Features of door handles with locks for interior doors

Door handles with locks are an integral part of the fittings and are actively used for installation in interior doors. The models are distinguished by simplicity of design, ease of use and wide consumer availability.

Peculiarities

Handles equipped with a locking mechanism appeared in the second of the last century and were immediately appreciated. The scope of the pens is quite wide. The models have found their application in living quarters, public spaces, offices and in production. Initially, handles with a lock were installed as a cabinet option in clinics, preschool institutions, schools and universities. That is, in protected buildings, where the restriction of access to any room is rather of a preventive nature.

Such models were not used as the main locking device. This is due to the low burglary resistance of products, as well as minimal protective properties. Today, handles with a locking mechanism can be seen not only in public spaces: they are often installed on interior doors in apartments, in bathrooms and toilets. Installation of handles with a locking mechanism is carried out by inserting the device into the door leaf and requires certain skills.

Varieties and their structure

Door handles equipped with a locking mechanism are classified according to several criteria, the fundamental of which is the type of design.

Push Models

This type of device is the most proven and reliable. Structurally, the lever handle consists of a square rod passing through the door leaf and latch, locking springs that secure this rod, a locking core, a locking bolt and handles. On the reverse side, the rod is equipped with a locking washer, thanks to which, with the help of two bolts, both handles are attracted to each other and fit snugly against the canvas.

The design feature of lever handles with a locking mechanism is the presence of a blockerthat secures the rod with a steel hook. The lock is activated by means of a valve or a button, by pressing or turning which it will not work to open the lock without using a key from the back side. The valve closure is usually located at the end of the rod opposite to the keyhole. Pushbutton locks can be placed below the lock mechanism and latch and directly below the swing handle.

The principle of operation of the lever handles is quite simple: when the handle is pressed by means of the transfer plates, the latch is triggered, presented in the form of a locking tongue or, as the common people say, "dogs". It goes inside the locking mechanism and allows you to freely open the door. When closed, the beveled edge of the tongue slides smoothly into the groove and, thanks to a spring mechanism, returns to its original position. The push models are available in two modifications.

The first type is represented by products with separate functions of a latch and a lock., which are installed separately and each have their own decorative strip or rosette. In models of the second type, both devices are located under one cover plate and are mounted as a single unit.The advantages of push devices include high reliability of the latch and locking mechanism, low cost and a huge assortment with a wide variety of colors and designs. Among the disadvantages can be noted the loud actuation of the metal "dog", which somewhat limits their use in children's rooms and bedrooms, as well as the rapid wear of the spring mechanism.

Magnetic models

These are new generation locking devices; they lock the door leaf according to a principle similar to the principle of operation of magnetic latches on wardrobes. Structurally, such products consist of two permanent magnets, one of which is located in the niche of the door frame striker, and the second, made in the form of a movable crossbar, is located inside the case of the locking mechanism.

The principle of operation of a magnetic lock is as follows: when the door is closed, a stationary magnet installed in the box attracts and reliably holds the second one located in the door leaf. When the handle is pushed, the magnets are released and the door opens.

The advantages of magnetic models include simplicity of design, including the absence of a spring mechanism. In such models, in principle, there is nothing to break, which significantly increases the reliability and durability of the devices. In addition, the absence of a "dog" allows you to completely hide the mechanism in the door leaf, making the process of opening and closing the door completely silent. Magnets for interior locks are made of stabilized ferrite. Thanks to this, magnetic devices are able to serve for more than a dozen years without the risk of losing their basic performance. In addition, most magnetic locks are manufactured in the same sizes as mechanical models.

This greatly facilitates installation and allows you to independently replace the mechanical model with a magnetic one. Typically, the product is installed in existing niches or grooves and fixed with fasteners. However, along with a large number of clear advantages, magnetic locks also have some disadvantages. For example, structures are often non-separable, and in order to correct the operation of the magnet, it is necessary to completely remove the lock, while destroying the door leaf. In addition, due to the specific properties of the magnet, a constant magnetic field is formed within a radius of 30-50 cm from the lock, which is capable of attracting electrified particles, pins and needles to itself.

There is also a high probability of slamming the ajar door, which is fraught with unpleasant consequences. Slamming is due to the fact that the operation of the magnetic device begins when the magnets are at a distance of 15 cm from each other. The mechanism in this case operates on the principle of a door closer, slowly pulling and then slamming the door with force. However, this problem can be completely solved by inserting a reverse-acting lock. The essence of the operation of such a device lies in the use of multi-pole magnets, which do not attract each other, but, on the contrary, repel.

