Varieties of door seals

The sealing tape has more than just the function of protecting the home from drafts. In the fight against extraneous sounds coming from the street, the seal can also play an important role. When choosing, it is worth paying attention to several aspects: the types of seals, the materials from which they are made, and also use tricks that will help you choose the right door insulation.

Functions

The most important function of the seal is draft protection. If the device does not cope with this task, it is a priori of insufficient quality. This is especially true for entrance doors: thermal insulation is extremely important in this case, and only a sufficient level of insulation can provide it. An important heat-insulating function "works" in both directions, at the same time protecting the apartment from the cold wind from the street or from the entrance and preventing heat from escaping from the home. It is estimated that doors that are not equipped with a seal release up to 40% of the total heat generated by heating devices. Heating prices are currently quite high, so no one wants to waste precious heat.

Speaking of thermal insulation, one cannot fail to mention that a number of products can withstand significant temperature fluctuations. The amplitude can vary from -65 to +95 degrees Celsius. Thus, having installed high-quality insulation on the front door, you can not worry that it will crack in summer or winter.

Another plus of the seal is its soundproofing properties. They are inherent in both metal water doors and interior doors. It so happens that the front door comes out just next to the road or playground, and the insufficient level of sound insulation does not allow residents to feel comfortable enough, because annoying sounds from the street greatly interfere. If the rooms are not well isolated from each other, then another problem arises: the impossibility of everyone doing their own thing without the risk of interfering with the other. Good noise isolation makes situations comfortable when, for example, they are playing the piano in one room and reading in another.

Shock absorption is another important factor. Everyone has come across a situation when in summer, due to open windows, drafts are walking around the house, and the doors are closed with a strong bang, disturbing not only the residents of the house, but also their neighbors. The sealing tape hides an unpleasant sound, preventing the creation of annoying pops, as well as extending the service life of the door and door frame (they wear out faster due to sudden slams).

The seal protects the house well from unnecessary odors or smoke. For example, something might burn in the kitchen. Nobody wants the "aroma" of burning to instantly spread throughout all rooms, so the insulation will help keep the smell only in the kitchen. The same can be said about the bathroom door: it is better to leave wet steam directly within the bathroom and not let it out into the hallway or corridor.

Thus, the main property that the door seal carries is the door leaf sealing. In the Russian climate, this property of the door is extremely important due to the strong temperature changes on the streets. Moreover, you should carefully consider the choice of the product if you live in a big noisy city, because many megacities are very busy both day and night.It is for such "sleepy" cities that doors with seals for enhanced sound insulation are well suited. When choosing a door to the kitchen, you also need to make it as tight as possible, because it is far from always appropriate and pleasant when the smells of food are heard, for example, in the bedroom.

Views

Seals are classified according to several criteria. The first is the door view:

- For entrance doors. The sealant for entrance doors is usually made tubular. The profile with a cavity inside completely ensures a sufficient fit of the door, contributing to complete isolation from external influences.

- For interior doors. Here, completely different requirements are imposed: there is no need for such a strong protection of the room from the environment, the aesthetic component comes first. Isolation is important in some cases (eg in the bedroom) but not required.

- For plastic doors. Seals for plastic doors are placed in a separate category, since they differ significantly from seals for ordinary doors. It is necessary that the groove element reacts well with the environment. As a rule, such seals are placed on balcony doors. Please note that, as a rule, only a part produced by the same manufacturer as the door itself is suitable for a plastic door.

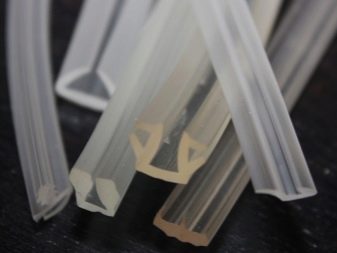

- For glass doors. The profile that is attached directly to the glass can be aluminum or silicone. Silicone elements must have a special section, they also immediately serve as a heater, while a special rubber seal must be made on the aluminum profile. Silicone glass seal is suitable for rooms with high humidity, since there is no risk that it will "come off".

