All about door molding

Correctly selected interior doors not only provide the necessary privacy, but also visually push the boundaries of the space. However, this structure is subjected to intensive use every day, therefore it is important to pay attention to the quality of the canvas itself and other components.

In our review, we will tell you about the door molding, its features, varieties and subtleties of choice.

What it is?

The door molding is an element of the box structure of the door module, it allows you to fix the sashes and aesthetically design the opening. Typically, door manufacturers offer modules of standard sizes that can be installed in all rooms without exception. If, for some reason, the opening differs in size from the installed door leaf, then you should take care of buying molded products. They include several configuration options, each of which performs its own special function.

Platbands

Frame element in the form of a plank. It is attached to the door frame and decorates the area where it is attached to the wall. Along the contour of the doorway, the platbands form a rectangle - due to this, the gap between the wall surface and the extrusions is practically invisible. This gives the door unit a finished look.

Usually platbands are chosen in tone with the canvas itself, or, conversely, made in contrasting ones. Models on veneer have become widespread.

They can be flat, curly, telescopic, most often they are made overhead.

Door accessories

This type of molding is necessary if the wall thickness is greater than the width of the door frame. In this case, when installing the door, part of the wall remains undecorated, and this worsens the general appearance of the room, makes it untidy. Thanks to the additions, the drawback is easily leveled, the structure fits organically into the opening, making up one whole with the platbands. Dobors are fixed so that there is no free space between the frame and the platbands. A pleasant bonus will be the fact that when fixing the extensions, there is no need to plaster the slopes, and this significantly reduces the overall cost of repairs.

Considering that the add-on should form a single module with the door leaf, you need to select it in the same shades as the door leaf.

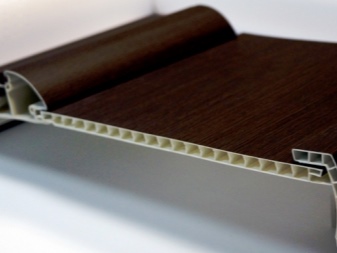

Cover strips (pretend strips)

Such molding is necessary when installing double-leaf doors. It masks the gap between the flaps. Usually it is fixed on one part of the canvas so that it goes 1-1.5 cm beyond the contours and covers the edge of the adjacent sash. The fixation is carried out from the outside so that the bar does not interfere with the free opening of the door.

The element is selected in the same range as the door leaf, and the width is calculated in such a way that the strip does not interfere with the installation of door fittings. The surface of the false plank can be flat or embossed. Installation is carried out using nails without heads.

Frame

This is the most important element of the door construction. The door frame is fixed to the walls with elongated nails. This element is subject to increased strength and wear resistance requirements. Telescopic moldings are traditionally made of solid wood veneered with oak or linden.

