How to make a boat out of plywood?

Specialist shops now offer a wide range of flotation devices. Choosing the right boat is not a problem, it's another matter that the cost of such a purchase is very high and not every fisherman can afford it. The way out of this situation is the independent manufacture of a floating craft, taking into account all personal needs. In this article, we will look at how you can make a boat from such an affordable material as plywood.

Peculiarities

A simple example of a homemade boat would be a punt. For greater convenience, it can even be folded. A collapsible boat is easier to move to the reservoir. This mini-option is also beneficial because the manufacturing costs are very low. Homemade plywood boats can also be motor boats and regular oars. In this case, the stern part will differ during manufacture. A transom will need to be installed under the motor (multi-layer plywood is suitable for it).

There are already developed popular models of boats, for example, the rowing sectional boat "Dori", "Okun" and many others, the drawings of which can be easily found on the Internet. And also in a specialized store you can buy ready-made kits for assembling a boat from plywood, for example, "Skif".

The price of such a set will be significantly lower than the cost of the finished vessel.

Materials and tools

To complete the work, we need the following materials:

- waterproof plywood 2.5 by 1.25 meters, its thickness should be 0.5 cm;

- 1.5 panels of moisture resistant plywood of the same size, but with a thickness of 0.6 cm;

- planed boards - it is better to give preference to soft and porous types of wood;

- wooden slats;

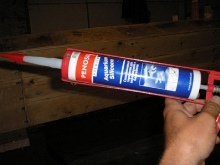

- epoxy resin;

- waterproof varnish or paint;

- nylon thread;

- fiberglass in a roll to paste over the hull of the boat;

- millimeter and thicker paper (cardboard can be used) for sketching;

- bars 0.5 by 3.4 m and 0.4x0.2x4 m.

And also prepare the tools:

- a screwdriver or drill with the required power;

- hand sander or planer;

- a clamp, or rather a few - if there is no special tool, then you can use clamps from old manual meat grinders;

- electric jigsaw;

- brass nails of various lengths and wood screws;

- hammer;

- roulette;

- brushes or roller for applying varnish.

How to build?

Let us consider in detail the entire technology of making a plywood boat with our own hands.

Preparation

Before starting work, you need to understand all the features of the future design: the shape and appearance of the vessel. When making homemade products, you need to take into account that the keel will be the basis of the vessel, the rest of the boat is attached to it. The nasal part is formed from the stem, it must be fixed on both sides. The stern is attached with a stern post. Both of these structures are responsible for the longitudinal stiffness of the vessel. They can be made from solid wood or from separate components, which will be fixed with hardware.

The transverse hull elements help to add rigidity to the boat. On top of the stem and sternpost, boards are placed, connected by the transverse edge of the body. In general, this whole structure forms the sides. It is also possible to install a cockpit, deck and side stringers.

To ensure good buoyancy, the niches are filled with foam, this helps to prevent the boat from capsizing.

Blueprints

Before drawing up a drawing of the boat, you also need to decide on its dimensions. This largely depends on how many people the ship should accommodate in the future. For the construction of a swimming facility from plywood of the specified thickness (0.5 cm), the following parameters will be optimal: length - 4.5 m, width of the largest part of the vessel - 1.05 m, depth of the floating craft - about 0.4 m. To create a project, it is better to use graph paper, this will make it possible to make more accurate contours of the elements of the ship's hull.

Next, we create a sketch:

- we draw an axial line along the length in order to divide the drawing into two parts, it is very important to observe symmetry in this case;

- further, we conventionally divide the diametrical plane into 4 sections, in which the transverse ribs of the body (frames) will be located in the future;

- we draw a projection of the vessel vertically, and also draw a view of the vessel from above;

- draw frames;

- be sure to check the parameters of all elements at a given scale;

- draw up sketches of frames on a 1 to 1 scale on thick paper;

- using a template and a long ruler, draw an image of curved lines;

- we check the symmetry of the drawing, for this you can fold it in half and compare the identity of both halves on the pattern.

Cut open

First, we transfer the entire image to thick paper. Then, using these templates, we draw details on plywood panels. It is necessary to adhere exactly to the contours and the selected dimensions. It is important to note here that there is no need to make allowances for allowances! After the transfer, we check the accuracy of all elements again. Since the plywood sheets can be smaller than the parts of the boat before cutting, several sheets are joined together. It is imperative that the joints are processed with a plane, then they are polished. The joints are pressed against the load.

With an electric jigsaw with fine teeth, we carefully cut the parts. The use of a special tool for this work ensures that there are no chips at the edges of the cut lines. After the cut, everything was done needs to be sanded. Then we make holes through which we will sew the hull of the ship.

They need to be drilled at an equal distance of 1 m so that the appearance of the product does not lose its aesthetics in the future.

Assembly

- Making a transom. This is the part of the boat hull to which the outboard motor is attached. To make this part, we glue several sheets of plywood to make a board with a thickness of about 25 mm. If necessary, this part can be strengthened with a wooden block.

- We drill holes along the edge of the stern and along the transom.

- On one side of the keel we install a stern post with a transom.

- We attach the stem to the other side.

- We connect the keel part with the pins with nails. Here it is important to check the complete absence of distortions. If necessary, adjust with a string between the transom and stem.

- We carry out the bonding.

