Features of garage hinges and their varieties

Correctly selected and installed garage door hinges are the key to smooth door opening. In addition, the presence of such an element ensures that there will be no distortions in the future. A distinctive feature of these products is that they ensure the sealing of the doors, and also help to reduce the humidity in the room. However, in order for the fixation elements to be able to fully cope with the tasks assigned to them, you need to choose and mount them correctly.

Main characteristics

On the modern market, there are many hinges for garage doors, which differ in the material of manufacture, sizes and shapes. In the selection process, all points must be taken into account, since only in this case it will be possible to choose the optimal and long-term option.

Dimensions (edit)

In order for the hinges to be able to cope with the retention of the metal sheet, you need choose their size correctly. At the same time, close attention is paid to the clamps, the size of which varies in the range of 10-32 mm. The diameter step is 22 mm, so that everyone can choose the most optimal option for a garage door.

In the process of choosing the most optimal size, it is necessary take into account factors such as reliability and comfort of use. Very often, a situation occurs with garage doors when they simply jam at the moment of opening or closing, and it takes too much time to fix the problem. In order to prevent this from happening, the dimensions must be selected in such a way that there is always a gap of 0.1-0.2 mm.

Besides, when choosing the size of the loop, you should also take into account the materialwhich was used in the sash manufacturing process.

The quality characteristics of the canvas also affect the number of loops, which can be from 2 to 4.

Materials (edit)

Today on the market you can find hinges of various options, however, garage models are usually made from a metal profile. In addition, the optimal material for obtaining this element is steel, both black and low alloy. In the process of choosing the luting material, it is necessary to take into account steel grade, otherwise, you can get problems during the welding process with the frame of the garage door.

If during the production of the buttonhole was used black steel, then it can only be welded using electric welding through processing around the perimeter. As for the hinges made of alloyed materials, then for their welding is used argon welding.

It should be noted that it almost doesn't matter what material will the loops be made of... The only positive point of using steel options is that they do not corrode, therefore they have a longer service life.

However, the cost of such hinges is significantly higher than options that are made from a conventional metal profile.

Varieties

Currently, companies produce many hinge models that differ in their shapes, production material and other characteristics, thanks to which everyone can choose the most optimal option for their garage.

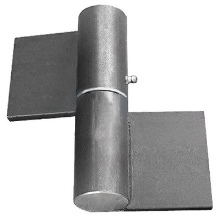

Some of the most popular and demanded today are cylindrical models, which include two components.The first is distinguished by a small depression, where it is necessary to put the pin located in the second part. A distinctive feature of such a loop is presence of a metal ball, which greatly simplifies the process of flap movement.

Some models of these hinges differ the presence of a support bearing, which plays the role of a ball. The main advantage of this variety is that it is able to cope with colossal loads. That is why they are chosen for doors weighing up to 400 kg.

In this case, it all depends on the dimensions of the cylinder, because the larger it is, the more mass the loop can handle.

Another fairly popular option is reinforced cylindrical models, in the production process of which the thickest metal is used. Due to the fact that the thickness of this metal is less than 4 mm, it can perfectly cope with any assigned tasks and colossal loads. In addition, the use of such a design makes it possible to evenly distribute the load, significantly increasing the reliability and strength of the hinge.

These hinges are recommended for use on garage doors, the weight of which varies from 400 to 600 kg. Some craftsmen make cylindrical reinforced hinges on their own, simply by adding metal plates to the usual ones.

If it is necessary to ensure maximum safety of the garage and its inaccessibility in front of intruders, it is worth choosing through loops. They consist of two halves and a pin, which serves as a connecting element. The first part will need to be attached to the gate frame, and the second is connected to the sash. For maximum security, it will be necessary to mount small plates around the edges of the pin, thanks to which burglars will not be able to reach the mechanism.

In the absence of such an opportunity, you can simply install a special limiter on the upper part, which will not allow the pin to rise up.

The only one flaw of such hinges is that they are not able to cope with heavy loads, therefore they cannot be used in combination with heavy gates. But with light models, they will cope with a bang, which is especially beneficial, given the affordable cost of the device.

