Features of I-beams 25SH1

An I-beam of denomination 25 is noticeably larger than a similar product of the 20th. It is performed, like all of its brothers, in the form of a transverse H-profile. This solution provides optimal strength parameters for most load-bearing structures in private residential construction.

general description

I-beam 25SH1 - a reference to wide-flange H-profiles. The wider the shelves, the more efficiently they distribute the weight load on the walls below, both from their own weight and from the residual weight of building materials (reinforcement, concrete) filling the rest of the ceiling.

Like conventional T-shaped sections, I-beams are manufactured from the same steels. - 09G2S (has improved characteristics), St3, St4. Corrosion-proof and some high-alloyed alloys are not used in the production of U-beams and I-beams - only with rare exceptions that are permissible according to the special requirements of the customer.

The production of I-beams, including 25SH1, is based on hot rolling. First, a steel alloy is smelted from the ore - it undergoes the necessary purification from impurities harmful to it, for example, excess phosphorus and sulfur are removed. The white-hot liquid alloy is cast into special molds. Then, after cooling down and starting to solidify, the steel goes through the main stage of rolling. Cold-rolled I-beams are not produced - the specificity of rolled products is not quite the same, and this is what makes it different from a channel.

The wide sides of the I-beam allow it to be used as an intermediate solution between the normal and columnar I-beams.

Thanks to this difference, a significant resistance of this element to the bending action applied from above is provided.

Specifications

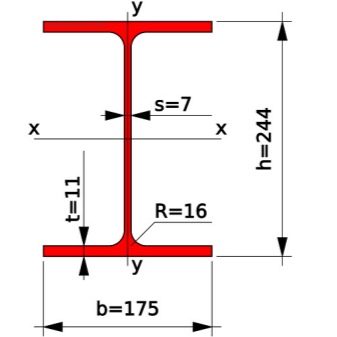

The parameters of the I-beam 25SH1 are expressed by the following values.

- The total height of the main strip is 244 mm, with the thickness of the side shelves.

- The useful height of the main wall is 222 mm.

- Profile width - 175 mm.

- The width of the side edge, excluding the main partition, is 84 mm.

- The radius of curvature on the inside is 16 mm.

- The thickness of the main partition is 7 mm.

- Shelf sidewall thickness - 11 mm.

- Cross-sectional area - 56.24 cm2.

- The number of moldings per ton of products is 22.676 meters.

- The weight of 1 running meter is 44.1 kg.

- The radius of gyration is 41.84 mm.

To calculate the weight of a batch of goods, in order to obtain the mass of 1 m of an I-beam, the density of steel is multiplied - for St3 it is 7.85 t / m3 by the actual volume. That, in turn, is the product of the sectional area by the height (length) of the workpiece. I-beam 25SH1 is produced in the form of an element with strictly parallel side edges. The characteristics of these products are reflected in GOST 26020-1983 or STO ASChM 20-1993. Cuts of the 25SH1 profile are produced in the form of 12-meter blanks.

According to GOST, a slight - by a fraction of a percent - excess of the length (but not a decrease in the same value) is allowed in comparison with the nominal value in the price list of the supplier. The 12-meter section weighs approximately 569 kg.

In addition to the steel grade St3, the designation S-255 is used, which is, in fact, the same. Steel S-245, low-alloy composition S-345 (09G2S) - in this case, an alternative designation.

The rigidity of the I-beam 25SH1 is at a decent level due to the increased width of the sidewalls. Due to such dimensions (in cross section), the 25SH1 beam will not bend and will not fly out of its place even under significant loads, and the wall (upper masonry row) will not suffer at all.Beam 25SH1, like all of its similar counterparts, is not suitable for installation as a supporting structure of a ceiling on walls made of highly porous building materials (foam, aerated block) without preliminary reinforcement by means of a reinforced concrete reinforcing belt (armomauerlat).

Flexibility index of low or medium alloy, low or medium carbon steels - for any size and assortment of I-beams - it has a certain margin. This allows the beam not to break under impulsive (peak moment of force) or smooth (alternating) compression. If, nevertheless, the permissible load is exceeded several times (a certain supercritical level), then the 25SH1 beam will either bend and slip out of its place, or destroy the upper rows of the masonry. The surface area (adhesion to concrete), even in the absence of ribbing (as on reinforcement), allows you to create a reliable adhesion, for example, to concrete.

Application

The use of the I-beam 25SH1 is primarily limited to construction tasks. In construction, it is an element of strengthening the foundation and floors. The frames of shopping and entertainment centers, industrial buildings, apartment buildings are mounted from an I-beam. Due to the facilitated machinability - welding, cutting, drilling, turning of 25SH1 elements - it is easy to weld and / or tighten the supporting structure of any plan with bolts and nuts. Before welding, the elements must be cleaned to an even metallic sheen.

In addition to the construction of buildings and one-story structures, bridges, ceilings, an I-beam with a nominal value of 25 is used as non-bearing structures of the same objects. For example, by placing a partition channel vertically, it is easy to mount drywall on it, filling the interior space with insulation after painting the I-beams.

An I-beam structure has been standing without any problems for a hundred or more years - subject to the optimal humidity regime and proper maintenance.

Car building, as one of the branches of mechanical engineering, often uses channels and brands. A rolling stock in its construction is inconceivable without professional pipes, channels, angle profiles and (two) T-bars. The I-beam, along with closely related profile rolled products of other types, will create a reliable basis for attaching the component elements to each other.

But the I-beam 25SH1 is also used for wheeled vehicles with springs and pneumatic tires - from bulldozers to oil tractors. Trucks for a KamAZ trailer are a typical practical example of the use of a T-shaped frame, which sets the main reserve of rigidity and strength in a payload (transported cargo) of up to 20 tons, including the second trailed trucks.

The comment was sent successfully.