Where is aerosol and other types of enamel used?

Starting from the 90s of the last century, when renovating apartments in Russia, they increasingly began to prefer enamel to ordinary paint. In this regard, numerous questions arise about the difference between enamel and paint, about the scope of its application, and most importantly, what kind of enamel to choose to restore a bath or a roof in the country?

What it is?

So, enamel is a special coating based on a suspension of pigments, which include fillers such as varnish. After drying, the enamel forms a glassy film on the surface of the things painted with it, which is much stronger than ordinary thin glass. It is usually covered with products made of materials such as bronze, steel, cast iron, copper, sometimes even silver and gold.

The advantages and disadvantages of enamel are immediately visible - it protects products from corrosion and even stops this process. This coating lasts longer than conventional paint - on average, 5-10 years. Another plus of enamel is its low coefficient of expansion, several times lower than that of metal. Due to this, excellent adhesion to the base, that is, the same metal, occurs, and the wear resistance and service life of such a coating is increased.

An equally important characteristic of enamel is the value of the modulus of longitudinal elasticity, which also increases the adhesion strength of the coating to the material. When it comes to applying to precious metals, then this feature helps the enamel to acquire a shine and brightness of color, which does not fade for decades.

The main disadvantage of enamel is its rather high toxicity and a pungent odor, which then does not disappear for a long time.

If you have to work with certain types of enamel, for example, alkyd, indoors, then it must be thoroughly ventilated, preferably 1-2 days. It is necessary to work with enamel in protective clothing and a mask, and preferably in a respirator. If there are small children in the house, it is better to move them to another room for a couple of days. To solve this problem, stores began to sell weak solutions of enamel for household use - their smell is not so pungent, but they also serve less.

Any product officially supplied for public consumption must comply with GOST or an interstate standard, that is, have a set of optimal technical characteristics and meet the correct percentage of constituent components. Enamels are not an exception, especially since they are considered quite hazardous substances for domestic use.

Before you buy one or another jar of enamel, read on the packaging which GOST it corresponds to and whether it matches at all. Each digital marking contains specific instructions on the composition and scope of the enamel coating. The decoding of the standard can be obtained by contacting the seller - consultant.

Peculiarities

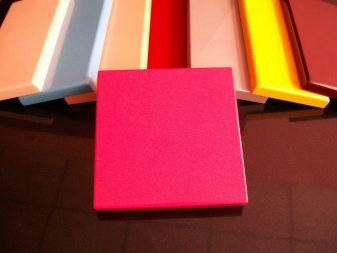

The main feature of enamel in comparison with conventional paint is the film that covers the metal surface after its application. The film can be both glossy and matte - it all depends on the elements contained in the coating. The color range of enamel is also very diverse - it is not always white, as we are used to seeing it on the surface of the bathroom or washbasin. Black and even multi-colored enamels are not uncommon now.

In any shade, you can be sure that a high-quality coating will retain color brightness for years, will not fade or yellow.

The best ratio of characteristics is possessed by alkyd enamelsconsisting of synthesized alkyd varnishes and organic solvents. Special additives provide an antiseptic effect and resist the development of various fungi and mold. Such enamel is good not only for the bathroom and the outer walls of pipelines, but also for any rooms and objects with a humid environment.

Most enamels also contain anti-corrosion additives, which is especially important for metal surfaces in the open air, exposed to temperature extremes and exposure to water.

Some types of enamel have a high cure rate when cold dried. So, coatings for interior premises will freeze for 6 - 12 hours, and pentaphthalic enamels are suitable for outdoor objects. Due to their chemical composition, they set in 3 - 4 hours, so that all work can be completed before the onset of rain.

Possessing high elasticity, enamels fit well even on the most uncomfortable surfaces and uneven joints, covering everything with an even layer of glassy film. Also, during the restoration of the bath, the enamel, being elastic, stretches well with a viscous mixture along the entire perimeter, leaving no irregularities with high-quality application.

This type of coating also does not shrink, which is its main difference from other paint and varnish compositions.

The compositions of most types of enamel are also distinguished by a high degree of strength and opacity, although it all depends on the method of application - whether it be an ordinary brush, roller or spray gun. Of course, when applied in one layer, the enamel will be less dense than with multi-layer work, but in any case, the original surface will not be visible, as when applying one layer of ordinary paint.