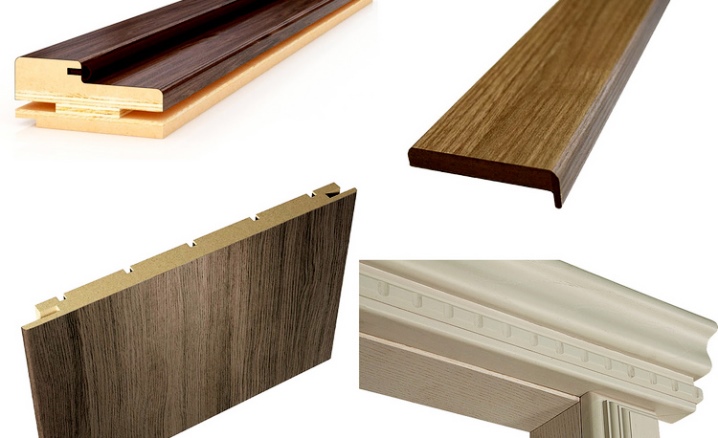

Views

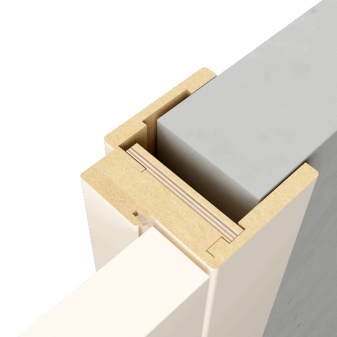

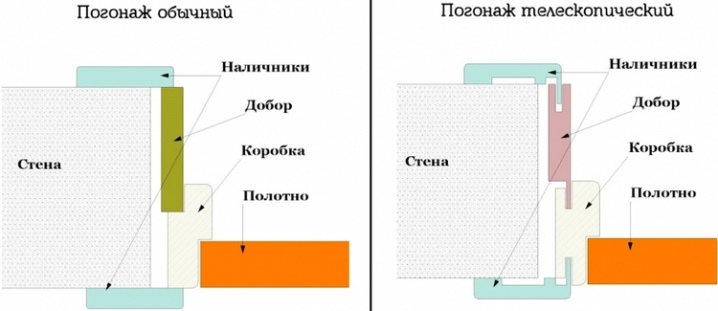

Molded products are standard or telescopic. The standard one has a typical design, which is fixed to the base with glue or nails without heads. Telescopic ones are more complicated, they provide for special grooves for fixing extensions and platbands. Usually, such platbands are L-shaped, and a special shelf allows you to adjust the required width of the door frame. The end pieces are also equipped with a groove, thanks to which it is possible to adjust the opening of any depth.

The telescopic structure is finished using high quality paints and varnishes.

A good solution would be the use of coplanar moldings, it allows you to visually hide the door frame with a casing, giving the structure an aesthetic look. The advantages of this solution include:

- saving space;

- duration of operation;

- noiselessness;

- the ability to mount the canvas without thresholds.

Coplanar moldings can be installed in any premises. It looks especially stylish in interiors decorated in the empire, grunge, provence and baroque styles.

Materials (edit)

Most often, box moldings are made of wood - solid wood or glued wood. The advantages of natural material include a pleasant smell, noble color, decorative texture and environmental safety. Most types of wood have high sound insulation. The disadvantages include low water resistance - when buying moldings for a bathroom, an expensive impregnation will be required, otherwise the material will quickly deform and become a breeding ground for fungus and mold. In addition, wood is always expensive, the installation of such a door structure will eventually result in a significant amount.

The greatest demand is for wood from chipboard and fiberboard. These are inexpensive and easy-to-use materials, they have low thermal conductivity and high sound insulation. However, in their production, a large amount of glue is used; when heated to a certain temperature, it releases volatile toxic substances and becomes hazardous to health. MDF is considered a more environmentally friendly alternative, but the strength of this material leaves much to be desired.

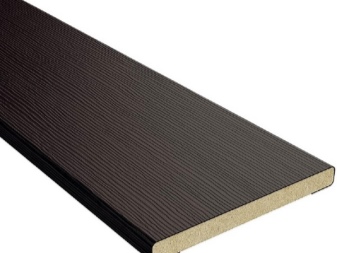

In recent years, WPC, a wood-polymer composite, has become widespread. It combines all the advantages of natural wood and polymers, is durable, resistant to aggressive external factors and mechanical damage. In addition, it has a beautiful appearance and is pleasant to the touch.

For the installation of glass doors, metal moldings are used, most often aluminum. It blends effectively with modern interiors, lending elegance and sophistication to design.

How to choose?

When buying moldings, very often buyers are faced with the question of choosing between simple and telescopic models.

Telescopic moldings have a number of advantages in comparison with simple ones:

- thanks to the use of hidden fasteners, the door module can be assembled without screws, nails and glue;

- telescopic moldings can be mounted when the wall deviates from the vertical axis;

- more spectacular appearance due to the absence of noticeable traces of glue and hardware products;

- the ability to hide any defects around the door frame if the walls have different thicknesses;

- minimization of repair costs;

- the possibility of soundproofing;

- the system easily adapts to holes of different depths;

- possibility of installation on doors with optional vertical elements.

With such an impressive list of advantages, telescopic moldings have only one drawback - they cost much more than usual. However, the reduction in the cost of finishing the doorway and the time for assembling the structure more than pay off this minus.

For more information on door molding, see the video below.

The comment was sent successfully.