According to the materials, the following types are distinguished:

- Rubber.

- Silicone.

- Foam rubber.

- Magnet.

- Thermoplastic.

- Felt.

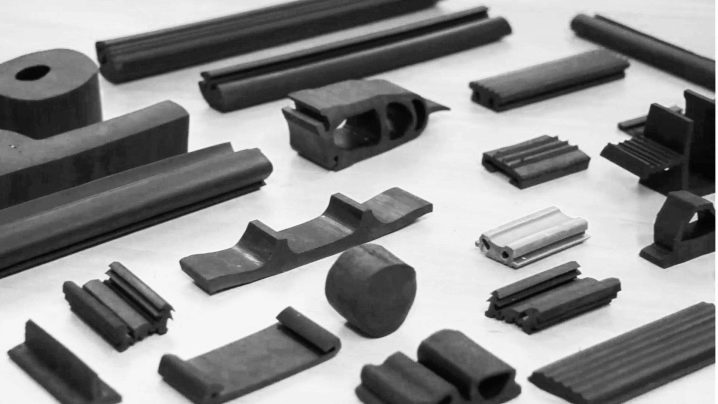

By configuration, the following types are distinguished:

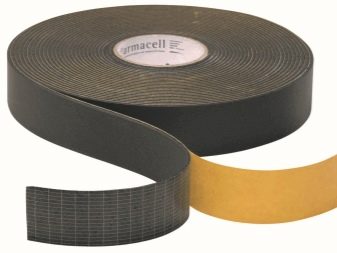

- Tape. It is a soft cord with a rectangular cross section, the width of which is approximately 9 mm.

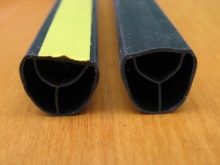

- Tubular. Despite the fact that a tube seal is most often used for entrance doors, it boasts less sealing properties than tape models. It is a hollow tube inside, which is pressed when the doors are closed, due to which there are no gaps between the door leaf and the frame.

- Groove. Made specifically for plastic doors, it is a hollow profile made of soft rubber, on one side of which there is a special brush installed in the grooves. Thus, the effect of the external environment on the seal is reduced and is almost completely transferred to the door leaf itself.

- Spring loaded. Attaches to the door frame, not the door. When closed, its parts slide along the spring and close the slots. Only suitable for fastening on perfectly flat surfaces.

- Mortise. Made for wooden doors. A small niche in the door frame is specially cut out for such a seal, which allows the door leaf to be tightly fitted in the future. A rubber profile is attached to the niche.

- Folding. Suitable for sealing folding doors, accordions and similar structures.

Tape seals are rarely made wider than 10 mm. This is due to the fact that such a width is optimal both for attachment around the perimeter of the door leaf and for the door frame. Tubular variants generally have the same characteristics, regardless of what material they were made from. The size of the seal for a plastic door depends entirely on the manufacturer. It often happens that for each specific door model only one model of seals is suitable, and there is no way to replace it with an analogue. It is recommended to pay special attention to this issue when choosing a door, whether it is possible to replace parts with ones purchased from another manufacturer, otherwise, during repairs, it may be necessary to change the entire door.

A complex rubber profile, suitable for both interior doors and entrance doors, remains a universal choice. It is produced in various versions, it can be made of soft rubber or from a denser one, the width of the profiles is traditionally 8-10 mm.

- Foam it is better not to use the element for entrance doors and save it in case of interior structures. The fact is that foam rubber is not the most durable material and will simply not withstand the kind of exploitation that the front door is subjected to. Foam rubber is quite cheap, while it copes tolerably with the main functions of the seal. It is best to use foam inserts for doors that are exposed to little use, for example, in a hall.

