used in the decoration of houses from timber, logs, in the restoration of old buildings. The material is mounted similarly to siding, with a gap for possible deformation under the influence of moisture, atmospheric temperatures.

- Glass. Warm or cold rooms of the house under the roof can be designed using panoramic glazing from 1 or 2 sides. In this case, custom-made multilayer frame structures with original joining are used. Such a design solution requires professional installation, but gives a lot of light, avoids unnecessary heat loss.

- Clinker tiles. It allows you to imitate brickwork, ceramics, natural stone, can have a shiny glazed or matte surface. The clinker is made from natural materials, but it significantly loads the facade structure. This finish is relevant for brick, monolithic concrete buildings, block walls. Installation is carried out on mortars, it requires a certain experience of masonry work from the contractor.

Each owner can decorate the pediment of a house or other object in an original and inexpensive way. It is only important to take a balanced approach to the selection of material, to accurately calculate the expected and permissible loads.

What do you need to work?

For work on sheathing the pediment, a number of materials and components will be required, which you definitely cannot do without. First of all, you will need to purchase the required number of selected trim elements, add-ons, ebbs and other components. It will also be useful polyurethane foam, with which the gaps will be eliminated. The frame part of the pediment is usually constructed using metal profiles or battens - the section of support elements and horizontal lintels is selected taking into account the load on this part of the facade.

Also, to carry out the work, you will need the following set of materials and tools:

- vapor barrier membrane;

- waterproofing film;

- construction stapler with staples;

- screwdriver;

- self-tapping screws;

- scissors or knife for cutting;

- fastening profiles (for siding);

- hacksaw for metal.

This is a basic list of the necessary fixtures. In addition, a long ladder or scaffolding will be required to carry out the work. For belaying at height, it is recommended to use a special rope and harness or belt.

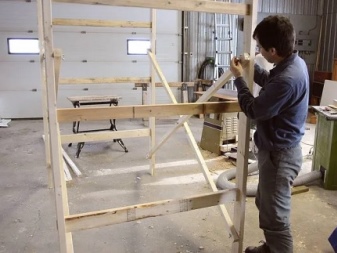

How to make scaffolding?

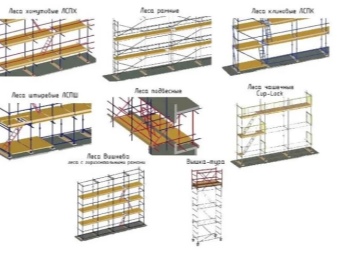

A small pediment can be sheathed with a wooden or metal sectional staircase. But if you have to carry out the installation of external finishes on a large scale, you cannot do without additional devices. Scaffolding provides comfortable movement along the pediment, making it possible for 2-3 people to work at once. It is not necessary to buy ready-made structures. Simple forests can be easily built with your own hands, taking into account the following requirements:

- flooring width - from 1.5 m;

- the height of the tiers - at least 1.8 m with a total of up to 6 m;

- distance between supports - up to 2.5 m;

- the maximum gap between the boards is 10 mm;

- beveled ends of elements (with continuous laying).

A primitive structure can be easily assembled from unedged boards and beams of sufficient thickness. Wooden structures have no more than 2 tiers and are not reusable.Metal scaffolding is assembled from a round or square shaped pipe. The horizontal flooring is made of wood.

The thickness of the boards is chosen by placing them on supports at a selected distance on the ground. The support should easily withstand several jumps on its surface.

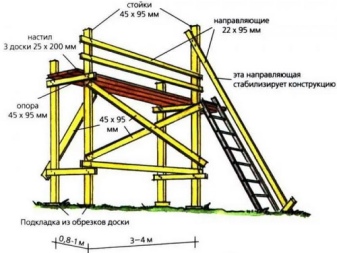

Installation of scaffolding made of wood is carried out as follows.

