All about chimneys for wood stoves

For almost any type of stove, the chimney is one of the main elements; combustion products are removed through it. The choice of the type of chimney, its size and material of manufacture primarily depends on the parameters of the furnace, conditions and frequency of use. With the proper approach to installation and the choice of materials, the smoke exhaust system will not cause unnecessary trouble, the only thing it is demanding for is keeping it clean.

Primary requirements

The combustion temperature of wood is lower than that of coal and gas. Despite this, the chimneys of wood-burning stoves must still withstand heating above 150 ° C.

Most chimneys cope with this task, however, during the combustion process, aggressive substances are released, which gradually corrode the walls. Therefore, experts recommend chimneys made of metals resistant to aggressive environments brands.

The second point that reduces the efficiency of flue gas removal is the formation of condensate on the inner walls. Over time, condensation can lead to blockage of the entire chimney device. To avoid this, the pipe is insulated. The best design for today is the "sandwich". In this case, the temperature of the gases from the furnace equalizes with the environment gradually, so the dew point rarely occurs, and less condensate is formed.

Types of structures

The types of chimneys can be classified according to two parameters: depending on the material of manufacture and on the type of installation.

By type of material, they are:

- brick;

- metal;

- ceramic;

- "Sandwich" - are 2 layers of steel with insulation between them.

By the type of installation, they are divided into external and internal.

External

It is mounted externally and connected to the boiler through the wall.

It is quite simple to install it, you do not need to perforate the floors. It does not eat up the usable area in the house, in addition, it can be installed even after finishing the premises.

However, it is necessary to initially plan an external insulated chimney, provide for its reliable fastening and an aesthetic appearance.

Internal

It is located indoors and exits through the roof.

Serves as an additional source of heat and is less dependent on external temperatures. Such a chimney is usually planned at the design stage of the house. Its biggest drawback is that it hides a significant portion of the interior space.

In modern house building, both installation options take place. Everyone chooses by preference and means.

Materials (edit)

The service life of the chimney is directly influenced by what material it is made of. Various grades of steel are most common here. It is not only the easiest and most cost effective material to work with, but also the most reliable material.

Metal chimneys are made of stainless steel, galvanized and ferrous metal.

Stainless steel

Heat-resistant (withstands heating over 600 ° C) and resistant to aggressive environments steel. It is chosen for its long service life and safety of use. It is recommended to use stainless steel products with a minimum thickness of 0.8 mm. Suitable for residential and technical premises.

Cink Steel

This is an affordable option for a chimney. The metal is covered with a zinc layer, which protects against the negative effects of an aggressive environment. The galvanized chimney has a shorter service life, as it is thinner and requires mandatory insulation.

Black steel

The most budgetary option. Its use can only be justified by a very modest construction budget. Most often, black steel chimneys are installed in summer cottages, small baths, as well as in greenhouses and utility rooms.

Nuances of choice

The optimal choice of chimney for a wood-burning stove depends on many parameters.... Situations are different both with the premises - maybe capital construction of a residential building, or maybe just a temporary hut for seasonal work, and with the oven itself - the usual convection type or long burning.

Consider why this or that type of chimney is better suited, and what are the advantages and disadvantages.

Brick chimneys are durable, suitable for installation both in a large private wooden house and in a cottage, where the heavy weight and massiveness of the product will not be felt.

However, modern boilers increase the load on this type of chimney; installation of additional metal liners is required. In general, the installation of such a product is rather complicated and requires high qualifications of a bricklayer.

Metallic - inexpensive and pre-fabricated chimneys. Lightweight, suitable for small living quarters, baths and technical buildings. They have a short service life - no more than 15 years.

Ceramic - leaders in terms of service life (more than 50 years) and heat resistance (withstand heating over 550 ° C). Great for fireplaces. Roads in production are fragile and require a foundation.

"Sandwich" - has the same performance characteristics as metal. However, it is more resistant to condensation and corrosion, but more expensive. It has a wide range of applications - from a wood stove to a gas water heater. It can be easily mounted both in the finished house and outside. There is a wide range of factory items on sale.

Payment

To make the correct calculation of the length and section of the flue system is more than half of the job, at least the most important part of it... Mistakes at this stage can lead to disastrous results and affect the whole house.

Most often, and more correctly, people try to outsource this work to professionals. However, for a general understanding of the process, you need to know the following.