- Unlike foam rubber, magnetic constructs are only used for front doors. Magnetic inserts on soft rubber profiles guarantee the best fit of the seal, so that protection against drafts or heat leakage from the house is guaranteed. Problems can arise only with the installation of elements, they must be matched exactly to the size of the door, otherwise the magnetic protrusion will simply not allow the door to close.

Another relevant option is colorless insulation. Many people think that they are a good solution only for glass doors, however, this is far from the case. The transparent seal looks great on wooden, plastic and metal doors, as it is practically invisible. Thus, it can be used in cases where the owner is afraid to spoil the aesthetic appearance of the door or if from a stylistic point of view, the use of a seal is inappropriate.

According to the texture, the following types are distinguished:

- Flexible. Smooth or flexible profiles can be made from many different materials, including rubber, silicone, magnet.

- Liquid. It is usually used for insulation of entrance doors. It is a kind of liquid foam rubber, which is applied to the desired areas under the influence of pressure.

- Pile. The fleecy version is very familiar to many, since it was felt that initially was the only alternative for the manufacture of insulation for the door. At this stage of the development of the repair business, a tourniquet and tape are produced not only from pure felt, but also from synthetic fleecy cloth.

By location, the following options are distinguished:

- Threshold. They are a good solution in cases where the door design does not provide for a threshold. Basically it is done on automatic control, which allows the profile to "adjust" to the width of the gap between the door and the floor in the open or closed position.

- Contour. Outline options are the easiest to understand. They are attached along the entire perimeter of the door leaf or frame, at the same time eliminating gaps everywhere. Most often used for entrance doors, a triple profile is taken.

- Fireman. Such a thermally expanding version is a substance that turns into foam when strongly heated. The foam completely seals the door, preventing the passage of smoke and preventing oxygen from reaching the fire.

Dimensions (edit)

Depending on the type of seal, its dimensions also vary. Also, the optimal size depends on the gap, how thick it is. The overall footage of the door structure, as well as the features of the purpose of the door, also plays a significant role. For example, for entrance doors, a denser and wider insulation is required. Flexible rectangular profiles are sold in large rolls, the size of which depends only on the manufacturer. They are perfect for eliminating narrow gaps that do not cause much discomfort to the owners of the door.

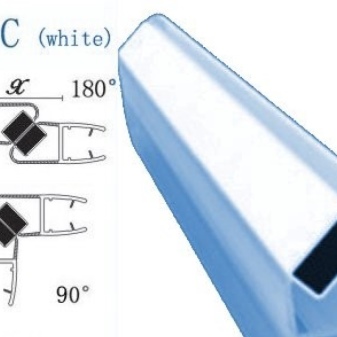

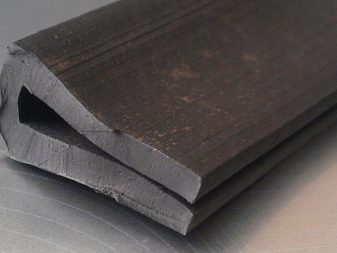

In some cases, rubber profiles of complex configuration are used. They are suitable for ordinary doors and even for super-heavy armored doors. Each of the profiles has its own special shape: C, P, O, and so on.Each of the shapes is designed for gaps of certain dimensions, however, remember that these profiles serve to insulate gaps with a width of 1-4 mm, but some shapes are good for insulation and larger gaps.

- Profile shapes C, K, E are suitable for masking small gaps up to 3 mm.

- The P and V shapes are perfect for masking liquids up to 5 mm.

- Less commonly used are the O and D profiles, which allow you to work with gaps up to 7 mm.

When calculating the required amount of a flexible profile for door insulation, keep in mind that you will definitely need at least 5-6 m of material. It is always better to take a soft seal with a small margin, since if suddenly a part of the installed profile deteriorates, it can always be quickly changed. Rigid seals are made directly to the size of the door. As a rule, independent measurement and acquisition causes certain difficulties, so it is better to contact the professionals with this question. There is only one seal on the market that requires such a delicate selection - this is the magnetic option.

