Features of I-beams 20SH1

An I-beam is a hot-rolled product, as if composed of two others. The difference between a T-bar and an I-beam is not the double thickness of two of the four opposing walls formed when the T-pieces come into contact, but a single one.

general description

I-beam 20SH1 - rolled height equal to 20 cm, with wide shelves. In fact, I-beam is a cross-section in cross-section, reminiscent of a turnstile structure in the form of a similarity to the "+" sign, the width tolerance of which is normalized by the corresponding state standard. The I-beam is referred to as I-beam profiled steel. Marker Ш1 indicates the first denomination in the dimension of the profile element.

But the I-beam may not look like a cross in cross section, but on the letter "H" lying on its side, while the walls, perpendicular to the so-called shelves, are directed against each other and spliced. If necessary, such an H-profile can be cut neatly along - you will get two identical T-profiles.

The feature of the double T-piece is that it acts mainly on bending. The width of the main bulkhead wall is approximately equal to the width of the side walls. The inner edges are equal.

Features of production

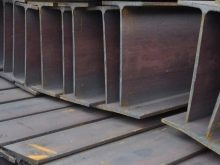

I-beam 20SH1 is produced using the technology of hot rolling of billets, previously heated to a certain temperature. The technology was based on bloom, which was replaced by the continuous casting method. Heating the workpiece allows the steel to soften, which makes it possible to form its basic outlines, shape, using rolling shafts. The essence of hot rolled products is high-temperature metal-plastic processing, namely: flattening of a metal blank into a pancake or strip. In this case, the cross-sectional area decreases, the transverse outlines change, but the value of its length increases. Depending on the specifics of production, the beam undergoes revision with accelerated cooling.

The composition of St3Sp or St3GSp, 09G2S is used as a steel alloy. When choosing an I-beam 20SH1, the supporting structure requires the selection of the best alloy that can withstand the bending load. The highest in terms of the requirements for the load component are the units used for the roof and as interfloor load-bearing beams.

Steel-3 is well welded and drilled, turned - this gives the craftsmen the opportunity to combine bolted and welded joints, or use each type of joint separately.

Specifications

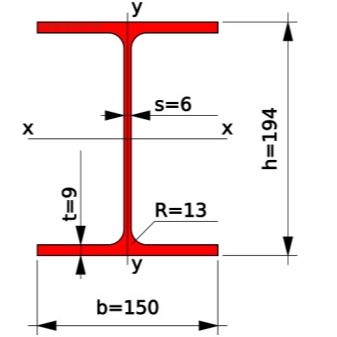

Russian production is based on the document GOST-R 57837-2017, which replaced the Soviet standards GOST 8239-1989, which regulated the manufacture of an I-beam element with shelving edges inclined to each other. The documents indicate the total height - taking into account the thickness of the shelf edges - 194 mm. The width of the equal-shelf profile is 15 cm. The thickness of the main wall is 6 mm, the thickness of one shelf is 9 mm.

The rounding of the radius at the transition from the bulkhead wall to the sidewall is 13 mm. The weight of 1 running meter of an I-beam is 30.6 kg. The density of the steels is taken to calculate the mass of the element, averaged - only 7.85 t / m3, this helps to quickly determine the assortment and order the batch of I-beams required for the construction of the facility.

The advantages of 20SH1 beams are as follows.

- The design is highly resistant to dynamic alternating loads.

- Reduced mass - in comparison with similar units with a different cross-sectional shape with approximately equal strength values.

- Transportation and storage of elements without significant problems both for warehouse workers and the delivery company as a whole, and for customers and the developer, whose craftsmen carry out the entire range of construction work.

- Economical application: the price of I-beams is significantly reduced compared to classic T-beams.

- You can combine two or three I-beam mounting technologies. For example, gas and arc welding (electric welding) - in combination with bolted hardware.

- High rigidity of the assembly.

- Low creep, invariability of linear dimensions.

However, the I-beam in the form of an H-profile also has disadvantages.

- You cannot saw an I-beam into two single tees - bending strength will be lost, it is better to purchase ready-made tees for those construction locations where it is really necessary.

- Inability to strengthen the metal structure with a continuous arrangement of two tiers of an I-beam. The fact is that it is impossible to catch on the smooth and smooth transitions between the main and side walls without using a continuous weld penetration of the seams.

If necessary, immediately get an I-beam of a different denomination - with a greater height and thickness of the shelves and the main strip. The wide-flange I-beam, due to the larger area of the side strips, better distributes the load on the surface on which it rests according to the project of the object.

These features make it possible to save the erected frame from inept alterations.

Application

The main field of application of the I-beam 20SH1 is construction. I-beams are well suited for the organization of interfloor floors, attic-roof and hinged supports, stairs and other capital structures, the load on which is very significant. In the engineering industry, they are used as elements of frame supporting structures, on which the sheathing is placed. For example, the production of trucks and SUVs is not complete without industrial pipes and (two) brands. Since ST3 steel is cooked just fine (it is low-carbon), the use of an I-beam in combination with a profiled pipe as part of welded and bolted-and-nut structures gives excessive load values, which fully fits into the parameters of a truck loaded to the limit. The running and supporting structures of such machines operate without overhaul for a number of years until fatigue stresses exceed a certain critical limit.

Loading parameters depend not only on the thickness and width of the walls, but also on the length of the beam: too long will "spring" and quickly bend - even when exposed to the same weight when comparing the longer and shorter parts. The use of more high-alloy steels will not save from breakage when the calculated length and weight load are exceeded: the high-alloy structure is more "springy" and less deflects, but this does not mean that cracking is excluded. With the accumulation of fatigue stresses in the 20SH1 beam, as in similar elements, fatigue stresses accumulate, leading to the formation of microcracks long before the beam cracks so much that it begins to break. Therefore, the dimensions of the beam when designing structures - especially load-bearing ones - should not exceed the calculated ones.

The comment was sent successfully.