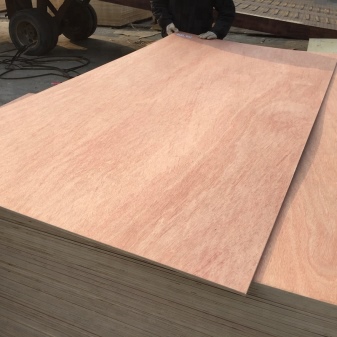

All about the weight of plywood

When buying any building or finishing material, you need to be aware of its strengths and weaknesses, functional and technical characteristics. All other qualities will depend on the thickness and weight of plywood. More complete information can be obtained by reading about the manufacturing plant, the raw materials used for production, the parameters of a particular brand.

Influencing factors

Plywood is a multi-layer material of veneer sheets connected in a crosswise direction of the grain. Veneer is thin layers of wood, no more than 4 millimeters. In the manufacture of plywood, veneer from different types of wood is used, the only difference is in the method of production. Its mass and characteristics may vary, it all depends on the specific gravity, texture, moisture and moisture resistance. The factors affecting weight the most are the thickness and area of the material, as well as the type of wood.

For gluing veneers together, formaldehyde resin is used. In turn, depending on the additives, plywood is divided into several types.

- FBA is an environmentally friendly product, it contains natural glue. Low moisture resistance.

- FB - bakelite. Not afraid of moisture, used in shipbuilding. Each layer is glued together with phenolic resins and impregnated with bakelite varnish.

- FC - the composition includes urea. It has low moisture resistance, it is used only for interior decoration.

- FSF - with the addition of phenol. Durable product with increased moisture resistance. It can be used for both interior and exterior decoration.

- FOF - laminated type of product. The characteristics are the same as for FSF, the difference is that it has a lining made of a special film.

- BS or aviation - the material of the highest quality, veneer for production is taken only the best grades. Sufficiently voluminous, alcohol-soluble glue is used for production.

- BV is not as moisture resistant as BS. The veneer is glued together with a water-soluble compound.

It should be remembered that the density will not depend on the type of glue. But it can change from the amount of resins. 1 m3 of resin has a weight of about 800 - 850 kilograms. Therefore, the more adhesive is used, the higher the density of the finished plywood. Manufacturers for the sake of harmlessness and environmental friendliness can reduce the amount of glue.

All characteristics of plywood are related to each other, and much depends on the thickness. For example, we can consider FC plywood 10 millimeters thick - this is the most popular and demanded type. A product of this thickness has 7 layers of veneer, a pack with a volume of 1 cube will consist of 43 sheets, but by the standards of sheets in a package it will be 3 pieces less. Therefore, it will amount to not 1, but 0.93.

It is imperative to take into account the permissible errors in thickness, it depends on whether the material is sanded or not.

Sheets of 2-8 millimeters are used in the manufacture of furniture, 8-12 millimeters - as surface finishing. Plywood can be manufactured in standard sizes corresponding to GOST - 1.525 square meters, 1.22x2.44, 1.25x2.5, 1.5x3, 1.525x3.05 meters. And also on request - other parameters required by the customer.

Mass of plywood from different materials

To determine a more accurate weight of plywood, there are special tables, all the necessary parameters and calculations have already been entered into them. Here is the density of veneer made from such materials.

- Birch trees - 650 kg / m3.

- Larch, pine or spruce - 550 kg / m3.

- Poplars - 500 kg / m3.

- Cottonwood or seiba - 350 kg / m3.

- Bakelite plywood can be distinguished separately, its density is 1200 kg / m3.

Birch plywood has the highest density, so its strength values are the best.

Such material has increased resistance to stress and moisture. The color should be yellow-white, sometimes pink, with a well-visible texture. Even if two sheets of plywood have the same area and thickness, but are made of different types of wood, different glue was used, the pressing and drying technology was different - the weight will not be the same.

You can calculate the weight of the product yourself, knowing the formula - "density x volume = mass". For example, you need to find out how much 105 sheets of coniferous plywood weigh, 1500x3000 millimeters in size and 8 millimeters thick. We must not forget to translate all parameters into one unit of measurement, in this case in meters. Now you need to substitute the data into the formula:

1.5x3x0.008x550x105 = 2079 kilograms.

How much do thin and thick sheets weigh?

Thickness of thin sheets varies from 0.4 to 6.5 millimeters. This includes aviation plywood and brands FC, FSF. Describing the average density for plywood from different types of wood, the following can be distinguished.

- Sheets with dimensions 2.44x1.2 meters, 6.5 millimeters thick from birch - 12.6 kilograms, and from conifers - 10.6 kilograms.

- Plywood with the same dimensions but 12 millimeters thick from birch veneer - 23.2 kilograms, from coniferous - 19.6 kilograms.

A similar difference in weight will be for materials with a square shape, with a thickness of 6.5 millimeters.

- Birch - 9.07 kilograms.

- Coniferous - 10 kilograms.

Plywood of medium thickness includes sheets - 8, 9, 10, 12 and 15 millimeters. Such materials are popular in construction, furniture manufacturing, mechanical engineering, and roofing. By the type of surface, it can be divided into polished and unpolished. The highest grades should be with a beautiful, aesthetic texture and appearance.

Plywood of this thickness is mainly produced by the FK and FSF grades.

As an example, consider a veneer with a thickness of 12 millimeters, with parameters 1.22x2.44 meters.

- Birch - 23.2 kilograms.

- Needles - 20.6 kilograms.

Thick plywood includes sheets with parameters - 18, 20, 21, 24, 30 millimeters. Its main feature is strength, therefore the material is very often used as a load-bearing element in the manufacture of furniture, construction, etc. Separately, one can single out material with a thickness of more than 40 millimeters, it is mainly made to order, since it has a very narrow specialization.

The veneer with increased thickness is produced in three types - FC, FSF, FOF. The most popular are 18 and 21 mm. For example: birch veneer 1.525x1.525 meters with a thickness of 18 will weigh 35.8 kilograms.

How much plywood weighs, you need to know for delivery to the place of work. There are many ready-made tables with both softwood and birch veneer weights. You can also use an online calculator, just enter all the parameters and click the "calculate" button.

For the types of plywood, see the video.

The comment was sent successfully.