Seals differ in thickness. For interior doors, soft, thin profiles are selected, while entrance doors need more impressive insulation. Thick rubber profiles, often multi-layered, have impressive dimensions compared to miniature interior designs. Thus, when choosing a seal of the required size, it is imperative to focus not only on the type of seal, but also on the functional purpose of the insulated door, on the size of the existing gaps. Pay attention to where the element will be attached: along the perimeter of the door frame or directly on the door leaf. Traditionally, thicker versions are mounted on the door frame than on the door itself, since when installed on the door frame there is little risk that the door will simply not close.

What is the best seal material?

At the moment, there is a huge range of materials from which door seals are made. Having familiarized yourself with the characteristics of each of them, you will be able to determine exactly which option is right in your case.

- Rubber the seal is perhaps the most popular today. This is due to the versatility of the material, since it tolerates temperature extremes, high humidity and other negative influences well. So that bacteria do not multiply at the joints or fungus does not appear, the rubber is pre-treated with a special compound that prevents the activity of bacteria and disinfects the surface.

- Silicone option - a good alternative to the rubber seal. Mostly silicone is used for insulating glass doors, since it is firmly glued to the glass, you just have to moisten it with water and let it dry. Silicone does not crack under the influence of strong temperature changes and does not stick off glass. Silicone elements are much better than rubber ones, they are suitable for rooms with high humidity, such as a bath, sauna, bathroom.

- Modern TPE seals... They are distinguished by their ability to adapt to extremely high or extremely low temperatures. Sometimes the spread can be more than 100 degrees - from -70 to +95 degrees Celsius. The European formulation of thermoplastic elastomer guarantees high reliability, long service life, good shock resistance, low profile deformation during operation.

- Felt is the most traditional and familiar material from childhood. Due to the fact that felt to this day is made of natural wool, it protects the room well from the cold and is on the list of leaders in many respects because of this.Throughout the entire service life, the felt insulation does not lose its original properties, it tolerates the harsh Russian weather realities well, and conserves heat. Contrary to popular belief, felt is completely fireproof, since it has a very dense structure, due to which it does not burn well.

What are the colors?

Today, seals are produced in a variety of colors, which include not only the classic black or white color. It is possible to choose the necessary model for a door of any shade, whether it is a plastic balcony swatch in white or a bright door to the nursery. However, it is the white and black options that are most popular with consumers. White models are selected mainly for plastic doors, when the owners need to decorate some cosmetic flaws. Also, white seals look good on interior options, while on the front door it is unlikely that a white element will look appropriate.

For the front door, on the contrary, black insulation is the best solution. Black models go well with almost all types of metal doors, and this fact should be taken into account. In addition, painted rubber insulators for entrance doors perform worse with their functions, since the paint significantly changes the chemical composition of the material. The same can be said for plastic balcony doors. It is best to choose a black seal, it will maximally protect living rooms from a draft outside.

There are a great variety of color models. There are no texture swatches or patterned options, but the color choices are almost unlimited. The most popular is the entire gamut of brown shades, since seals are often selected for wooden doors, and people try to choose them so that they are as invisible as possible on the door leaf, and do not spoil the overall impression. Please note that it is often offered to immediately equip the door with a suitable seal of the desired color for a relatively small fee. As a rule, this option is more preferable, especially if you know in advance that you need to install such a plug for the slots. The decision to buy a door with a ready-made sealing element will greatly save you time and effort that you would have spent looking for, and will not hit your budget hard.

Whichever color of the seal you choose, remember that the overall appearance of the room and the door separately should remain harmonious, however, it is much more important that the chosen sample does well with its main functions.

How are they fixed?

There are several options for attaching the seals. Each of them is due to the type of fastening with which a particular option is equipped.

