Subtleties of connecting an induction hob

Induction hobs have become extremely popular in recent years. But it is not enough just to choose the right product, you also need to install and connect it correctly. Not knowing how to do this can lead to many mistakes.

Peculiarities

The reason for the popularity of inductive cookers is quite understandable: they are as comfortable as simple electric ones, but at the same time they are more economical. The practicality of such a device can hardly be questioned. However, connecting an induction hob has its own subtleties and nuances. Usually manufacturers indicate that it should only be carried out by trained electricians.

This requirement is described as a separate item in any warranty card.

The problem is that the cost of a specialist's services is quite high, and naturally there is a desire to connect an induction panel with your own hands. To do this, you will have to thoroughly study the topic and especially the key technical requirements. They concern:

- connection points;

- the type and section of the cables used;

- their total length.

Power and its meaning

Typical power for induction cookers is 7.2 kW. This is the highest current consumption. Of course, when 2 or 3 cooking zones are used daily, the consumption will be less. But electricity consumption is also determined by how quickly you need to warm up the oven.

When connecting a single-phase type induction surface, with free conversion, 7.2 kW must be divided by 230 V. It turns out an indicator of 31.3 Amperes. But much more often it is used three-phase network with two phases... Each of them can support a pair of heating fields of identical thermal power, therefore, in the circuit, the power of a particular phase is approximately 3.6 kW (corrected for efficiency). So, according to the same formula, an indicator of 15.7 Amperes is obtained.

Important: they are guided precisely by the limiting indicator. Any hob must be prepared for the case when it will work at the maximum mode. It is better to anticipate this development in advance than to suffer the consequences of miscalculation. Therefore, the scheme for connecting to the mains is thought out even before the acquisition of an induction device.

It is very bad when the power of the network is inferior to the power of household appliances.

Then either the main fuse will constantly "fly out", or the mains wires will overheat. In apartments built in the 1960s, the electrical network is simply not designed for connecting an induction hob. At that time, an electric power of 5.5 kW was allocated for one apartment, and this was considered an indicator that covered all imaginable needs. Obviously, the solution is to purchase less powerful kitchen equipment. Alternatively, you can buy and a model that allows you to reduce the level of current consumption.

When you can't bet

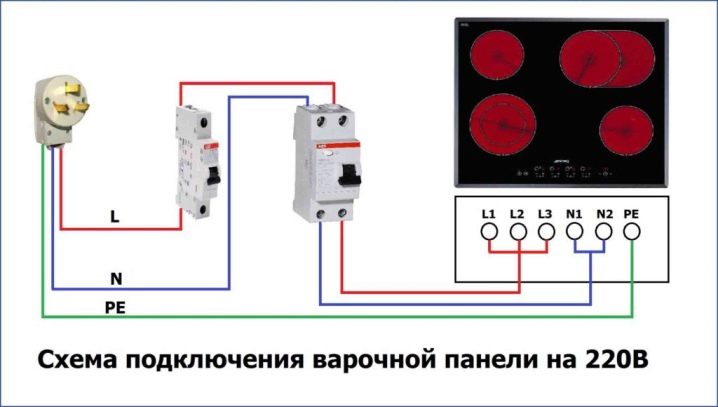

Important: both independently and with the help of professional electricians you cannot connect the inductive panel to a single-phase 220 V. The fact is that such systems are not designed for high power devices. We'll have to pull another cable between the distributor and the device. It is also very important to improve the characteristics of the switchboard.Otherwise, connecting an induction hob can be dangerous.

How to connect an induction hob yourself

If there is already a sufficiently powerful initially or modernized electrical network in the house, this greatly simplifies the matter. But still, you can't just insert the plug into a regular outlet and calm down on this. It is necessary to make sure that the network parameters in the apartment are not lower than those required by the instructions. And ideally, you should provide even better protection.

If the technical passport indicates that the protection should be designed for 30 A, then it is advisable to use protective network elements for 25 A. Having dealt with this point, you can also deal with the cable. When a standard connection to the outgoing cable is provided, conductors can be used:

- black or brown color (phase);

- yellow-green tone (protection);

- blue and gray (neutral).

Sometimes the cross-section of the wire is not suitable across. Power cords with a cross section of 2.5 sq. mm must be protected by switches with reduced rated current. The most commonly used elements are type B16. But this imposes very strict limits on the amount of current consumed. Otherwise, the switch may trip when more than two heating fields are used.

