Recommendations for the selection and installation of locks for glass doors

Due to the growing popularity and widespread demand for glass doors, the question of choosing locking devices for them is more than relevant. The modern manufacturer offers a wide range of locks with a huge variety of modern and functional models.

Peculiarities

Structurally, door locks are noticeably different from their counterparts designed for installation in wood and metal canvases. This is due to certain requirements for locking mechanisms dictated by the specifics of the operation of glass doors. First of all, this applies to the appearance of the structure, the details of which are always in sight and clearly visible through the glass sheet.

At the same time, the products must provide no less protection for the premises than their traditional counterparts. Therefore, the manufacturer of locks faces a difficult task to ensure both the inviolability of the space and the harmonious combination of the lock with the design of the room and the canvas. In general, all glass door fittings should be made in the same style, therefore, a competent choice of a locking device is an important and responsible matter.

Varieties

Glass door locks are classified according to a number of characteristics, the most important of which is the method of installation. According to this criterion, products are divided into two large groups and are represented by mortise and overhead devices.

- Mortise locks characterized by the complexity of installation, coupled with the fragility of the glass sheet. Even with a door thickness of 10 mm, the process is technically difficult and cannot be performed without the help of special equipment. In such cases, glass is treated with special compounds that increase its strength, however, even in this case, there is no complete confidence that the canvas will fully retain its performance characteristics after mechanical action. The case of the mortise lock consists of two parts, installed overlay on both sides of the door leaf and connected with through fastening hardware.

Structural mortise locks are subdivided into three more types. The first one is represented by cylinder models, lockable with a key and possessing high burglar-proof qualities. The second type is a latch that functions thanks to a return mechanism controlled by a spring. These models can be opened using lever handles or rotary handles and are often equipped with a lock. The principle of operation of the locking device is as follows: when you press a button or lever, the door is reliably locked, and it is not possible to open it from the back side. Models are often equipped with a key-operated pull-out deadbolt. The third type of locks is represented by mechanisms with a counterpart and is used for mounting on double-leaf doors. The lock consists of a body, equipped with a cylinder mechanism, and a counterpart designed to slide the C-shaped bolt onto a special pin, which is in a horizontal position inside the striker.

The advantages of mortise locks are: complete concealment of mechanism parts and high resistance to burglary. The disadvantages include complex installation with the need to use a special tool, as well as extensive experience with glass.

- Overhead models are presented on the market of locking devices in a wide range. Products are an excellent alternative to mortise type locks and are installed without drilling the blade. Fastening of devices is carried out using mounting strips having a L- or U-shaped structure. In such cases, the glass sheet is clamped between two mounting surfaces, which are attracted to it by means of fastening screws. To preserve the integrity of the web, a polymer gasket is installed between the glass and the mounting strips. This type of fastener allows you to install a patch lock on any thickness of the canvas, without fear of damage or cracking.

Surface models are the most numerous group of door locks and are represented by mechanical, electromechanical, electronic and electromagnetic devices.

- Mechanical products, in turn, are subdivided into four types. The most common among them are models with latch and roller latches, often equipped with latches and available on the market in a wide variety of colors, textures and designs. The following two types of mechanical locks - cylinder and rack (crossbar) models - provide high protection of premises and are locked with a key. The latter type is presented by combined models that combine a latch and a cylinder or rack lock.

- Electromechanical locks They are used for pendulum glass doors and are distinguished by the presence of an electric drive that drives the locking bolt. The mechanisms are rather large, which is why they are not in great demand. In addition, the models are quite expensive and completely volatile.

- Electronic locks are opened by entering a digital code, they do not require the use of keys and are often equipped with a touch screen. Especially technologically advanced models can be opened by a signal from a remote control or a mobile phone. This allows you to significantly limit the circle of persons who have access to the premises.

- Electromagnetic locks they function thanks to the installed magnet and can be installed both vertically and horizontally. Installation is carried out on the upper or lower part of the leaf or above the doorway. The principle of operation of electromagnetic locks is as follows: when the doors are closed, in one of which there is a core, and in the second - an anchor, a powerful electromagnetic field is created, which keeps the door closed. When the button is pressed, the network is opened, the effect of the field weakens, and the door opens.

How to choose?

The choice of the lock depends entirely on the type of door structure, functional load on the leaf and the place of installation of the door. So, for all-glass office swing doors, a rack or cylinder combination lock is quite suitable. Such a device will reliably protect the premises in the absence of employees, and a latch will fix the door during the working day. For pendulum blades, you can purchase a rotary-type mortise lock, in which, when the key is turned, the tongue will unfold and be fixed in the counterpart. For sliding systems, a latch and a central patch lock are perfect.

Another important criterion for choosing a lock device is the functional purpose of the door. So, if the swing door is located in a place with high traffic, then it would be wiser to install a lock with a roller latch. Such devices operate very quietly, open easily and easily lock in the closed position. A magnetic lock is also suitable, which starts to work even if the door leaf is incompletely closed, pulling the sash into place. This is due to the large force of attraction of the magnets, which in this case play the role of closers.

An important factor in choosing a lock is its compatibility with the rest of the door hardware and with the overall design of the room. However, with a wide variety of models in gold, silver, chrome and bronze, making the right choice is easy. You should also take into account the external conditions in which the product will be used. So, for rooms in which the humidity level reaches 95%, it is necessary to purchase models with anti-corrosion spraying. Operational restrictions apply to electrical models as well. With a particularly high level of humidity, it is not worth buying devices that run on electricity. In such cases, you can limit yourself to overhead or mortise mechanical products.

How to install correctly?

Installing a patch lock is considered a fairly simple process and can be done independently. The body of such a device is equipped with a special plate, which is put on a glass sheet and fixed with fastening screws. With the installation of mortise models, everything is much more complicated. Their design involves drilling the door leaf, which must be done by professionals.

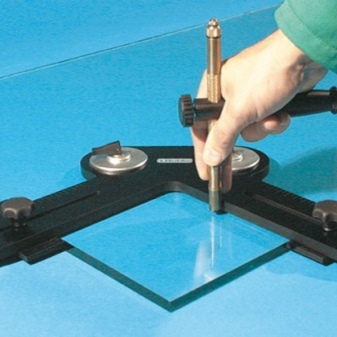

To form the holes, it is necessary to use carbide burs with diamond heads, and the drilling process should be performed in smooth circular movements, moving from the center to the edges of the hole being formed. It is advisable to use a fan that will promptly remove glass dust from the working area. This is necessary in order to control the operation of the bur and not to make a larger hole. Otherwise, the fasteners will dangle in the socket, which over time will lead to a violation of the integrity of the glass sheet.

During drilling, it is required to cool the tool and glass in a timely manner using a special emulsion. If this tool was not found, then you need to constantly check the working surfaces, and in case of overheating, suspend work, thereby allowing the tool to cool down. After the holes are formed, you can start installing the lock on the canvas. Only those hardware that was supplied with the mechanism should be used as fasteners.

A competent choice and correct installation of the door lock will ensure reliable protection of the room and give the glass sheet a modern and aesthetic appearance.

You will learn about the electronic lock for glass doors in the video.

The comment was sent successfully.