To close the door, lower the handle: when it is turned, the magnetic bolt will be tightened, the rod will freely enter the cavity of the striker and will be unloaded as long as the door remains in the closed position. As you can see, the effect of a door closer in such devices is completely absent, so there will be no need to worry about spontaneous slamming of the door.

The negative aspects of using magnetic locks include their low ability to withstand shock loads and crack even with minor impacts.

Knob pens

Unlike push models, the control of the "dog" in such devices is carried out using a rounded handle that can rotate around its axis.The most common places for knob installation are shower rooms and home bathrooms. However, in such rooms, handles are used, equipped only with a latch and a lock. The key cylinder and the borehole are absent in them, since they are not necessary at home. Office space is another matter. In them, knobs with locks are often installed both on toilets, when they want to restrict the entry of unauthorized persons, and on offices.

Installation of knobs allows you to close the room from the inside, and, if necessary, block the lock or latch. As a result, only a limited circle of people who have keys to the locking device will be able to enter the premises. The advantages of knobs include very simple installation and low cost of products.

Among the disadvantages are low burglary resistance and the inability to open doors with busy hands. And if in such cases it is enough just to press on the lever with the elbow, then to open the spherical device it is necessary to fully rotate the knob.

Lockable handles for sliding doors

In terms of their design and appearance, such options are very different from previous models. A characteristic feature of such devices is their location on the door leaves: the products are completely recessed into their surface, so that compartment doors can easily hide in door niches. Such handles are also often equipped with a locking mechanism that provides a secure locking by means of a latch. Such structures are capable of closing only from one side, which is why the scope of their use is rather limited.

Materials (edit)

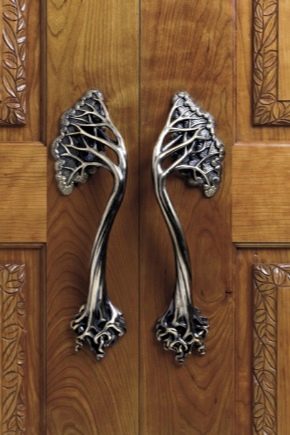

Handles designed for interior doors do not require the use of particularly durable materials, as required by models for entrance groups. Such products are not subject to increased requirements for burglary resistance and security, therefore, more attention is paid to the decorative component. In the manufacture of pens, a combination of several materials is often used, which allows you to create interesting images and noticeably enliven the interior. The main materials for the manufacture of door handles are metal, plastic, wood and glass.

Plastic products are widely used for low traffic interior doors. These can be archives, book depositories and other premises that do not involve intensive movement of people. The advantages of the models include low cost and a wide range of designs and colors. The disadvantages are the short service life and the rustic appearance of plastic structures.

The metal is most commonly used to make handles. Steel models are considered the strongest and most durable. They are distinguished by the reliability of the locking mechanism and are intended for installation on doors located in busy places. In addition, the steel surface is often chrome-plated or brass-plated, which gives the products a beautiful and modern look. The steel handles are highly resistant to corrosion and can be installed in rooms with high humidity. The disadvantages of steel products are the high cost and high weight.

Products made of copper alloys and aluminum are also highly durable and can last for 5-8 years. However, when buying them, you should make sure that the product does not turn out to be hollow, since such a design, despite its low cost, is not a good solution for such devices. From above, alloys are often coated with gold, silver and bronze paint, due to which they begin to look quite rich and noble. The disadvantage of sprayed metal handles is the low wear resistance of the decorative coating, due to which the paint is quickly erased and the products lose their original gloss.

The wood has a natural and natural appearance, it is mainly used for the production of press models.The advantages of the models are environmental friendliness and material pleasant to the touch, and the disadvantages include the inability to use in wet rooms and the high cost of some models.

Glass is used to make knob handles. Such models are distinguished by a stylish and aesthetic appearance, as well as a long service life with careful handling. The disadvantages are low shock resistance and the need for regular maintenance of the products.

Selection recommendations

The main condition for a successful purchase is the correct choice of the type of control of the lock device and latch. When choosing between a knob, a push device and a magnet, first of all, you should focus on the size and weight of the door leaf. So, for light MDF doors, an aluminum or plastic knob handle is quite suitable, while it is better to install a push or magnetic mechanism on heavy canvases made of natural wood or simply oversized doors.

The next step in the selection should be to assess the quality of the purchased model. First of all, you should pay attention to the correct operation of the locking mechanism: it should not dangle, and the latch should not jam. For models with spraying, you need to check the uniformity of coloring, and on chrome-plated products, make sure that there are no scratches and chips.

A competent choice and careful operation will significantly extend the life of the locking device and make the handle convenient and comfortable to use.

How to install door handles in interior doors with your own hands, see the next video.

The comment was sent successfully.