Views

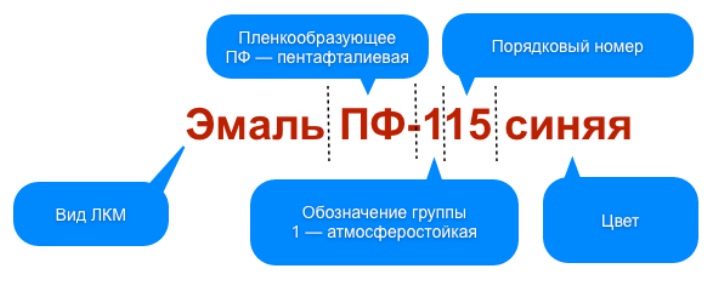

Nowadays, on the shelves of hardware stores, you can find a huge number of different types of enamel. The main thing here is not to get confused by correctly interpreting the GOST marking. To begin with, it is worth understanding the basic classification of enamel, depending on the main chemical component of the coating.

Nitrocellulose enamels, made, as the name implies, on the basis of cellulose nitro components. Such a composition that is scary by ear should not scare you before purchasing, since this enamel is completely harmless and is widely used in everyday life.

In particular, they like to buy it for painting metal fences, water and battery pipes, as well as for working with concrete and wood objects.

Among the minuses is the pungent smell of acetone, which, however, disappears almost without a trace in a day. Another important detail is incompatibility with other types of paints, that is, it is better to update individual parts of the structure with the same type of coating. As an advantage, there is a different packaging - both in cans and in cans, depending on what purposes the enamel is used for.

Silicon enamel It is widely used in bathrooms and other rooms with a high level of humidity, since it is silicon that has the ability to draw out excess moisture and prevent the formation of fungi. Also among the advantages are the strength and wear resistance of the film formed by it. Not to say that this type of enamel has good compatibility with other paints, but at least it takes after itself acrylic mixtures.

Urethane and alkyd-urethane enamels are distinguished by good strength and wear resistance due to the gentle chemical elements in the composition. They also allow you to apply such a coating to a surface that was previously painted with pentaphthalic and epoxy enamel, as well as ordinary oil paint.

Its convenience is that the urethane version fits well, even if the object has not been cleaned to the ground from previous layers of the above types of paint.

Most popular in household use - acrylic enamelswater-based.This is the safest and most non-toxic composition of all the types of enamels listed above, so even children use ordinary acrylic paints.

Despite the weak water base, acrylic adheres well to almost any surface - not only on metal, but even on glazed porcelain that is smooth and inconvenient for paint application. At the same time, water resistance as the main characteristic does not disappear anywhere. Acrylic is well compatible only with other types of paintwork materials on the same water basis.

In the classification of enamel types, a huge number of both letter and digital markings are used. Each type has its own scope of use, shelf life and technical characteristics. Next, consider the most popular names for paint and varnish enamel.

AC-554 enamel based on acrylic and alkyd is also called tractor, since it is often used for painting tractors and automobiles operating outdoors in conditions of constant variability of weather conditions. This type of enamel consists of a pigment suspension with the addition of various stabilizers that can maintain a rich color for a long time.

The shade of this coating is predominantly bright orange and red, so objects that need to be drawn to a person's attention are painted with it. In addition to working equipment, which should be clearly visible from a long distance and in the dark, road signs and signs, buoys and even aircraft parts are covered with AC-554 enamel, because the coating tolerates both extreme cold and heat well.

The obvious advantages of this enamel are good corrosion resistance, weather resistance and high adhesion, that is, the ability to firmly adhere to any surface. AC-554 dries very quickly - one layer does not exceed an hour, but, unfortunately, it is not enough for high-quality painting. The ideal option is to apply three layers, but then the enamel will dry out for at least a day.

Compatibility with other types of paints is not very good, therefore, it is better to clean the surface before coating with this type of enamel with a special primer. If the object to be applied is smooth, then the enamel will lay down without noticeable defects and irregularities, having a high percentage of viscosity.

Conveniently, AC-554 does not lose its appearance with constant contact with gasoline, therefore it is used when painting equipment with a gasoline engine. It is ideal to apply such enamel in combination with varnish AC-528 and primer AC-071, so that the rich color delights the eye for a long time and does not fade in the sun. If such a bright shade is not needed, then to obtain a calmer gradation, the enamel can be diluted with xylene.