- Assembling the frame. It is formed from a bar with a section of 100 × 100 or 50 × 100 mm. The top of the supports is attached at a shorter distance from each other than the bottom. This will provide the structure with greater stability.

- Fastening of decking rails. They are mounted on the inside or outside of the frame.

- Joining of workpieces. At first they come in pairs. Then they are fastened with transverse bars and bevels. The more there are, the higher the bearing capacity of the forests will be.

- Installation of flooring. The lower tier is located no higher than 0.5 m from the ground. The second one is 1.8-2 meters away.

- Ladder formation... It is done by stuffing the transverse strips on the side of the scaffold frame.

The finished product can be equipped with rollers for greater mobility. In stationary use, the ends of the supports are slightly sharpened.

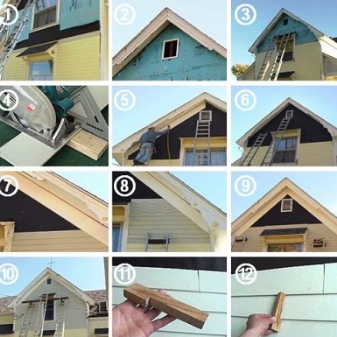

Plating technology

You can sew up the pediment with your own hands quickly enough. First, you need to make a preliminary calculation of the amount of materials, purchase everything you need. Then you can start directly finishing. The general procedure for facing the pediment will be as follows.

- Preparation. At this stage, the scaffolding is mounted up to the roof, the roof itself is inspected, if there are gaps, they must be repaired. Wood materials intended for installation are treated with an antiseptic.

- Installation of waterproofing. It will protect the under-roof space from moisture during work. It is attached to the lathing of the attic or attic, with an overlap, without gaps.

- Frame formation. You can build up the crate already used in the construction of a building or structure. If the wall is solid, and not frame, you will have to hem the suspensions. They are needed if a building is to be finished with brick or natural stone, with an uneven surface of the supporting structures. The direction of the bearing profiles is selected based on the type of finishing materials, in increments of 0.5-0.6 m.

- Decoration of window openings. They are sheathed with a profile, followed by the installation of steel sills.

- Fixing the sheathing. It is mounted from the bottom to the top corner. When working with siding and similar materials, after the first plank, roof extensions, edging and ebb tide are immediately installed. Then the rest of the elements are mounted, while maintaining a 1-2 mm gap to compensate for temperature differences.

This method is relevant for working with siding, clapboard, planking and other materials that are fixed in length, in a horizontal plane. The fixing of sheet coverings has some differences. In this case, the lathing is made more massive, from unedged boards 10-15 cm wide. Fastening is carried out vertically, so that the relief of the sheets is directed upwards. A cut of the edge in the corners of pitched roofs is performed after fitting, with manual marking.

Then the procedure will be as follows.

- Installation of 1 sheet. It is attached in the center of the pediment, with special screws to the crate.

- Installation of the remaining cladding elements. They overlap, in 1 wave.

- Low tide formation. It is made up of short pieces of the same material as the main skin.

- Installation of the upper corner. A specially cut part is installed here, repeating the corners of the roof slopes.

It is worth considering that the ondulin fastening in this case is performed in a wave, in pairs, with a pass through 4 protrusions. The profiled sheet is fixed in a recess, at the lower point of the corrugation.

Beautiful examples

Complex and beautiful options for finishing gables are no less popular than simple, basic ones. Often they try to make this detail of the facade as identical as possible to the rest of the design. But there are also design solutions that can become a real decoration of the building. The most interesting examples deserve special attention.

- Elegant cladding of the pediment imitating a stone with original paired decorative ornaments made of wood. The overall solution looks stylish and respectable.

- The intricate pediment of the house with brick trim. It is designed in the same style as the main building.

- Stylish cladding of the pediment with siding. The combination of materials with different textures in the decoration of this part of the facade looks interesting, gives the house a more respectable look.

In the next video, you will be decorating the gable of the house with a block house.

The comment was sent successfully.