- Installation in the groove. The profiles for fastening into the groove are equipped with a special fastening-brush. For installation, you do not need additional materials, however, this does not make the installation of such elements the easiest. The main difficulty that most people have when working with groove seals is adjusting them to the required size. It should be understood that rubber is a material that stretches easily and just as easily takes its original shape, therefore, when cutting or pressing directly into the groove, you cannot pull the product directly into the groove, on the contrary, you should "pick it up" a little. Trimming the groove seals should be carried out after they have been installed in place, otherwise there is a high risk of cutting off the excess, and this will inevitably nullify the entire effect that was planned to be obtained through the installation of the elements.

- Self-adhesive option. Installation with self-adhesive tape is usually the least difficult. As in the previous case, the only equipment that you will need is a painting knife, with which, after gluing, you need to cut the insulation to the desired length.The most important place in the preparatory process is the preparation of the surface: it must not only be well cleaned of dirt and dust, but also thoroughly degreased. Traditionally, the tape is glued from left to right and from top to bottom, that is, on the sides, the pasting must be started from the top corner. Gradually, little by little, the protective layer is removed from the sticky side of the seal, the tape, without stretching, is fixed on the surface, and only after it is fully fixed, you can release a little of the adhesive tape again and fix it further. The step is approximately 10 cm.

- On nails or screws. This option has not been very popular lately, since adhesive tape or glue is a good alternative to nails. In some cases, it turns out to be impossible to install a self-adhesive sample (for example, if the surface is uneven or the seal is too heavy), and then the traditional nails are remembered again. The distance between the nails is 5-7 cm, less often it is not recommended to install fasteners, as sags may occur through which cold air will enter the room. When installing insulation on self-tapping screws or nails, you need to act very carefully, since if it is not enough to deepen the caps, the door will be difficult to close or not at all. The option is mainly suitable for entrance doors, and in the case of interior doors, it is better to do without a seal at all than to choose a fastener on nails.

How to choose the right door insulation?

Before buying a seal, it is recommended to carefully read the reviews about a particular model. As a rule, the opinion of ordinary people on the street turns out to be more truthful than the advertising stories of the selling staff.

Also, before buying, you need to check the material yourself as follows:

- Feel the cord. It should not be sticky or deform too easily, otherwise all the signs of a poor-quality product are present. Feel free to refuse to buy, even if it is distinguished by an extremely attractive price: such a model will not serve you for a long time and will not protect the premises properly.

- Having chosen an ordinary sealant that is attached to glue, be sure to specify which glue can be used and whether it is available. This issue is especially relevant if an element is selected for metal entrance doors, since the glue must cope well with all negative environmental influences and not become limp. The best option is a silicone sealant, which is suitable for exterior iron or steel doors, and for glass, and many others.

- Read the label very carefully, it is on it that information is often written that the seller or the advertisement will not tell you. If you are looking for a model for sliding sliding doors, swing doors, "accordions" or other unusual options, it will be on the label that it will be said whether the sample is suitable for use with such models.

- For a balcony door, it is advisable to install the same strong seals as for street doors. This is due to the fact that in both cases it is necessary to protect the room from outside influences, and reliable protection does not fit in this.

- For a wooden door in a log house, the use of silicone insulation is a good solution. Pay attention to how easy it is to replace one model with another. Wooden houses "sit down" over time, and after a few years, the door will be difficult to close, then it will be necessary to replace the existing sample.

- For wooden doors in ordinary houses, the installation of mortise seals, which are almost invisible against the background of the door, is very popular. If possible, it is recommended to choose this particular contour option, as it will provide you with good sound insulation, and if the door cracks, the seal can be simply removed without harm to aesthetics.

- It is imperative to select a seal to match the door structure, so that it looks as organic as possible against the general background and does not spoil the whole look.

How to attach the door seal, see the video below.

The comment was sent successfully.