Although the mass of non-volatile, that is, toxic substances in the AC-554 is relatively small, it is better to work with it with gloves and a mask. It is applied using a pneumatic spray gun, so be careful not to get this enamel in your eyes.

The shelf life of the AC-554 is short - only 6 months from the date of manufacture.

Be careful in the store and be sure to look at this marking - if at least 4 months have passed since this date, then you should not purchase such a product.

Enamels GF-92 and 1110 Is another popular product among Russian consumers due to its increased durability. In the industry, they are used to paint cars, so at home you can also try to fix small defects and chips on your car in the garage.

This type of coating is based on pigments with the addition of urea-formaldehyde resin, which allows it to withstand all atmospheric changes for many years. Separately sold enamel for application to the surface of electrical devices and cars, and another type - for covering the moving parts of the same devices. Both types, however, have a high degree of protective properties, and can also give a decorative appearance to the painted surface.

Color GF-92 it can be gray or brown when choosing a type with processing by means of cold drying.If hot drying seems more reliable for setting the material, then there is no need to choose - such enamel is of an exclusively gray shade. GF-92, like 1110, dries for a long time - about three days, taking into account the recommended application in three layers and drying of each of them within 24 hours.

If it is applied, observing all the rules, then the maximum protective properties of the enamel will appear for up to two years, and then for about five more years such a surface will be suitable for use.

This enamel is applied to a surface previously cleaned with a special primer. It should be borne in mind that first the soil must be allowed to dry for at least 2 hours, and only then the first layer of GF-92 should be applied. This type of coating tends to thicken quickly during use, so it can be thinned with pre-prepared toluene, solvent or white spirit. Enamel is also sprayed pneumatically in compliance with all safety rules when working with a flammable substance. The shelf life of GF-92 is twice as long as that of the above-described option - 12 months, so you can safely buy a jar that has been on the shelf after production for six months.

Enamels XB-16 and 518 can, perhaps, be called the most versatile options for painting almost any surface in everyday life. They are ideal for use on building facades, concrete structures and even wood and textile work. In terms of chemical composition, enamel is a mixture of various pigments found in solvents, so the color of the soil here can be completely different. The shelf life of the coating also depends on the color - for a silver shade - 6 months, for all others - a whole year.

Enamel ХВ-16 it is considered quick-drying, since it takes only an hour and a half to dry one layer. The main thing is that the temperature is not lower than 20C, so it is better to carry out painting work in the summer. You need to apply the enamel in two or three layers, then it will lay down smoothly, without defects and streaks. A high-quality coating will allow it to maintain its best qualities for a long time - resistance to contact with water, to various weather conditions, as well as to contact with oil paints and oils.

Application of XB-16 will require pneumatic or airless spraying with appropriate precautions. As usual, the more coats you apply, the longer the enamel will last - 2 coats within three years, and 3 coats for at least 6 years.

To make the coating better adhere to the surface and dry faster, you can dilute it with solvents such as R-5 or R-5A.

Enamel NTs-25 - a rather corrosive pigment-based suspension in combination with a nitrocellulose solution and the addition of resins with organic solvents. Despite this, in a low concentration, such coatings are sold in an odorless modification, which is very convenient for working in residential premises or in crowded places. That is why the main area of application of NTs-25 is primed metal surfaces, wooden products and even equipment used indoors.

To apply this enamel to the surface, it is necessary to carefully prepare, that is, to clean not just of old layers, but also from dust, dirt, grease, and then sand it with a sandpaper and walk with a degreasing solvent. And even after all these procedures, it is impossible to cover the surface that was previously exposed to oil paint.

From the convenience of working with NTs-25, there are various methods of application, that is, a brush, and filling, and an aerosol method. Most importantly, do not forget to thoroughly mix and dilute the enamel with a solvent marking 646 or 645 before starting work.

Enamel ML-12, as well as the line of coatings BT 177, XC 759, EP 51 and 182, is very popular due to the widest selection of bright and juicy ground shades - white, orange, golden, gray-blue, blue, black, green, red, smoky, marine color waves and many others.So many colors were obtained due to their composition in the form of a suspension of pigments in a solution of alkyd and melamine-formaldehyde resins in organic solvents.

Due to the possibility of obtaining almost any shade, ML-12 enamel, as the most frequently purchased of all of the above, is widely used in domestic automotive production, but craftsmen use it to correct defects in their cars at home.