In the modern market, you can also find 3-section overhead hinges, which boast increased durability and reliability. A distinctive feature of such models is that they are able to cope with excessive loads, so the mass of the doors does not matter. 3-section hinges include 3 parts, and the middle one is characterized by the presence 2 heavy-duty pins. This loop is so strong that it will not be possible to remove it without a grinder.

The most expensive and reliable on the modern market are considered hidden garage hinges. The main advantage of such products is that they cannot be seen even with closed doors. This effect is achieved not only due to the design features of the models, but also due to the unique installation. Hidden hinges are attached to the inside of the frame, making it impossible to reach them from the outside.

There are many designs of such hinges, and it is worth choosing a certain option depending on the features of the gate.

Form overview

Modern companies offer customers many forms of hinges, each of which has its own unique characteristics, strengths and weaknesses. In the process of choosing the most optimal option, you need to take into account the totality of characteristics, as well as the load that will be created by the doors. Among the most popular and demanded on the market are the following.

- Cylindrical Is a fairly common option that is used for standard swing gates.A distinctive feature of such hinges is that the bearing is inside. During operation, close attention should be paid to the mass of the doors, which should not exceed 400 kg. Otherwise, the hinges may simply fly out when the doors are opened or closed. There are several classes of cylindrical hinges on the market, depending on which the ability to cope with loads varies. The demand for this option is dictated by its high strength, as well as ease of installation on the frame.

- Square... They boast a larger surface contact area. Thanks to this, the installation process is quite simple and can be carried out using a conventional welding machine. In addition, such hinges are able to cope with heavy loads, which favorably distinguishes them from other options. The unique design features of square hinges make it possible to use them not only for garage doors, but also for gates and other similar structures. In the manufacturing process of this element, galvanized metal is used, which is famous for its strength and low weight.

- Hexagonal options can be seen extremely rarely, since their installation requires the welding of metal ears. The only advantage of this method is that it further greatly simplifies the installation process. It is necessary to select such hinges depending on the design features and the mass of the swing gates. Moreover, such products are able to cope with increased loads. Standard, unreinforced versions can be easily installed on garage doors weighing 400-500 kg.

- Teardrop loops have a uniform weld seam. It should be noted that only those hinges that have built-in bearings can have a teardrop shape. This option is distinguished not only by its attractive appearance, but also by the ease of installation, which became possible due to the unique design of the product. If the garage doors are characterized by large dimensions, then it is best to use hinges with a diameter of 30-32 mm, and the length does not exceed 2.5 cm. The length of the teardrop-shaped loop is extremely important, since it is this hinge that affects the length of the weld.

Installation

In order for the hinges to be able to fully perform the functions assigned to them, you need to pay close attention to the process of their installation and adhere to the following rules.

- If welding will be carried out, then the parts should be tacked in advance in different places. Only after that you can check how well the hinges are in place and whether the garage door will work as the owner needs. If the flaps move correctly, the welding process can be completed.

- In order to prevent the appearance of distortions, it is necessary to apply the welded seams in a checkerboard pattern. In addition, it will greatly enhance the strength characteristics.

- In no case should the hinges be welded in one go. You can't rush so that they have time to cool down. Otherwise, this may negatively affect their strength characteristics. In addition, a gradual installation technique will allow installation in such a way as to ensure maximum product durability.

- The working surface during the installation process must be clean, without paints or traces of other substances that can ignite.

Care secrets

With proper care, these elements of swing garage doors can last a long time. The main problem is that the hinges wear out due to improper installation, which leads to uneven distribution of the load. Besides, it is necessary to lubricate the hinges in time and ensure their protection from negative external influences.

If steel was not used in the production of hinges, then you will also have to make sure that protect them from corrosion. When she appears get rid of rust you can simply remove it with a special lubricant.

Thus, there are many types of garage door hinges on the market today, which differ in their appearance, characteristics and installation features. A specific option should be chosen based on the parameters of the mass of the doors and their design.

In addition, it is best to choose welded hinges that are made on the basis of GOST.

You can find out how to weld hinges on a garage door from the video below.

The comment was sent successfully.