Description and installation of ombre loops

Furniture production cannot do without the use of hinges. Different types of furniture and different purposes require different fixtures. So, for folding tables, you will need lombard loops. They will be discussed in the article.

Features and purpose

When choosing fittings and fasteners, one must take into account their quality and purpose. It often happens that specific structural details are suitable for certain products. For example, for folding tables, it is precisely the lombard loops that are needed.

Any furniture hinge can be described as a semi-mechanical part that serves as a connecting device. A hinge is needed to fix the door, front or table top to the body of the furniture product, with its help its hinged part will easily open and close. Lombard hinges are usually used to attach folding parts, allowing the sash to open 180 °. Therefore, such hinges are often used in the manufacture of folding tables.

Although the design features of book tables do not allow these fasteners to be completely hidden, they are easy to decorate.

Lombard loop has many useful characteristics:

- provides a wide opening angle of the flaps;

- has a long service life;

- provides a high level of ultimate load, which means a large number of operating cycles;

- allows you to gently and smoothly open the sash;

- has good strength, wear resistance;

- not subject to deformation;

- groove fasteners do not allow the sashes to loosen;

- has anti-corrosion properties;

- the hinge is easy to install and dismantle.

When buying, you should be aware that a high-quality part does not squeak, has no external damage or scratches. And also it is worth paying attention to the package bundle. There must be 2 parts: a functional fastener and a bezel blank.

Furniture hinges can be made from different metals. It is better if the material for their manufacture is steel or brass. However, it is worth considering that it is not a good solution to install furniture with steel parts in rooms with high levels of humidity.

There are also products with chrome plating. They are much more resistant to moisture.

What are they?

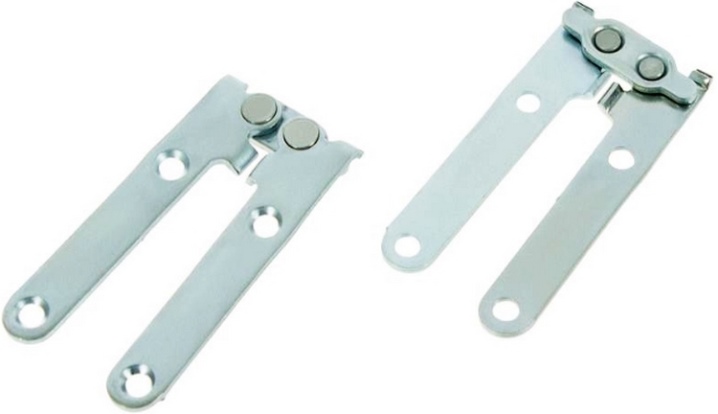

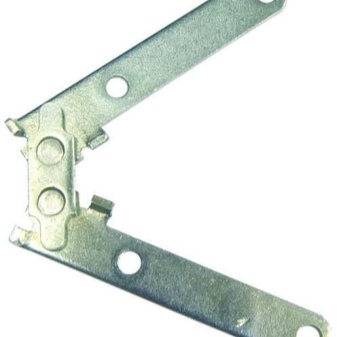

Lombard loops are cylindrical overhead and inset. Overheads are installed on the ends of the sash in cases where the facades are thin, and installation of mortise elements, which are less noticeable on furniture, is not possible. The cylindrical hinge is convenient in that it can be hidden inside both the end part and the folding part of the product. Zinc is often applied to the hardware, which reliably protects metal structures from corrosion, and it can also be made of a zinc alloy.

The cylindrical hinge has design features. It is a rotary device, it cannot withstand a heavy load, therefore it is not used for overall structures. However, the metal part will be hidden when the table is unfolded, which will provide an attractive appearance to the product. Cylindrical hinges can be used for different facades: chipboard, MDF, solid wood.

The size of the products may vary. It is indicated by markings, for example D12, D14, D16, D24.Quite often, the version with a diameter of 14 mm is used, since this value is optimal for the thickness of the canvas from which the folding tables are made.

Installation

You can install the cord loop yourself at home. First of all, it is worth preparing the tools:

- pencil and ruler;

- screwdriver, awl, screwdriver;

- self-tapping screws;

- end mill.

The work is done step by step.

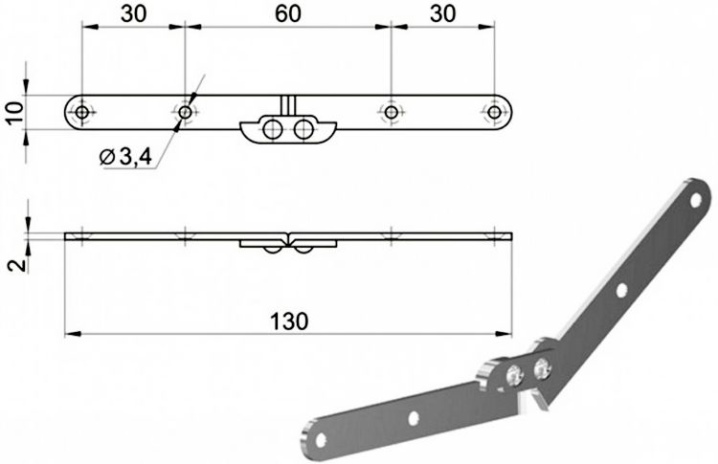

- In order for the flaps to unfold well without friction, you need to correctly mark the places where the screws will be screwed. For this, lines are drawn at the ends of the blanks, which must pass strictly in the middle of the ends. From the edges on the lines, measure 22 and 60 mm, mark the points with an awl. If the work is carried out on chipboard, it will be advisable to drill holes for the screws in advance to prevent splitting of the material.

- Then the loop is screwed to the ends with the reverse side. In this position, the hinges check how the structure works, whether there is friction, if necessary, adjust the position of the part to eliminate defects.

- Using a sharpened pencil, mark the location of the loop and remove it.

- The resulting markings are milled. The depth of the grooves at the edges is 4.5-5 mm, then 2-2.5 mm.

- The loop is screwed on the right side.

To prevent chips and not damage the surface, the cutter must be well sharpened, and the screwdriver must be held exactly in a vertical position during operation. When installing the hinge, care must be taken that the gap between the flaps is not too wide. To improve the aesthetic appearance of the finished product, an edge made of a special material can be glued to the ends.

For the installation of inset hinges at the ends, markings are made for the cylinders, then holes of a suitable diameter are drilled.

To increase load carrying capacity and increase strength, the cylinders can be inserted with adhesive. Then they need to be fixed using expansion screws or self-tapping screws.

For more information on ombre loops, see the video below.

The comment was sent successfully.