They also take it for painting playgrounds and any other object where a bright saturated color is needed, both indoors and outdoors. ML-12 also gained such popularity due to its good ability to resist the influence of an aggressive external environment.

If you want the enamel to dry in 30-40 minutes, you need to continuously spray the surface with a burner with a temperature of at least 130C, the process will be practically odorless. When this is not possible, we just leave it to dry in the sun for 6-8 hours.

ML-12 is applied to a well-cleaned and sanded object in several layers.

Enamel HP-799, as well as 5116, NPF, 125 and 572, are extremely resistant to aggressive acidic or alkaline environments, therefore they are used for painting metal, reinforced concrete, certain types of cement and even wood, constantly interacting with such negative conditions. In addition, the enamel of this group is very resistant not only to chemicals, but also to the formation of cracks, and even when used under conditions of maximum temperature differences - from -60C to + 130C. Also, HP-799, which will be discussed further, is practically not subject to erasure, that is, it can be used in everyday life for the most problematic objects.

Such enamel dries out quickly enough - in about 7 hours, and between the application of each separate layer, the waiting time is 2-3 hours. The main condition for uniform spreading and good drying is to bring KhP-799 to the required level of fluid viscosity using xylene or toluene.

When applied to a metal surface, it must be treated before applying the enamel with a primer GF-021 that is ideally compatible with it.

You can use HP-799 enamel in almost any convenient way - airless, pneumatic, brush or roller. In any case, this coating is very economical and its consumption per 1 square meter of surface is approximately two times less than that of all the above options. The peculiarity of HP-799 is that it is better to mix it with special solvents before use and keep it for about a week for the desired degree of thickening.

The last line of enamels in the review is "Elakor PU" 60, 1236, 436, 710, 720, 161, as well as "Polyton-UR" or in some UV markings, used to resist corrosion of metal surfaces in conditions of increased moisture or even aggressive exposure to petroleum products. Thanks to the two-component paint and varnish composition of acrylurethane resins, this enamel can function successfully in almost all weather conditions. In addition, "Polyton-UR" and its brothers are resistant to high ultraviolet radiation and do not fade, giving the painted surface a pronounced decorative effect.

Such enamel can have almost any shade of soil, especially for large batches. It does not crack on impact, has excellent heat resistance, dries in about 7 hours and is economical to use. The mass fraction of toxic non-volatile substances in them, however, is quite large, therefore, enamel should be applied with a full protective set and a temperature of at least 20C.

Colors

Store shelves are flooded with enamels of completely unpredictable colors in the struggle for consumer choice. We are all familiar from childhood mainly with white enamel for the bathroom, but we should not be limited to this. One shade or another is obtained by mixing different coloring metals.

Blue enamel can be obtained by adding cobalt oxide or copper to the composition. She is often covered with pipes or even walls in outbuildings outside the city.

For a summer cottage fence or shutters, green enamel is often used, created from a mixture of chromium or copper oxides, as well as nickel.

Pink enamel is also popular now - it is used in the interiors of art spaces or beauty salons, for painting a girl's bicycle. This delicate shade is obtained from a mixture of chromium and tin oxides.

The most popular enamel color is black. It is often used in the interiors of living quarters, even for the same plumbing. This color is formed from a mixture of nickel oxides in a combination of iron and manganese, sometimes with the addition of cobalt and chromium compounds.

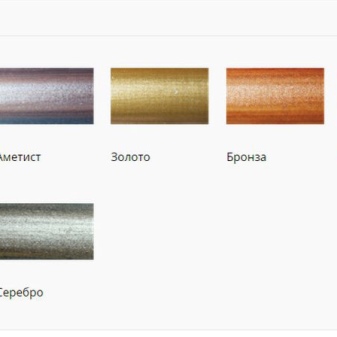

Pearlescent VGT - know-how of recent yearsdesigned to work with a variety of surfaces such as wood molding, plaster or metal. In addition to the already colored decorative plaster or clear colorless wallpaper, mother-of-pearl enamel can also be applied.

It contains such elements as pearlescent pigment, water-based dispersion acrylic polymer and modifying additives. Thanks to this, it was possible to obtain unusual shades such as gold, bronze, pearl, garnet, silvery white and even the color "chameleon".

The color scheme actually depends not only on the initial composition, but also on the color of the lining - the primer, the spray method and the number of layers applied.