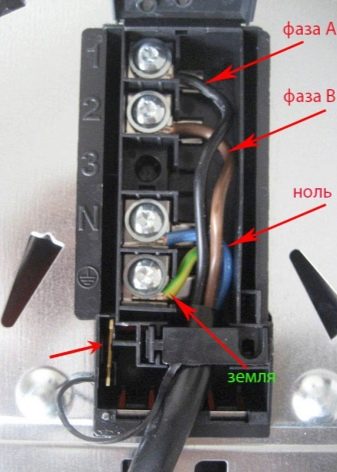

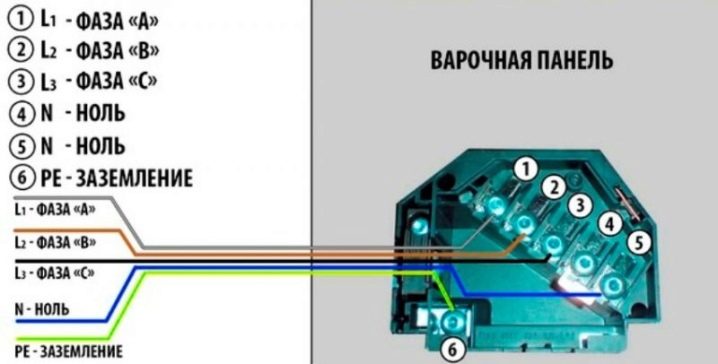

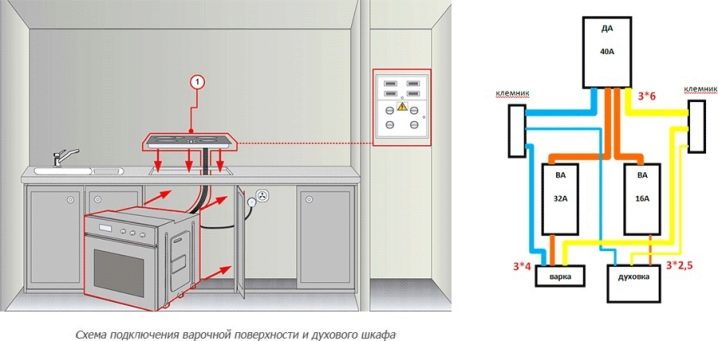

Some induction devices are not connected using wires, but using terminals. In this case, the structure has a special terminal, usually located at the bottom. But there are other situations - for example, when you need to connect an induction hob to a three-phase network designed for 380 V. In this case, instead of three phases, two are usually used. This is the approach used by most manufacturers.

It is quite correct and, moreover, it will be quite simple to connect two heating fields to one phase, and two to the other. In this case, one phase has two average values, and the other has the weakest and strongest current. There is no need to use gray L3 cables in this arrangement. In some cases, there is a need to interconnect the terminals on the board.

This is a very simple task: you just have to use the included board. The wires are twisted with a screwdriver, and this is where the work ends. Here you need to go back to connecting the hobs using the terminals and cover this topic in more detail. The cable ends in a junction box. If there is no cable in the kit, you need to additionally buy an OMY model wire (aka SHVVP).

It will be correct to connect the inoperative phase to the oven. This will load the phase evenly. In some cases, separate cables of 3x2.5 m are used, coming from the distribution devices. Then these cables must be connected to single-phase heavy-duty switches. This solution allows, in case of malfunction of one of the devices, to use another without the slightest difficulty.

Additional nuances

The easiest way to connect an induction hob is in a new home. There it will be possible to independently choose the ideal power of the equipment at its discretion. Usually, 7.2 or 10 kW stoves are connected to single-phase networks.

If you need more powerful equipment, you will have to connect it to all three phases at the same time. But then it will not be possible to use the connection directly to the junction boxes.

It will be necessary to run separate wires from these boxes. They will supply current exclusively to the induction hob.

Important: the wire cross-section must always be at least 2.5 square meters. mm, even in cases where the particular device is compatible with 1.5 sq. mm.

After some time, it may become necessary to install a more powerful technique. And therefore, tenants who immediately install a sufficiently powerful wire benefit significantly - they do not have to redo the work again. Terminal boxes must be at least 100x100x50 mm in size. Saving space is not needed, since the corresponding block will be covered with furniture, and it will not spoil the view.

You can eliminate unnecessary pulling on the wires by making loops at their edges. Spring-loaded terminals for three-phase devices are perfectly acceptable. Their rated current reaches 24 A, which is quite enough. However, in single-phase networks, spring terminals are not very reliable, and it is advisable to use screw-type terminals instead.

What has already been said is enough to unequivocally answer the question of whether an ordinary socket can be used to connect inductive panels or not. The answer, of course, is no.

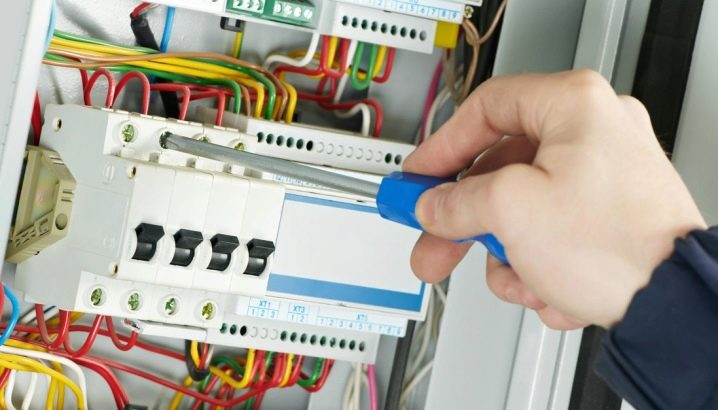

Moreover, even when using special cables, you need to take care of the safety of the hob especially carefully. For this purpose, it is connected through a combination of an RCD and a circuit breaker. Differential machines are sometimes used, designed for a leakage of not more than 30 mA.

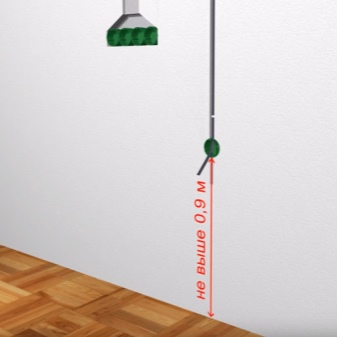

But nevertheless, it is worth taking care of a special outlet, albeit reinforced. Otherwise, you will have to use an electrical panel every time to clean the panel. The outlet is mounted at the height at which it will be convenient. Recommendation: If there is no particular preference, have it stand 900 mm above the floor.

However, you cannot put the socket boxes so that they are flush with the panel; to avoid this, move the installation point to the right or left.

You can see how to connect an induction hob in the following video.

The comment was sent successfully.