All about chimney liner

Chimney sleeve is the installation of a pipe inside a chimney made of bricks. This pipe is made of special materials that are fire resistant. For example, stainless steel. Pipes for sleeves differ in the type of section, and this depends on the size of the chimney, first of all. They are rectangular, square. But this is far from all that you need to know for those who are going to sleeve a chimney.

What it is?

As the brick-type chimney ducts are used, soot begins to accumulate in them, affecting how the draft behaves in the system. Particularly in brick chimneys, the walls are rough, because there, indeed, soot can accumulate, and rather quickly. And the easy destruction of brick systems for the removal of combustion products is not the best in terms of long-term operation prospects. They are affected by thermal shock, and condensation (also appearing due to temperature changes), and the aggressive chemical composition that is present in soot.

What happens due to the accumulation of soot: the traction in the system becomes not ideal, the heating structure starts to work worse, the building is not heated efficiently. But the effect of reverse thrust can also work, because of which the smoke of the house is not excluded. This is already becoming very dangerous. Therefore, the question arises of casing the chimney, or you will have to completely dismantle the old channel and install a new chimney. Obviously, the first option is preferable in most cases.

The ways

And here the owner of a house with a chimney has a choice.

Steel modules

This process is good in that it does not involve labor-intensive dismantling work. The sleeve is very simple, that is, even someone who does not really understand all these engineering communications can handle it. Using steel modules, you can reconstruct stoves and fireplaces, the same chimneys, no matter what kind of fuel they operate on. But the method also has a drawback - steel modules cannot cope with a winding type chimney communication.

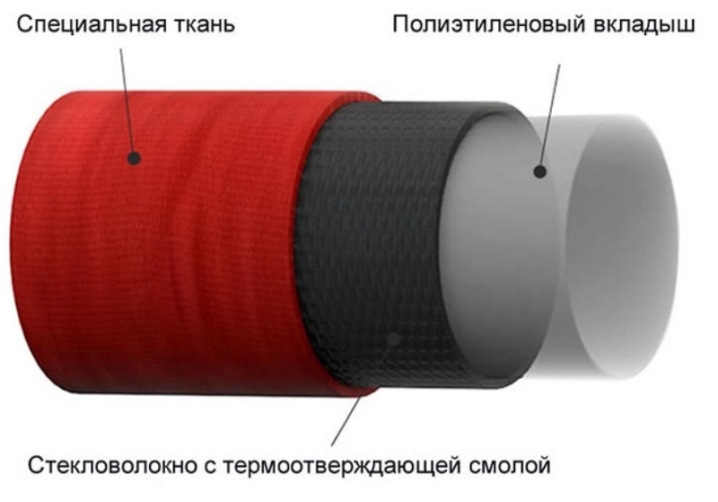

Inserts made of polymer materials

Plastic pipes are mounted inside the brick channel. These are usually fiberglass-reinforced pipes that will be plastic when heated. And thanks to these plastic properties, the material will fill all the deformations of the lumen, and after it cools down, the inner surface of the chimney will already become an almost ordinary smooth pipe. The wall thickness of such a sleeve is about 2 mm. But this method was not without its drawbacks. For example, the temperature limits will be very strict: you will not rise above 250 degrees. Therefore, this method is relevant only for those heating units that run on gas or liquid fuel.

A fiberglass mesh sleeve, tarred, works like this: a complete hose is inserted into the shaft, no connecting elements are used. But shaped parts can be used. The maximum length of such a sleeve is 60 m, and the thickness can reach 50 cm. A similar system has been used for 30 years. It is also important which boiler is being operated, low-temperature or high-temperature - then the components of the sleeve will be different.

Sleeve wrapping is good because a one-piece channel can be obtained without dismantling the brick - this attracts many. The liner is invulnerable to condensation, it bends well even in serious cornering.True, this method cannot be called cheap, and you cannot do everything with your own hands either.

It is worth mentioning also ceramic liners, in terms of strength and durability they are confidently among the leaders. If there is a drilled mine, and it needs to be restored, it is ceramics that is used. Ceramic elements can be round or rectangular. The elements are connected into a socket or by the "thorn + groove" method. The sleeves are used with a diameter of 12-45 cm. Ceramics, on the other hand, are not afraid of soot combustion. But such a construction costs a lot, and it weighs a lot - and these are its main disadvantages. During installation, you will inevitably have to disassemble the mine.