Mother-of-pearl VGT enamel is used not so much to protect the surface from an aggressive environment, but to give an even greater decorative effect, characteristic shine and interesting texture to the element of the design decoration of the room. Nevertheless, such a coating is used both for application to objects that are permanently indoors and for objects that are outdoors for most of the year, having a high resistance to atmospheric changes and resistance to water and light.

If necessary, such enamel can be diluted with water as a solvent, but the proportion of water should not exceed 5%, otherwise the enamel will lose most of its protective properties.

Packaging

As for the packaging of various types of enamel, it is most often subdivided into small and large. The first option is between 0.5 kg and 3 kg. Some types of enamel, sold as a dry mix, which must then be diluted, are sold in packages of 10 kg, and this is also considered a small package. Large packaging is more suitable for industrial purposes and starts from 15-20 kg. Accordingly, if the enamel is supplied in the form of an already diluted liquid substance, then a volume of 0.5-3 liters is considered a small package. Containers larger than 10 liters, as in the previous version, refer to large packaging.

All types of enamel, regardless of the initial state of aggregation, are packed in a special container made of polyurethane plastic or special types of light metal, where the packaging materials comply with GOST. The lids of such containers are hermetically sealed with solders, so that after the first use it is no longer possible to talk about one hundred percent clogging. However, due to the volatility of toxic materials, some containers for enamel are equipped with special latches on the lid, so even after opening you can be sure that harmful vapors will not enter the apartment.

Selection and application

When choosing a certain type of enamel, it is better to first familiarize yourself with which brand is used for what purposes. In the store you can find a huge number of enamels for approximately the same types of surface, so it is better to know in advance so as not to overpay or buy a very persistent and caustic type of enamel where one could do without it.

According to GOST marking on containers, the following information can now be determined:

- what surfaces the enamel is used for;

- what is the rate of drying of the enamel, as well as the degree of its viscosity, elasticity and toxicity;

- what percentage of non-volatile harmful substances is in it;

- how many layers are necessary for the full functioning of the coating, as well as the way in which it can be painted with enamel;

- what kind of solvent or primer is used in conjunction with this type of coating;

- what similar paint and varnish coatings the enamel is compatible with;

- whether it should be diluted or mixed, and also how long after dilution is given to work until it thickens.

Enamel serves as a coating for the following objects: road signs, electrical equipment, cars, house facades, roofs, crockery and whole sets, interior details and, of course, the familiar bathroom restoration.

Enamel is also successfully used in jewelry and as a decoration for luxury interior items. For the needs of jewelers, they use cloisonné enamel, known since ancient times, which is difficult to manufacture and is not sold in ordinary hardware stores.

Tips & Tricks

The correct application of the enamel often determines how evenly it will lay on the surface and how long it will last.

Here are some tips from professionals in the field:

- For airless spraying, it is not recommended to dilute the enamel with a solvent, since without a certain degree of viscosity such a coating simply will not evenly come out through the sprayer under the required pressure. It is better to use a nozzle with the thinnest possible diameter, no more than 0.3 mm. The pressure, on the other hand, must be strong enough, about 150 bar.

- If the composition is sprayed by air, then such a universal solvent as solvent will come to the rescue. However, do not overdo it with the addition of this substance, do not add more than 5% of the total mass of the composition. Unlike the first option, it is better to take the nozzle here much thicker - about 2 mm, and, on the contrary, reduce the pressure to 4 bar.

- The easiest way to apply enamel is with a roller or brush. The only advice here is to also dilute the composition with a solvent no more than 5% of the total mass. To avoid throwing away leftover solvent, it can then be used to rinse all application tools for reuse.

Manufacturers and reviews

According to readers' reviews, the most popular brand for a good price / quality ratio is the manufacturer Tikkurila... These types of enamel are easy to apply, dry quickly, and after staining do not leave roughness and sagging on the surface.

Enamel stamps "Lacra" and "Tex" not so easy to apply, but they are considered more wear-resistant and less susceptible to destruction with constant exposure to moisture and temperature extremes. They are often used to paint pipes near batteries and water pipes.

Certa and Isolep mastic - far from the cheapest types of enamel, however, according to customer reviews, they are the most reliable. Due to the fact that these manufacturers have a rich tint supply of enamels in their arsenal, they are often used to update chips on cars at home. The effect, say avid car enthusiasts, is such that sometimes you cannot distinguish it from salon painting.

See below for a comparison of alkyd and acrylic enamel.

The comment was sent successfully.