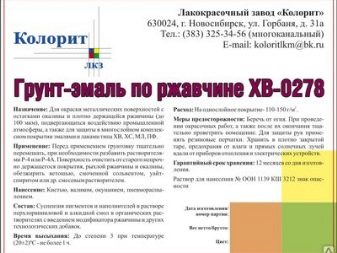

Primer-enamel XB-0278: characteristics and rules of application

Primer-enamel XB-0278 is a unique anti-corrosion material and is intended for processing steel and cast iron surfaces. The composition protects metal surfaces from the appearance of rust, and slows down the process of destruction of structures already damaged by corrosion. The material is produced by the company "Antikor-LKM" and has been present on the domestic construction market for 15 years.

Peculiarities

Primer XB-0278 is a type of composition in which a primer, enamel and a rust converter are combined. The composition of the coating includes polymerization polycondensation resin, organic solvents and modifying additives. This allows you not to resort to the use of different compositions, which significantly saves budgetary funds and reduces labor costs.

The primer copes well with rusty foci and scale and is able to neutralize corrosion that has reached a value of 70 microns.

Treated surfaces are resistant to harsh environmental influences, salts, chemicals and reagents. The only limiting condition for the operation of the composition is the ambient air temperature exceeding 60 degrees. The composition, applied in 3 layers, is able to maintain its performance characteristics for four years. The product has good frost-resistant qualities, therefore it can be used for processing metal structures in conditions of negative temperatures.

Scope of use

Primer-enamel XB-0278 is used for anti-corrosion and preventive treatment of all types of metal structures. The composition is used to paint machines and units that are exposed to gas, steam, negative temperatures and chemical reagents and which have a zone of carbon deposits, rust and scale not exceeding 100 microns.

The primer is used to cover gratings, garage doors, fences, fences, stairs and any other metal structureshaving large dimensions and complex profile. With the help of XB-0278, a basis is created for the further application of any refractory coatings.

The material is fully compatible with paints and varnishes of the type GF, XV, AK, PF, MA and others, and can be used both as an independent coating and as one of the layers in combination with weather-resistant enamel or varnish.

The composition is used in cases where mechanical cleaning of metal from rusty deposits and scale is impossible or difficult. When carrying out car body repairs, the mixture can be used to treat the inner surface of the wings and other body parts that do not require decorative coating.

Specifications

Primer mixture XB-0278 is manufactured in strict accordance with GOST, and its composition and technical parameters are approved by certificates of conformity. Indicators of the relative viscosity of the material have an index B3 246, the time for complete drying of the composition at a temperature of 20 degrees is one hour. The amount of non-volatile components does not exceed 35% in colored solutions and 31% in black mixtures. The average consumption of primer-enamel is 150 grams per square meter and may vary depending on the type of metal, the size of the damaged area and the thickness of corrosion.

The elasticity of the applied layer when it is bent corresponds to an indicator of 1 mm, the adhesive value is two points, and the hardness level is 0.15 units.The treated surface is resistant to 3% sodium chlorine for 72 hours, and the rust conversion coefficient is 0.7.

The primer mixture consists of epoxy and alkyd resins, plasticizers, corrosion inhibitor, rust converter, perchlorovinyl resin and color pigments. Hiding power of the solution ranges from 60 to 120 grams per square and depends on the presence of color pigment, coloring conditions and the degree of damage to the metal.

The cost of the primer enamel is approximately 120 rubles per liter. The service life of the protective film is four to five years. It is recommended to store the material at temperatures from -25 to 30 degrees, the packaging should be protected from exposure to direct ultraviolet rays, the jar should be tightly closed.

How to apply correctly?

The application of the primer mixture should be done with a roller, brush and pneumatic spray gun. Immersion of products in the solution is allowed. Before applying primer XB-0278, the surface of the metal structure must be carefully prepared. For this, it is necessary, if possible, to remove loose rusty formations, dust and degrease the metal.

For degreasing, use a solvent such as P-4 or P-4A. The same compounds should be used to dilute the enamel when using the pneumatic spray method. When applying the primer using other tools, it is not necessary to dilute the composition. The air temperature during processing should be in the range from -10 to 30 degrees, and the humidity should not be higher than 80%.

If the primer mixture is used as an independent coating, then priming is done in three layers, the first of which should be dried for at least two hours, and an hour is enough to dry each of the subsequent ones.

The first layer serves as a rust converter, the second serves as anti-corrosion protection, and the third is decorative.

If a two-component coating is formed, the surface is treated with a primer mixture twice. In both cases, the thickness of the 1st layer should be at least 10-15 microns, and each of the subsequent layers should be from 28 to 32 microns. The total thickness of the protective film, with strict adherence to the installation technology, is from 70 to 80 microns.

Useful Tips

For maximum protection of the metal surface from the damaging effects of corrosion, it is necessary to strictly follow the installation rules and adhere to some important recommendations:

- the application of only one layer of the material is unacceptable: the mixture will be absorbed into the loose structure of rust and will not be able to form the necessary protective film, as a result of which the metal will continue to collapse;

- the use of white spirit and solvents that are not indicated in the instructions for use is not recommended: this can lead to a violation of the operational properties of the enamel and significantly increase the drying time of the composition;

- it is forbidden to use the painted surface until it is completely dry: this can disrupt the polymerization process, which ultimately will negatively affect the quality of the protective film;

- you should not use primer enamel when processing smooth surfaces: the mixture was created specifically for working with rusty rough materials and does not have good adhesion to smooth ones;

- the soil is flammable, therefore, processing near sources of open flame, as well as without personal protective equipment, is unacceptable.

Reviews

The primer mixture XB-0278 is a demanded anti-corrosion material and has many positive reviews. Consumers note the ease of use and high speed of installation.

Attention is drawn to the availability and low cost of the material. The protective properties of the composition are also highly appreciated: buyers note a significant extension of the service life of structures damaged by rust and the possibility of using soil for processing car body parts.The disadvantages include an insufficiently wide color palette of the composition and a long drying time for the first layer.

For interesting information on metal corrosion, see the following video.

The comment was sent successfully.