For the correct calculation, a huge range of data is used - from the characteristics of the firebox to natural materials. There are 3 main techniques.

- The exact method. Performed by qualified professionals. Basically, this is a special department for the production of boilers. They use experimental data and professional equipment.

- Indicative... Based on calculated ratios, graphs and charts. Such a calculation can also be performed by a layman. However, you need to have access to the normative values.

- Online method. Allows you to calculate everything using electronic applications. It can give a quick and high-quality result, however, it requires a scrupulous introduction of a large amount of accurate data.

Installation tips

The saying “if you want to do well, do it yourself” is not always and not always applicable. But there are times when there is no suitable specialist nearby, or his services are prohibitively expensive, then you have to work with your own hands.

In order to independently mount the chimney, you need to delve into all the details of this process as carefully as possible. After all, an assembly error at any stage can become critical.

Preparation

- Pre-clean all the passages and fixings of the chimney.

- Make the necessary holes in the desired shape.

- Take care of the sealing and thermal insulation of the outlet openings.

High-altitude work

When installing an internal flue gas vent:

- you need to take care of a safe and comfortable stay on the roof;

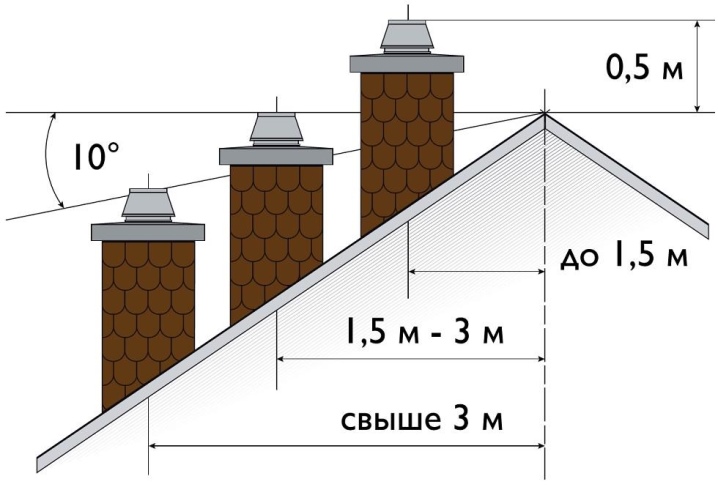

- take into account the parameters of the outlet, taking into account the load-bearing frame and the angle of inclination.

When installing an external chimney:

- it is important to securely fix the pipe, taking into account the wind load;

- take into account the average annual indicators of the wind rose in the area.

Important points of technology

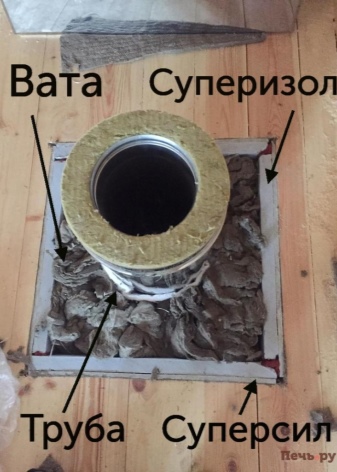

- When passing combustible floors, it is imperative to use sandwich elements or additional protection with non-combustible materials.

- Take care of the support and strengthening of the structure, taking into account its weight.

- Coat the joints with heat-resistant sealant and secure with clamps

- The elements must be selected in such a way that the joints do not fall inside the floors and walls.

Protective elements

Pass-through box

When passing the chimney through a wall, ceiling or roof, it is recommended to make a protective duct. This construction of metal and non-combustible mineral wool will help to guide the pipe correctly and safely into the outlet. TOThe box can be assembled independently based on individual dimensions and needs. Its assembly scheme is simple, however, you need a cutting and welding machine.

Head

The final element of the smoke exhaust system is designed to prevent precipitation from entering and wind-blocking the channel, as well as to protect the insulation from getting wet.

What else do you need to know during installation?

For self-installation, you must strictly follow SPiP 41-01-2003 "Heating, ventilation and air conditioning".

- The diameter of the flue duct must not be less than the diameter of the furnace outlet.

- The channels must be carried out strictly vertically.

- The minimum duct length from the air intake is 5 meters.

- There should be no horizontal bends in the attic for cleaning.

- The chimney should not be in contact with other technical communications at home.

- The surrounding elements must not be allowed to heat above 50 ° C.

The comment was sent successfully.