- After installing the stem, we put the frames at a right angle. We check the fit with twine and carry out the final paperclip of the parts.

- For the task of deflecting the vessel without skewing, we use round bars. They need to be attached to the outermost parts of the keel from the inside. We also carry out fastening with uneven bars.

- Next, you need to sew the seams with nylon thread along the holes made. This material is highly durable and resistant to decay. The thread is impregnated with epoxy to give it extra strength.

- Installing the transom.

- Cut out the board elements from a pair of equal parts. Along the edges of the sides and the ledge of the bottom part, we drill holes every 1.5 meters. We assemble and attach the bottom of the vessel to the boat frame turned upside down.

- Then we sheathe the frame of the ship. We twist the elements. The sides on the bottom are fastened so that their ends are wound on the outside. In the future, the transom will be placed between them. It should be taken into account that the fibers of the skin material should be placed not across, but along the vessel.

- The joints of all parts and seams must be glued with several layers of fiberglass and greased with epoxy.In this case, each layer of fabric must be shifted to the side.

- To increase the degree of rigidity, you can strengthen the bottom with strips. To do this, we make holes on them for screws every 25 cm, put them in their places and fix them. Next, you need to make notes with a marker and remove them. We process the basting with an adhesive base and fasten them. After the adhesive has dried, take out the screws and hammer the structure with nails.

- We putty the holes of the casing with epoxy resin.

- We put the seat-banks.

- Outside, we process the boat with fiberglass glue. If this is not done, the subsequent coating (varnish or paint) will not last long. Plywood, like any wood material, has the property of shrinking and expanding under the influence of external factors. This will be especially noticeable on the bends of the vessel - the paint will begin to crack. We distribute the fiberglass over the surface of the sheathing, trying to avoid the appearance of folds and bubbles. It is better to glue the fabric, starting with the keel of the boat and moving towards each of the sides.

Painting

This stage will be the final one in our work. The inside of the surface must be painted with heated linseed oil. Outside, we apply paint to the fiberglass. It is better to use epoxy compounds, for example EP-140. We also decide on the color. If the vessel is multi-colored, we select the compositions of the required colors. You can apply a drawing or inscription on the surface, write the number or name of the boat. For this, it is permissible to use a self-adhesive film, this will add neatness to the ornament.

To apply paint, you can use a spray or roller, brush. The paint should be applied evenly: with a layer of the same thickness, strokes directed in one direction. There should be no smudges or gaps.

If done correctly, the coating will last for many years without cracking or chipping on the surface.

Testing

First of all, the boat must be checked directly at the place of manufacture. For this procedure, the boat is placed upside down on a bench or on several stools. Then, for 10 minutes, water is poured onto it from a hose. The longer the time of such a test, the more reliable the result will be. The vessel is then turned over and inspected for possible water leaks. If the boat has successfully passed such a test, then the next step will be to check it directly in the reservoir. To begin with, this is done in shallow water, the depth should be shallow.

If after lowering the boat into the pond there are no leaks for at least 40 minutes, you can complicate the task. At greater depths, pay attention to the speed of the boat and withstand various loads. Motors with low power (up to 5 horsepower) will withstand increased loads much worse than more powerful ones. The length of the boat will play an important role here: the longer it is, the better. On average, such a vessel should withstand approximately 150 kg of load. Be sure to launch the boat on a speedboat, check its course and position relative to the water surface.

Possible mistakes

It is worth paying attention to the fact that when building a vessel, fishermen often follow the standard recommendations, regardless of their weight. If it exceeds 90 kg, it is imperative to do additional reinforcement of the bottom with the help of slats, otherwise, when walking, it will be pushed down, and the water will push it up.

There are a few more tips to help you avoid common mistakes when making a boat.

- The use of nails during construction makes the process easier and cheaper, but the use of screws keeps the boat looking neater. In this case, the screws must be lubricated with any oil. Otherwise, in the future there will be difficulties with unscrewing the hardware.

- When fastening the rails, it is imperative to use clamps for fixing, otherwise it is very difficult to hold them.

- To avoid the appearance of "bubbles" on the vessel, the installation of hardware should be carried out at a short distance or in a row.

- To relieve the vessel from curvature during the installation of the rails will help to alternately hammering nails on different sides.

- Many people save epoxy when applied to bonding surfaces. In no case should this be done! The resin will simply be absorbed into the wood, and no sticking occurs. It is important to adhere to the consumption of epoxy in the amount of 200 grams per 3 meter strip of fabric. When the parts are compressed, resin residues should seep out - this is an indicator that the amount of epoxy is sufficient.

- Imperfections on the surface of the case can be removed with a waterproof filler.

- If the boat raises the bow and does not go to the glider, the centering is incorrect or the length is insufficient.

If the ship behaves well with two passengers, and begins to dolphin with one, this problem can be solved as follows: it is worth making a pair of hydrofoils from pieces of vinyl plastic and attaching them to the anti-cavitation plate of the motor. The boat will pick up speed faster, its progress will be easier. Thus, it is not difficult to make a fishing boat with your own hands, but it is still better for novice shipbuilders to choose a simpler design.

It is also not worth saving too much on materials - the durability of a home-made boat directly depends on their quality.

For information on how to make a boat out of plywood with your own hands, see the next video.

The comment was sent successfully.