Corrugated Steel Pipe

Such a stainless steel pipe is taken only when the heater does not have a very high fuel combustion temperature. The fact is that the stainless steel corrugated pipe has thin walls, and under the enormous temperature they will simply burn out quickly. It is absolutely impossible to use this option for a chimney in a bath - the fuel in a bath stove burns at very high temperatures.

Work technology

It all starts with standard preparatory activities. First you need to stock up on a powerful flashlight that will help you explore the mine. It is necessary to accurately determine the size of the destruction, the measure of soot contamination, pieces of crumbling mortar and bricks. There are even nests of birds (they often "settle" in chimneys). Then iron scrapers, brushes and other tools are used to thoroughly clean the system. Bricks that protrude from the masonry will not allow the same liner to be inserted, therefore all protruding parts are knocked down. Usually a pry bar or a hammer does a good job with this. Next, you need to measure the length and, of course, the diameter of the chimney, transfer the measured to the diagram with the designation of turns and angular degrees.

It remains to clear the bottom of the mine from construction and other debris, and if necessary, to level it. Then you can buy materials for the sleeve, and proceed to the main part of the work.

Here's how to mount the liner in a small shaft.

-

All parts of the liner are assembled into one system. The joints must be treated with a heat-resistant sealant and wrapped on top with adhesive aluminum tape.

-

Two belts, cables or just powerful ropes are attached to the bottom of the pipe with a clamp.

-

The sleeve is carefully allowed through the shaft until it rests against the bottom zone. With a short chimney length, the lightweight stainless steel pipe is lowered manually, and even cables are not required.

-

From below, the insert must be attached to the boiler inlet, after which a condensate collector is placed. And from the street part, the sleeve is taken out above the brickwork, a protective cap is put on top.

If the chimney is long and curved, the installation of the system will be slightly different. First, the smoke channel is dismantled at the entrance to the boiler, the same is with all sections where the shaped joints are fixed. Then the bottom of the sleeve is assembled from even fragments of the pipe, resting against the first shaped connector. Then the liner is lowered to the bottom of the shaft, where it is connected to the boiler inlet or stove, and a condensate collector is placed below. On the second - while inactive - the tip of the sleeve is fitted with a shaped connector. And so he joins the flat piece of stainless steel, and this scenario continues until a new mine turn. The operation will need to be repeated before the sleeve is removed from the shaft itself.

The section where the pipes are joined must be reinforced with a sealant with heat-resistant characteristics, and then properly wrapped with aluminum tape. Well, it remains to insert the head on top.

How to seal a chimney with a ceramic liner.

-

A roller system is attached to the openings of the condensation tank... The ceramics are very heavy, and you need to lower them 30 cm down, therefore it is safer to use a winch at this stage.

-

The upper end of the condensation container should be treated with a sealant. An even piece of pipe is fixed to the tongue-and-groove system (or bell).

-

To connect the boiler, for example, with a universal fitting, you will have to make a hole in the ceramic sleeve. A fragment of the liner is driven by a winch and goes into the shaft itself. A new element is also attached to the end of the first pipe. In the process of descent, it is necessary to control the moment when the sleeve does not turn with the hole for the fitting in the other direction.

When the condensation collector rests against the shaft bottom, you need to dock it with the boiler inlet. And from above, the ceramic system is brought out above the bricks. The overhang is made equal in height to the cover plate.

A so that during construction, for example, to sleeve a chimney with a polymer sleeve, you cannot do without special equipment. The liner is somewhat similar to a hose that is rolled into a coil. And now the sleeve rises to the roof of the building, is led out through the channel to the mine bottom, supplied to the compressor, and air is supplied. The pressure will cause the soft sides of the sleeve to become smooth. When the sleeve takes on a channel form, steam will appear instead of compressed air. And then the polymer will initially soften, then it will harden. And at the bottom, a container for condensation will collect. On the way from the mine exit, the excess sleeves must be removed, and a head will be placed on top.

Whatever the chimney is used for, it is necessary to ensure that the areas inside the system are not narrowed. The shaped turn is always set to the stop.

And do not forget, if necessary, send bulk insulation to the gaps between the mine walls and the liner.

At the time of construction, the installation of an oval, round or other shape of the sleeve often makes sense: for homeowners this is good, there will be no problems with smoke exhaust. Installing a coaxial chimney sleeve is a procedure that is often required by regulations, and its absence can be fraught with a fine. If necessary, you should contact the companies that are engaged in the sleeve, provide various options for the rehabilitation of chimneys and give all the necessary guarantees.

For information on how to sleeve a chimney, see the next video.

The comment was sent successfully.